Neutral detergent for optical plating

A neutral cleaning agent, optical coating technology, applied in the directions of surface active detergent composition, detergent compounding agent, detergent composition, etc., can solve problems such as difficulty in achieving gloss, achieve low cost, obvious progress, Practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

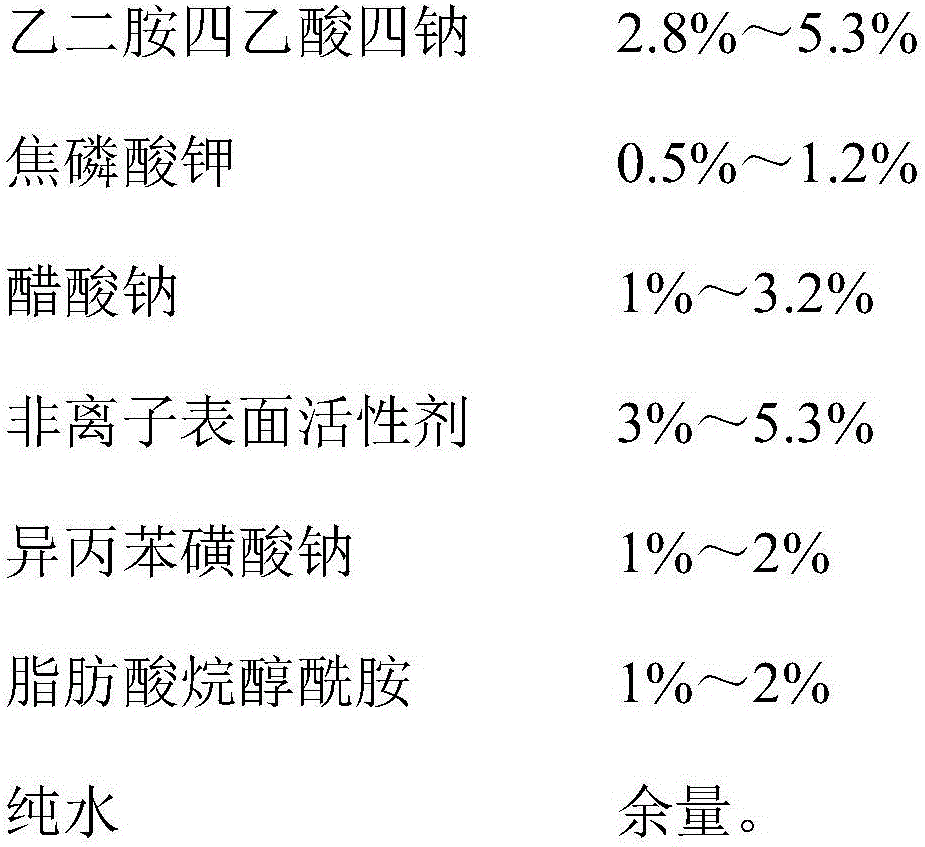

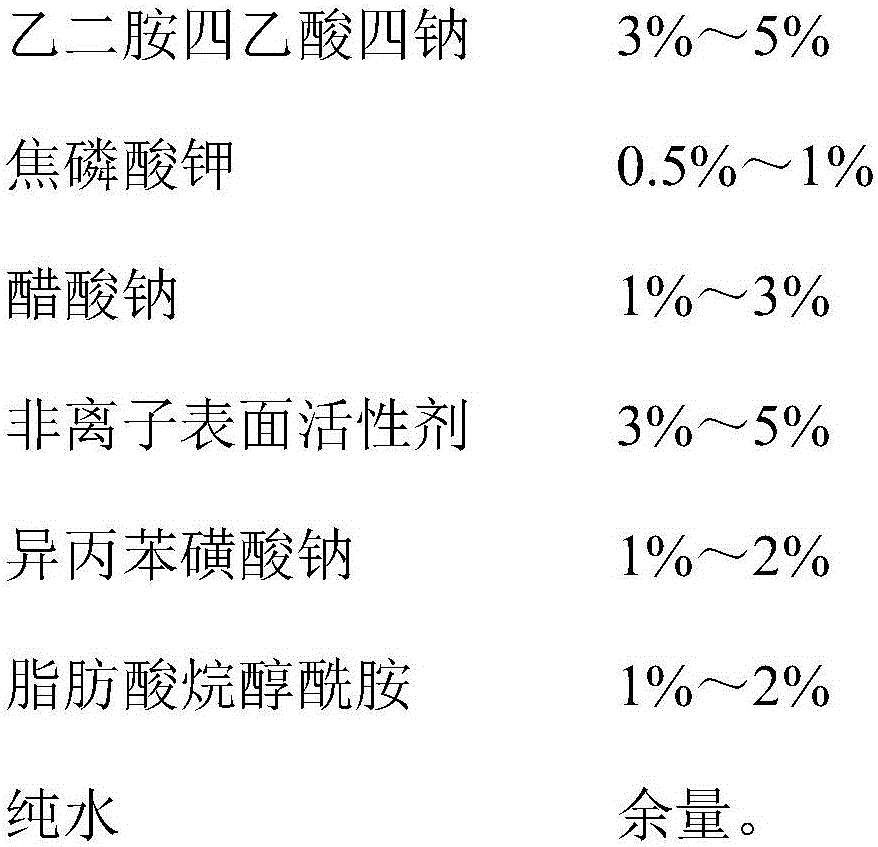

Method used

Image

Examples

Embodiment 1

[0021] Weigh 2.8 kg of tetrasodium edetate, 1.2 kg of potassium pyrophosphate, 3.2 kg of sodium acetate, 3 kg of nonionic surfactant, 1 kg of sodium cumene sulfonate, 1.5 kg of fatty acid alkanolamide, and 87.3 kg of pure water. In the container, stir evenly to obtain a neutral detergent.

[0022] Tetrasodium ethylenediaminetetraacetic acid (ETDA4Na) mainly plays a role in water softness and complexation.

[0023] In practical application, it is necessary to mix and dilute the neutral cleaning agent of the present invention with water at a ratio of 1:20, and the effect of potassium pyrophosphate can also produce the effect of dispersing oil stains without certain alkalinity. It has a good effect on removing white spots on the optics, and can also play a role in buffering, emulsifying, and integrating. Pyrophosphate ions have a good dispersing effect on dotted coating.

[0024] In this example, the compounded nonionic surfactant is a low-foaming ethoxy-propoxyl C8-C10 fatty a...

Embodiment 2

