Efficient heat radiation embedded type microwave oven

An embedded microwave oven technology, applied in the field of microwave ovens, can solve problems such as unreasonable air inlet and outlet design, large temperature difference between furnace door observation window glass, and poor heat dissipation effect, so as to prevent fogging or condensation, improve cooling effect, and reduce The effect of temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

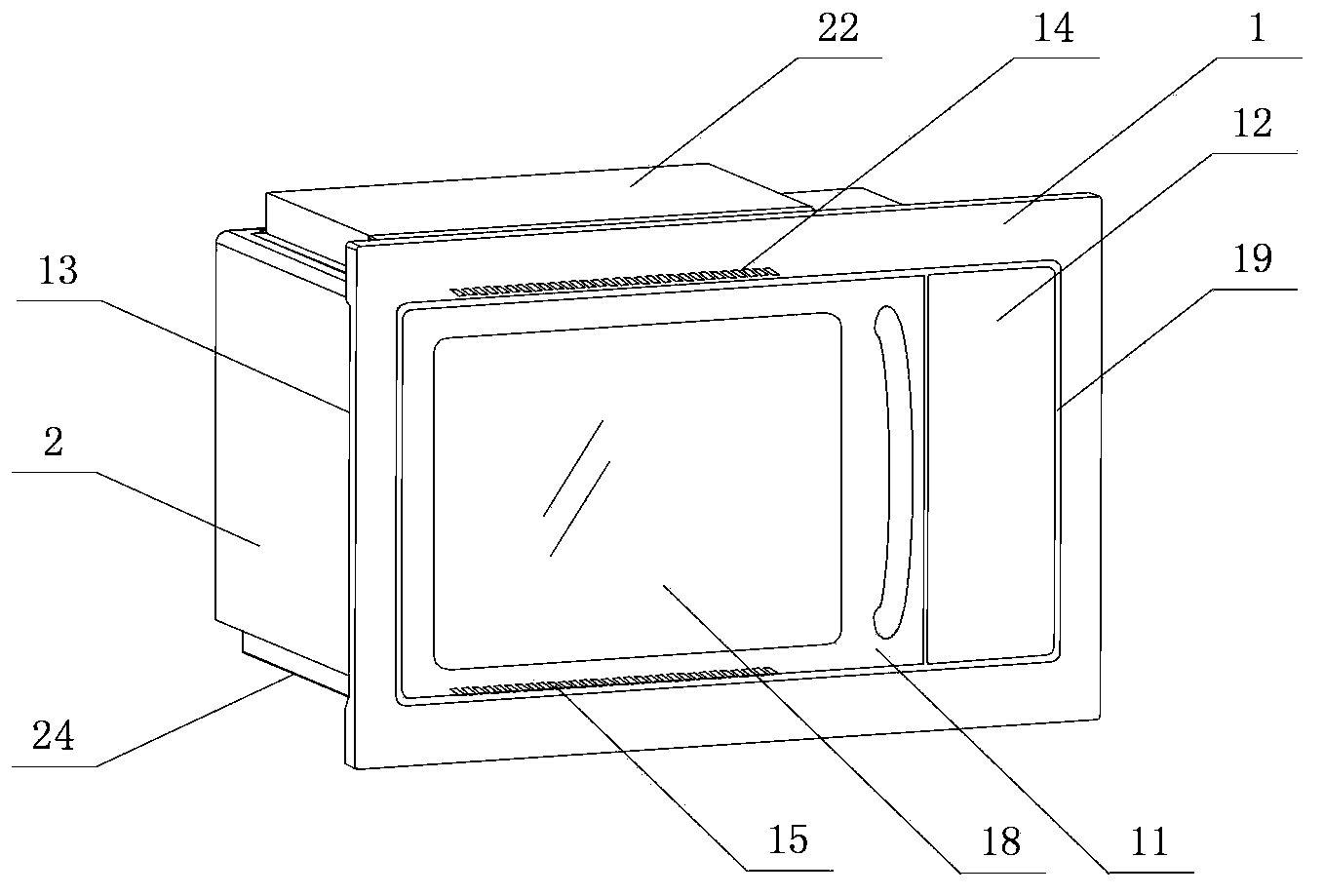

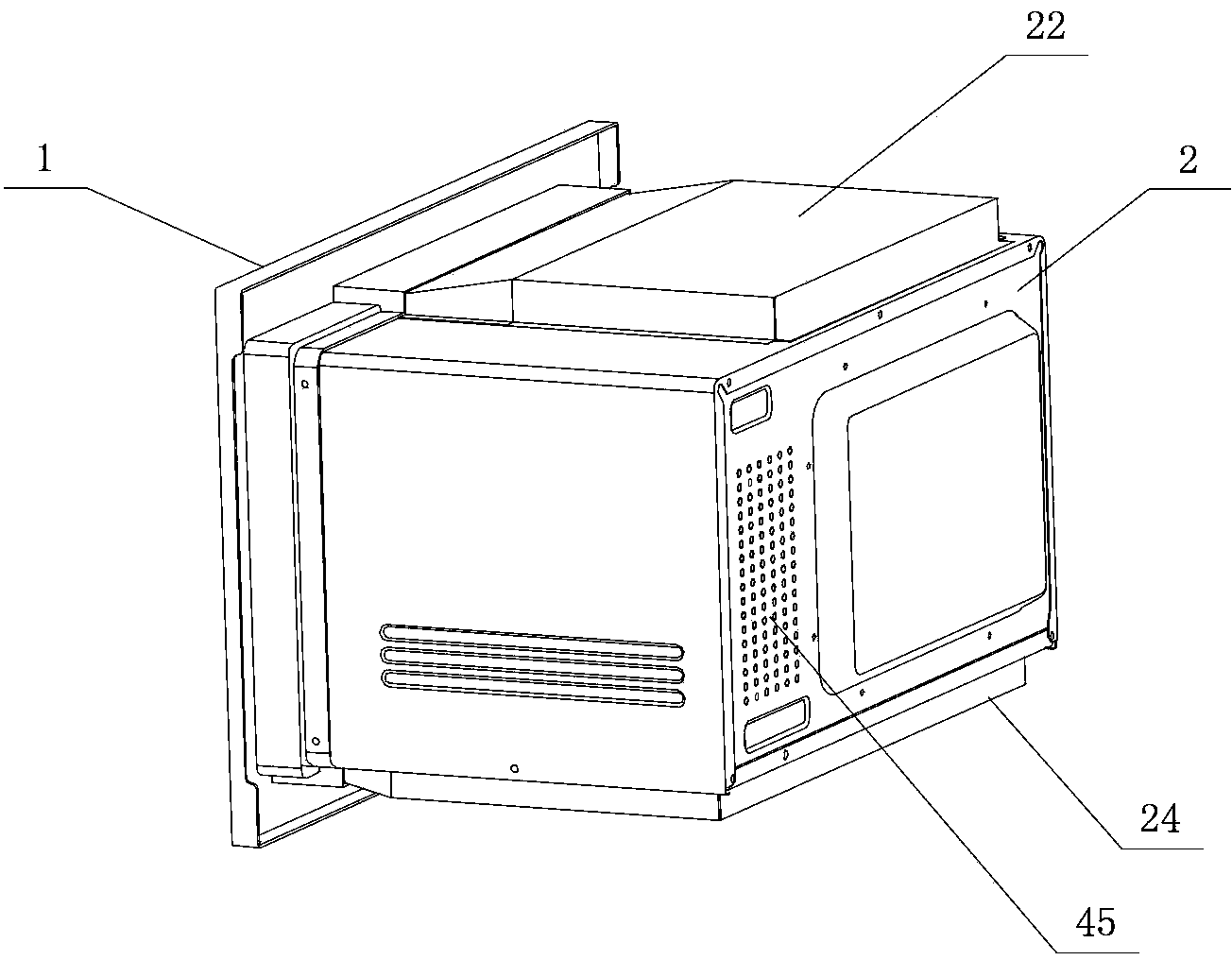

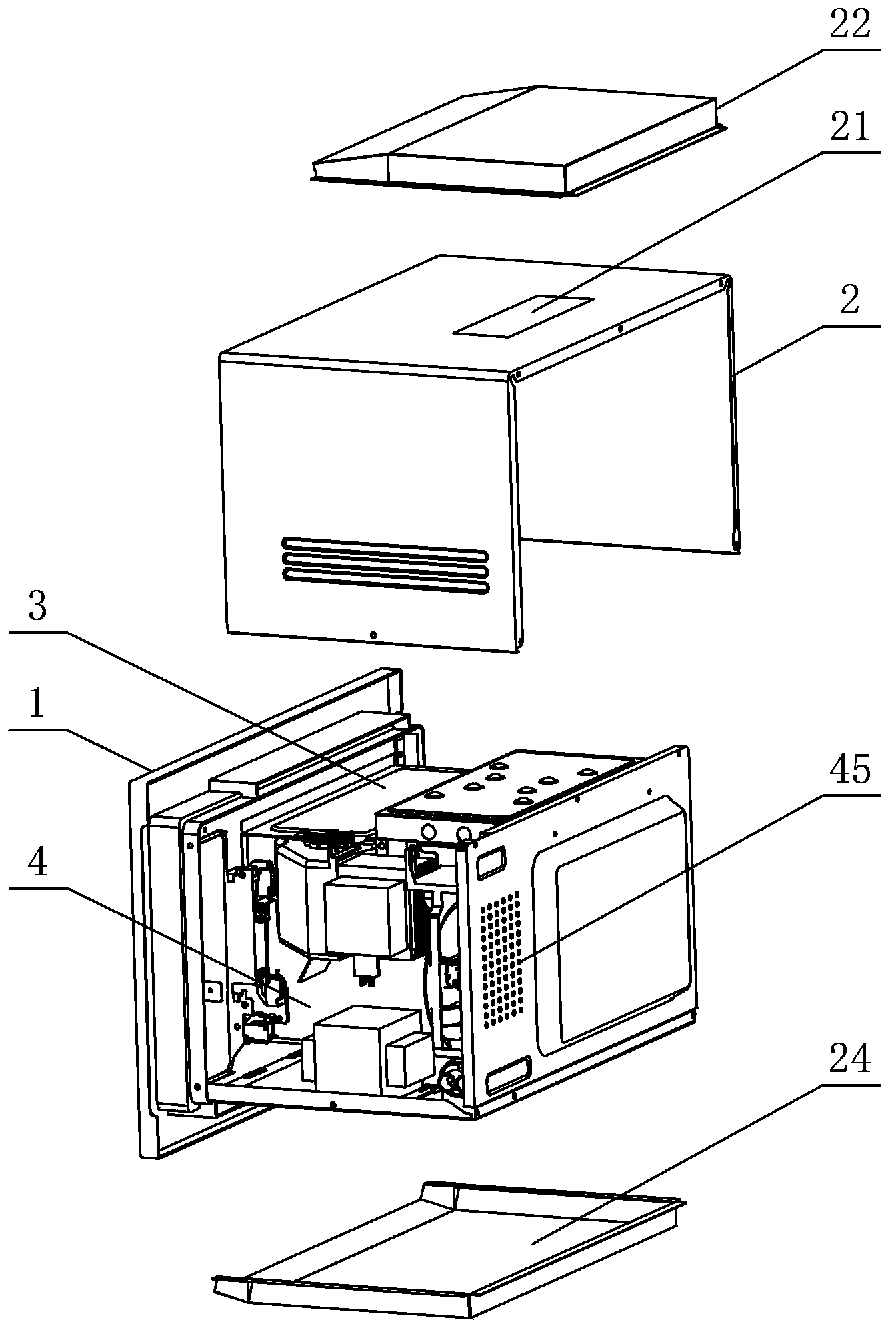

[0027] Embodiment 1: A high-efficiency heat dissipation embedded microwave oven of this embodiment 1 is embedded in the cabinet 5, such as figure 1 , figure 2 and image 3 As shown, it includes a surface frame 1, a casing 2, a cooking chamber 3 and an electrical appliance room 4 placed in the casing and arranged side by side. The cooking cavity and the electrical appliance room have a common side wall panel, and the surface frame matches the reserved hole of the cabinet. The microwave oven is embedded in the cabinet and forms an integral body with the cabinet. The front