Automatic control method for material taking and feeding operations of full-automatic garbage transport crane

An automatic reclaiming and crane technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve problems such as the inability to realize system functions well, improve work efficiency and mechanism operation reliability, prolong service life, and ensure operation. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In conjunction with the accompanying drawings, an embodiment is used to further illustrate the technical solution of the present invention.

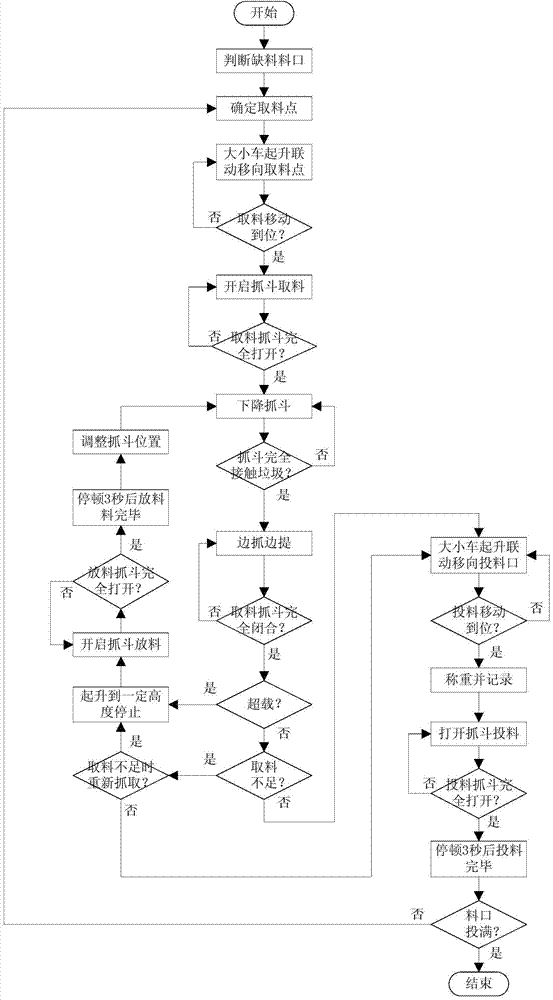

[0068] Such as figure 1 As shown, the automatic retrieving and feeding operation process of the fully automatic garbage handling crane in this embodiment is described.

[0069] The automatic reclaiming and feeding operation of the garbage handling crane means that the control system uses the automatic control method of the reclaiming and feeding operation of the automatic garbage handling crane to realize the automatic operation of reclaiming and feeding according to the information of the lack of material.

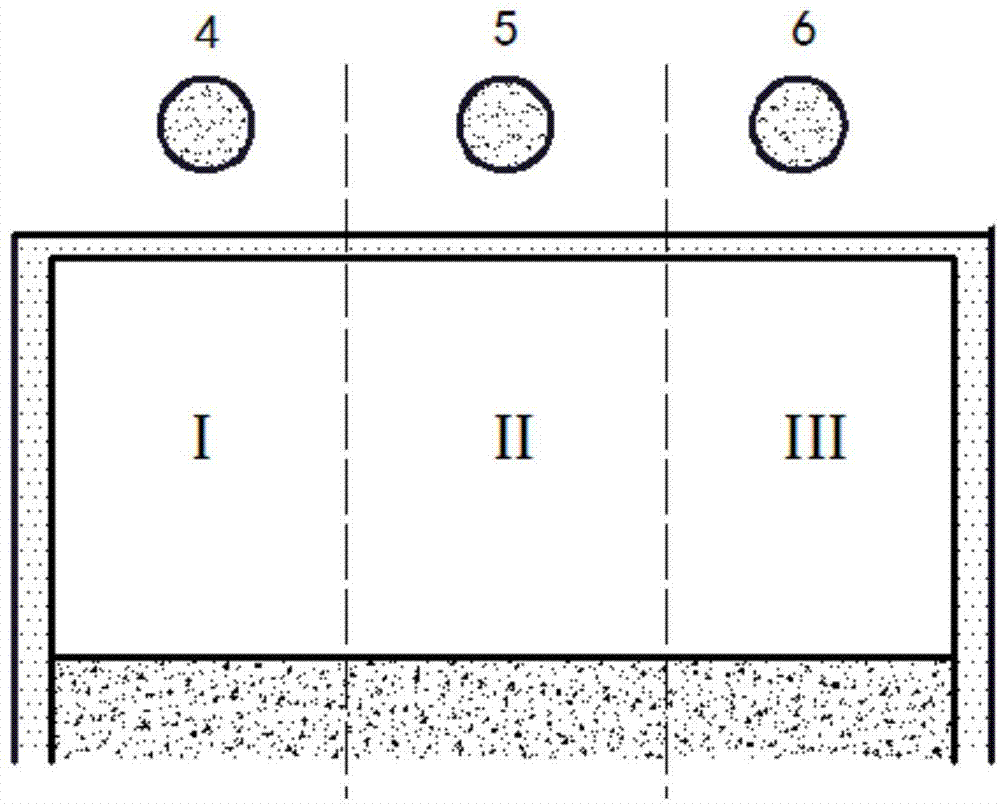

[0070] The lack of material opening information is the selection of the feeding opening by the operator using the touch screen, which is the premise of automatic feeding and feeding. In this embodiment, three feed ports are taken as an example. When the lack of feed ports is determined, the control system will drive the larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com