Method and system for combined supply of cooling, heating and power through small biomass gasification

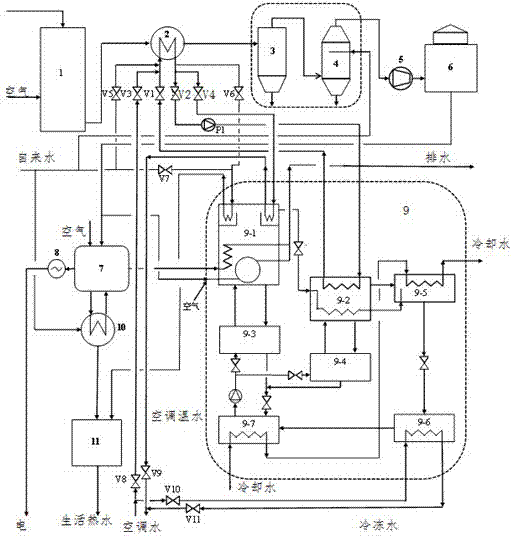

A technology of combined cooling, heating and power supply and biomass, which is applied in the direction of fuel oil systems, refrigerators, refrigeration components, etc., can solve the problems of energy waste and ineffective utilization, and achieve the effect of reasonable system configuration and improved energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

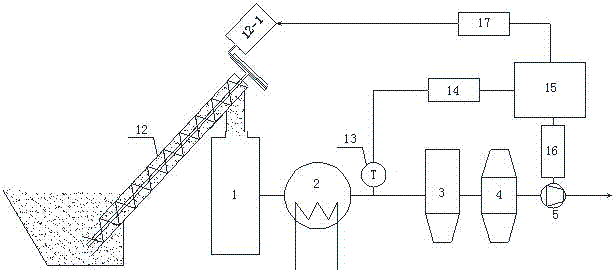

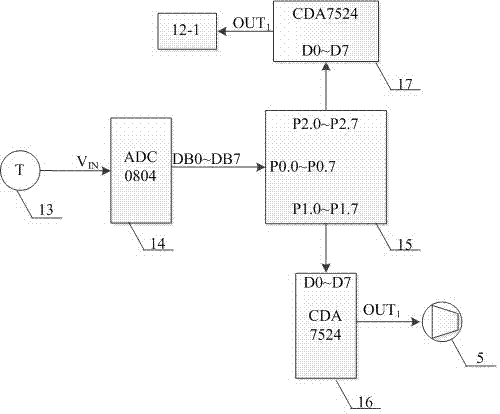

[0025] The invention utilizes the sensible heat of the high-temperature biomass gasification gas coming out of the biomass gasification furnace through the heat pipe type gas-liquid heat exchanger, and can cool the gas for convenient transportation while improving the energy utilization rate of the system. The temperature of the raw biomass gasification gas from the biomass gasifier is 300-400°C or even higher. The raw biomass gasification gas contains impurities such as tar vapor, water vapor, and dust. Because the tar is in a gaseous state above 300°C , below 200°C, it condenses into a liquid state, which is easy to combine with water, carbon particles, etc., and corrodes metals. Therefore, the temperature of biomass crude gasification gas after heat exchange through a heat pipe type gas-liquid heat exchanger drops to 200°C before dust removal purify.

[0026]In order to accurately control the temperature of the raw biomass gasification gas at 200°C, a temperature sensor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com