Self-assembly porphyrin nano fiber material and manufacturing and application thereof

A technology of nanofibers and fibrous materials, applied in the field of self-assembled nanofiber materials, can solve problems such as quenching of nonlinear optical response of materials, and achieve the effects of good product morphology, low reaction temperature, and simple and easy-to-control operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

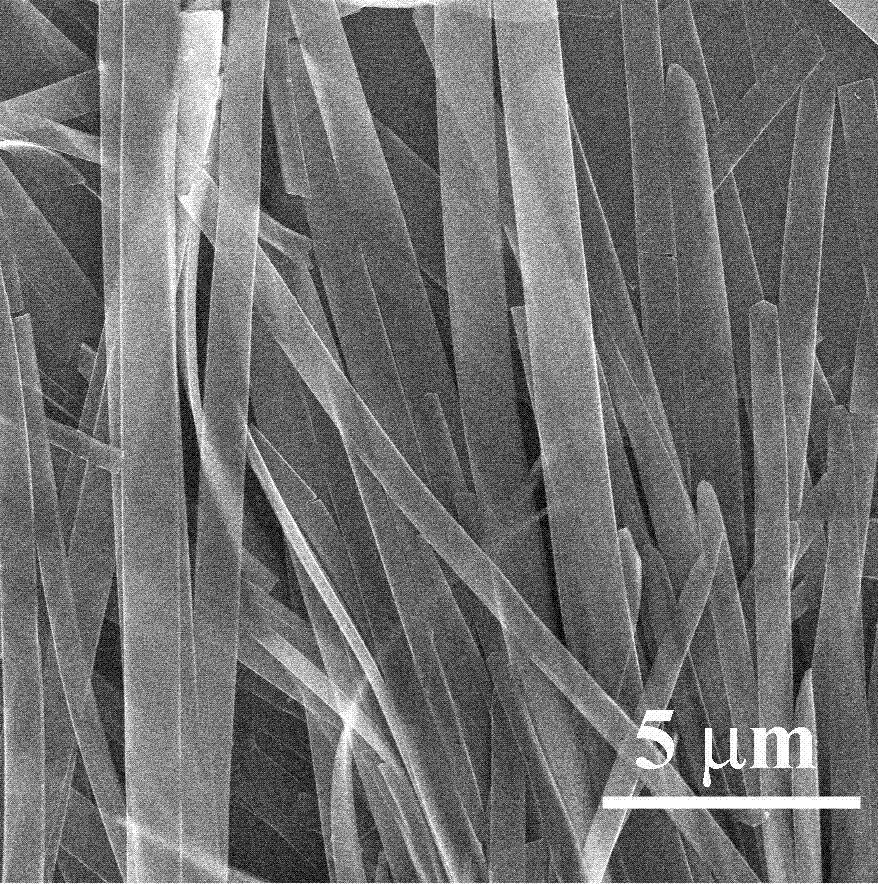

[0030] Embodiment 1: the preparation of self-assembled nanofiber material

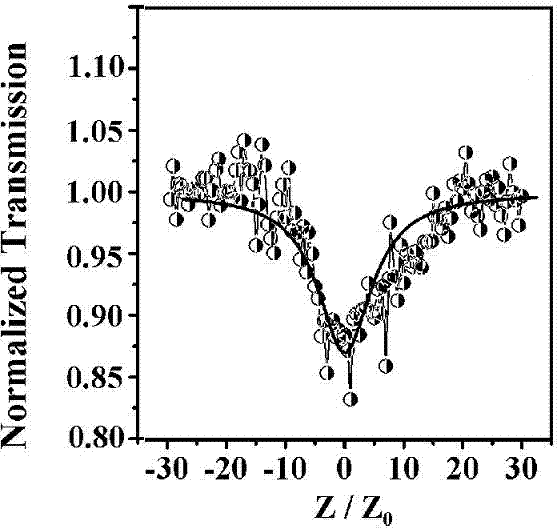

[0031] Add 5,15-ferrocenyl zinc porphyrin (0.1122 g, 0.15 mmol) and 4,4'-bipyridine (0.1171 g, 0.75 mmol) into 60 mL of chloroform solution and stir to dissolve, then slowly add methanol solution 300mL, placed in a flask, sealed, and left to stand for 60 h. The resulting product was washed with methanol, centrifuged and dried at 60°C in vacuum for 6 h to obtain 0.1390 g of self-assembled porphyrin nanofiber material. The scanning electron micrograph of the obtained self-assembled porphyrin nanofiber material is as follows: figure 1 Shown; The XRD pattern of self-assembled porphyrin nanofiber material is as image 3 shown.

Embodiment 2

[0032]Embodiment 2: the preparation of self-assembled nanofiber material

[0033] Add 0.1122 g of 5,15-ferrocenyl zinc porphyrin and 0.2341 g of 4,4'-bipyridine into 90 mL of chloroform solution and stir to dissolve, then slowly add 300 mL of methanol solution, place it in a flask, seal it, and let it stand After 72 h, the obtained product was washed with methanol, centrifuged and dried under vacuum at 60°C for 6 h to obtain 0.1305 g of self-assembled porphyrin nanofiber material. Scanning electron micrographs of the self-assembled porphyrin nanofibers figure 1 Basically the same, its XRD spectrum and image 3 Basically the same.

Embodiment 3

[0034] Embodiment 3: the preparation of self-assembled nanofiber material

[0035] Add 0.1122 g of 5,15-ferrocenyl zinc porphyrin and 0.4684 g of 4,4'-bipyridine into 30 mL of chloroform solution and stir to dissolve, then slowly add 450 mL of methanol solution, place it in a flask and seal it, and let it stand After 30 h, the obtained product was washed with methanol, centrifuged and dried under vacuum at 60° C. for 6 h to obtain 0.1321 g of self-assembled porphyrin nanofiber material. Scanning electron micrographs of the self-assembled porphyrin nanofibers figure 1 Basically the same, its XRD spectrum and image 3 Basically the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com