An insulin injection marking device

A technology of insulin injection and marking device, which is applied in the field of medical devices, can solve the problems of bacterial contamination and bacterial infection, and achieve the effect of not easy to fog, not easy to fall off, and good leveling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

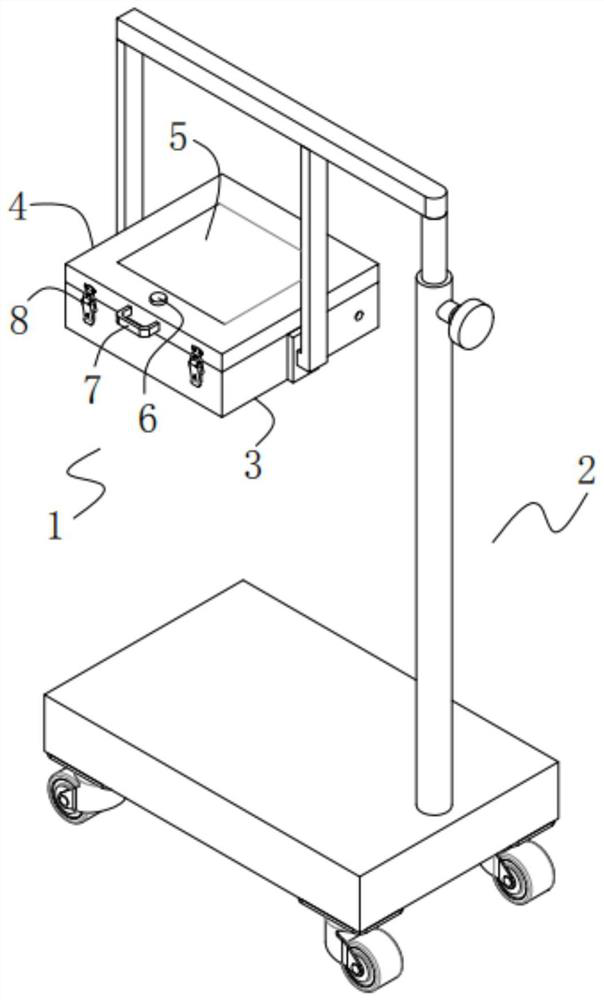

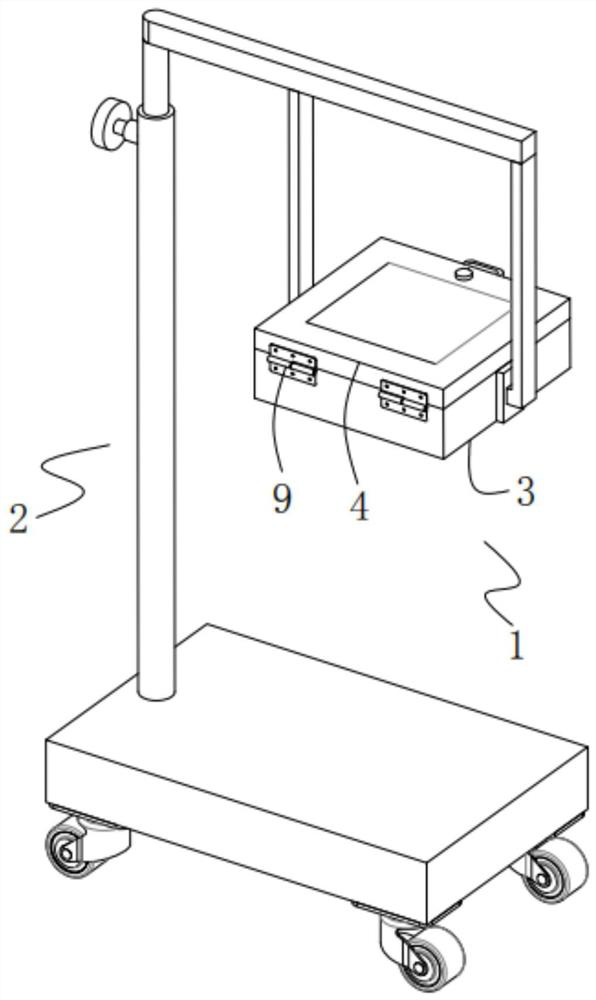

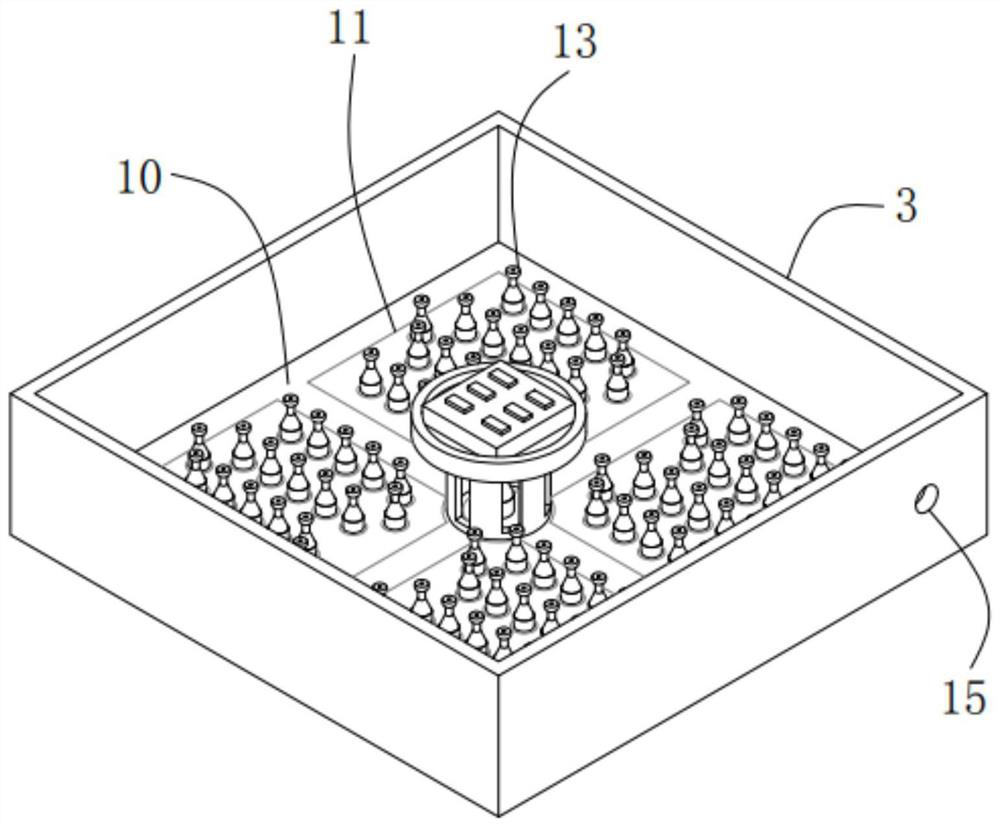

[0059] An insulin injection marking device such as Figure 1-5 As shown, an insulin injection marking device includes a marking part 1, and the marking part 1 includes a box body 3, a box cover 4, a power switch 6, a touch screen 5, a transparent colorless glass plate 10, and several marking points A generating unit 13, a central point generating unit 14, a support cylinder 17, an assembly seat 18 and a controller 19;

[0060] Such as Figure 1-7 As shown, the box body 3 is a square box body, and the bottom wall of the box body 3 is centered with an installation through groove 16, the box cover 4 is arranged on the top of the box body 3, and the box body 3 One side of the cover 4 is hingedly connected to one side of the box body 3 through a hinge 9, the power switch 6 and the touch display screen 5 are fixedly installed on the top of the box cover 4, and the transparent without The colored glass plate 10 is fixedly installed on the upper part of the installation through groo...

Embodiment 2

[0083] The difference from Example 1 is further that a protective layer is also provided on the surface of the transparent colorless glass plate 10, and the protective layer is prepared by the following method:

[0084] Take the following raw materials and weigh them by weight: 10 parts of polyvinyl alcohol, 4 parts of melamine resin, 3 parts of acrylic acid, 5 parts of methacrylic acid, 6 parts of glutaraldehyde, 2 parts of ammonium persulfate, 8 parts of isopropanol, polyethylene 6 parts of diol, 3 parts of n-butanol, 2 parts of glycerin and 18 parts of purified water;

[0085] S1. Add the weighed polyvinyl alcohol, melamine resin, acrylic acid, methacrylic acid, glutaraldehyde, ammonium persulfate, isopropanol, polyethylene glycol, n-butanol, glycerin and purified water into the beaker;

[0086] S2. Place the beaker with the materials added in step 2 on the shelf above the alcohol lamp, and use the alcohol lamp to heat the beaker for 6 minutes, during which the glass rod is...

Embodiment 3

[0092] The difference with embodiment 2 is the preparation of protective layer, and its specific preparation method is as follows:

[0093] Take the following raw materials and weigh them by weight: 12 parts of polyvinyl alcohol, 5 parts of melamine resin, 4 parts of acrylic acid, 6 parts of methacrylic acid, 7 parts of glutaraldehyde, 3 parts of ammonium persulfate, 9 parts of isopropanol, polyethylene glycol 7 parts of diol, 4 parts of n-butanol, 3 parts of glycerin and 21 parts of purified water;

[0094] S1. Add the weighed polyvinyl alcohol, melamine resin, acrylic acid, methacrylic acid, glutaraldehyde, ammonium persulfate, isopropanol, polyethylene glycol, n-butanol, glycerin and purified water into the beaker;

[0095] S2. Place the beaker with the materials added in step 2 on the shelf above the alcohol lamp, and heat the beaker with the alcohol lamp for 7 minutes, during which the glass rod is continuously used to stir clockwise;

[0096] S3, cooling the mixed solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com