frame is designed with a furnace door 11 and a control panel 12. There are gaps 19 between the upper and lower end faces of the furnace door and the front frame. Air intake holes 13 are designed on the left and right sides of the front frame. The upper and lower air outlets 14 and 15 of the grille shape are respectively designed on the upper and lower ends of the surface frame. Facing upwards and directly fa...

Embodiment 2

[0029] Embodiment 2: A high-efficiency heat-dissipating embedded microwave oven of this embodiment 2 includes a surface frame, a casing, a cooking cavity and an electrical appliance room placed in the casing and arranged side by side, and an oven door and a control panel are designed on the surface frame, such as Figure 5 As shown, the furnace door is hollow, and an observation window 18 is designed on the furnace door. There are through holes 17 on the top end face and the bottom end face of the surface frame, and the through holes communicate with the hollow cavity 16 of the furnace door. The body communicates with the lower air guide hood through the through hole on the bottom end of the furnace door, and the hollow cavity of the furnace door communicates with the upper air guide hood through the through hole on the top end of the furnace door. Part of the dry and clean cooling air discharged from the lower chamber of the electrical room Directly pass through the lower air ...

Embodiment 3

[0030] Embodiment 3: A high-efficiency heat-dissipating embedded microwave oven of this embodiment 3 is embedded in a cabinet, including a surface frame, a casing, a cooking cavity and an electrical appliance room placed in the outer casing and arranged side by side, and the opening on the back of the electrical appliance room A filter screen is installed at the place, and the filter screen can prevent the cooling fan from sucking impurities, dust or foreign matter into the electrical room to cause a high-voltage electrical short circuit or damage the electrical components, and can also prevent the dust on the surface of the electrical components from causing poor heat dissipation and causing failures. Others in this embodiment 3 Parts are similar to the corresponding parts of Embodiment 1, and will not be repeated herein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com