[0029] Weigh 3.5kg of tetrasodium edetate, 1kg of potassium pyrophosphate, 1.5kg of sodium acetate, 4kg of nonionic surfactant, 1.5kg of sodium cumene sulfonate, 1kg of fatty acid alkanolamide, and 87.5kg of pure water in In the container, stir evenly to obtain a neutral detergent. It is very well mixed in the synthesis of the overall formula ingredients, without turbidity and precipitation. The pH value of this neutral cleaning agent is 8.0, the cost of compatibility is low, and it can completely replace the high price of imported products. Now the field of optical coating is more and more extensive, and it is favored by the majority of processing and manufacturing enterprises. The progress is obvious and the practicability powerful.

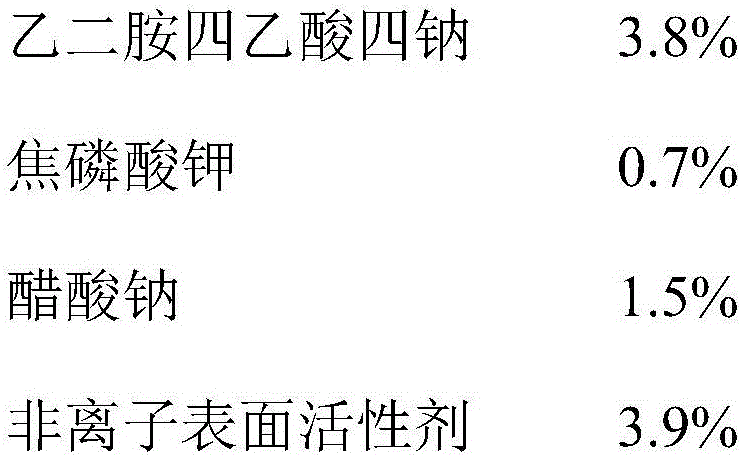

Embodiment 3

[0031] Weigh 4kg of tetrasodium edetate, 0.8kg of potassium pyrophosphate, 2kg of sodium acetate, 4kg of nonionic surfactant, 1.5kg of sodium cumene sulfonate, 1.5kg of fatty acid alkanolamide, and 86.2kg of pure water in In the container, stir evenly to obtain a neutral detergent. It is very well mixed in the synthesis of the overall formula ingredients, without turbidity and precipitation. The pH value of the neutral cleaning agent is 8.2, the cost of compatibility is low, and it can completely replace the high price of imported products. Now the field of optical coating is more and more extensive, and it is favored by the majority of processing and manufacturing enterprises. The progress is obvious and the practicability stronger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com