Touch panel and manufacturing method thereof

A touch panel and substrate technology, which is applied to instruments, electrical digital data processing, and input/output processes of data processing, etc. The effect of improving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

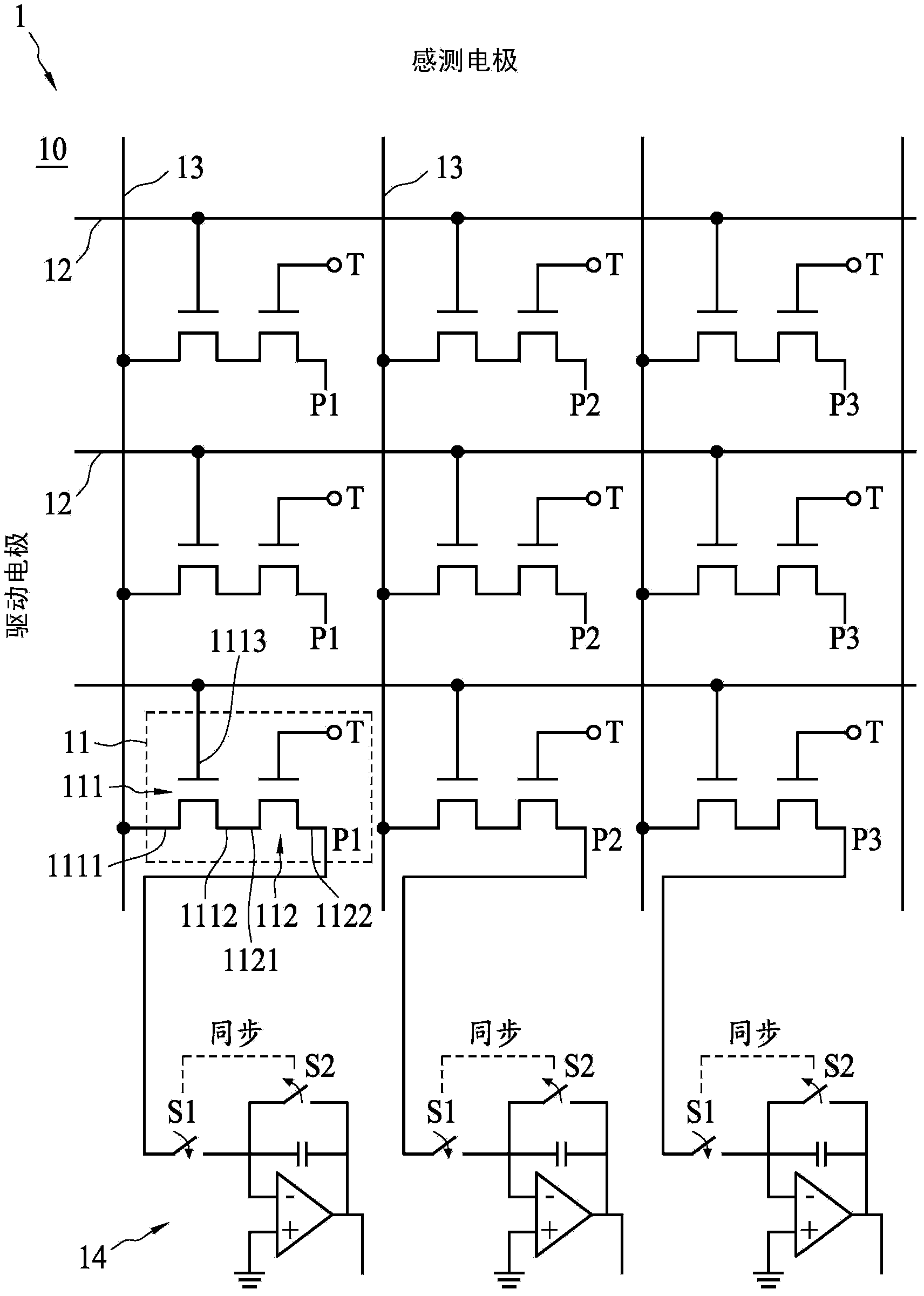

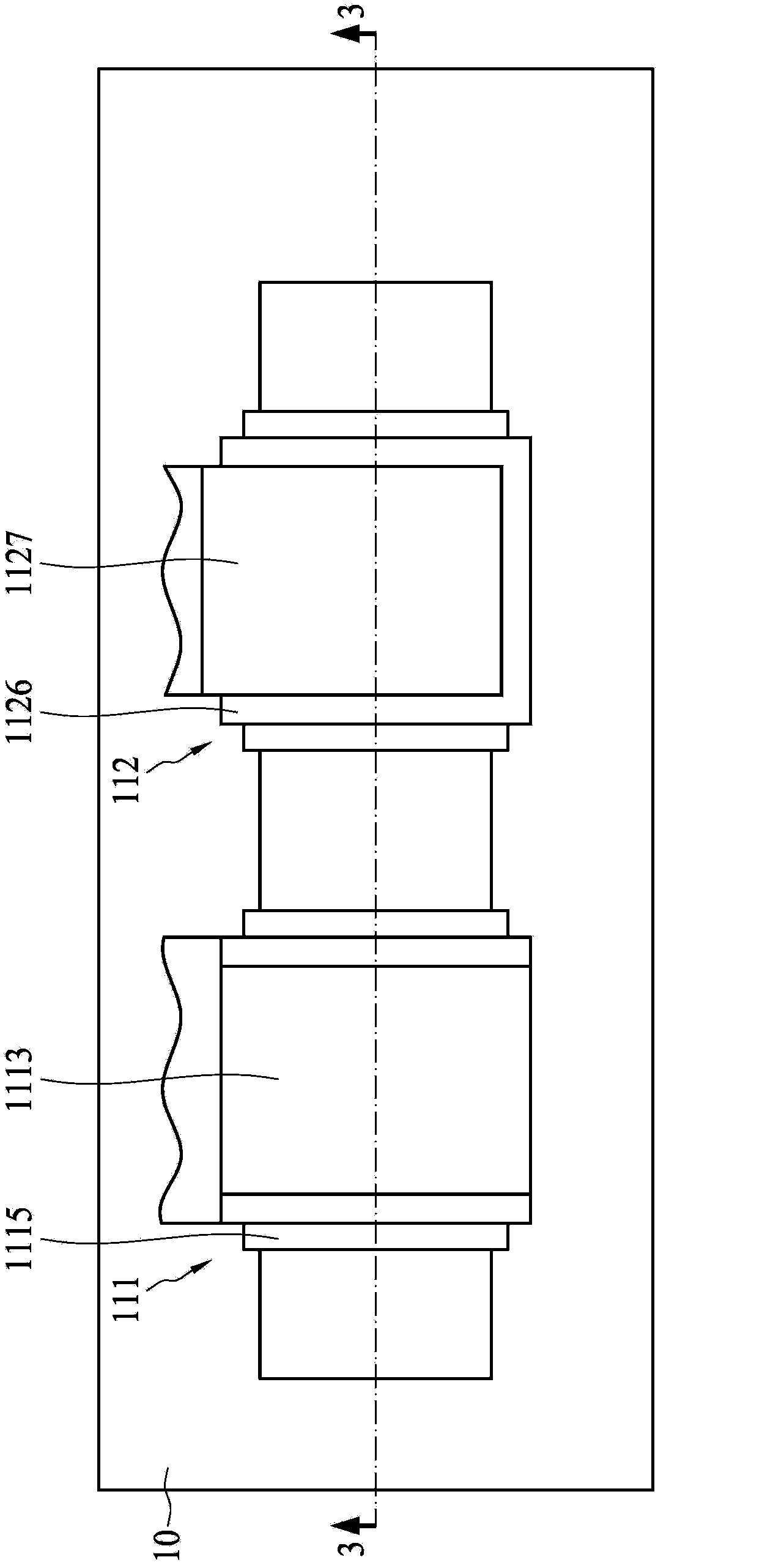

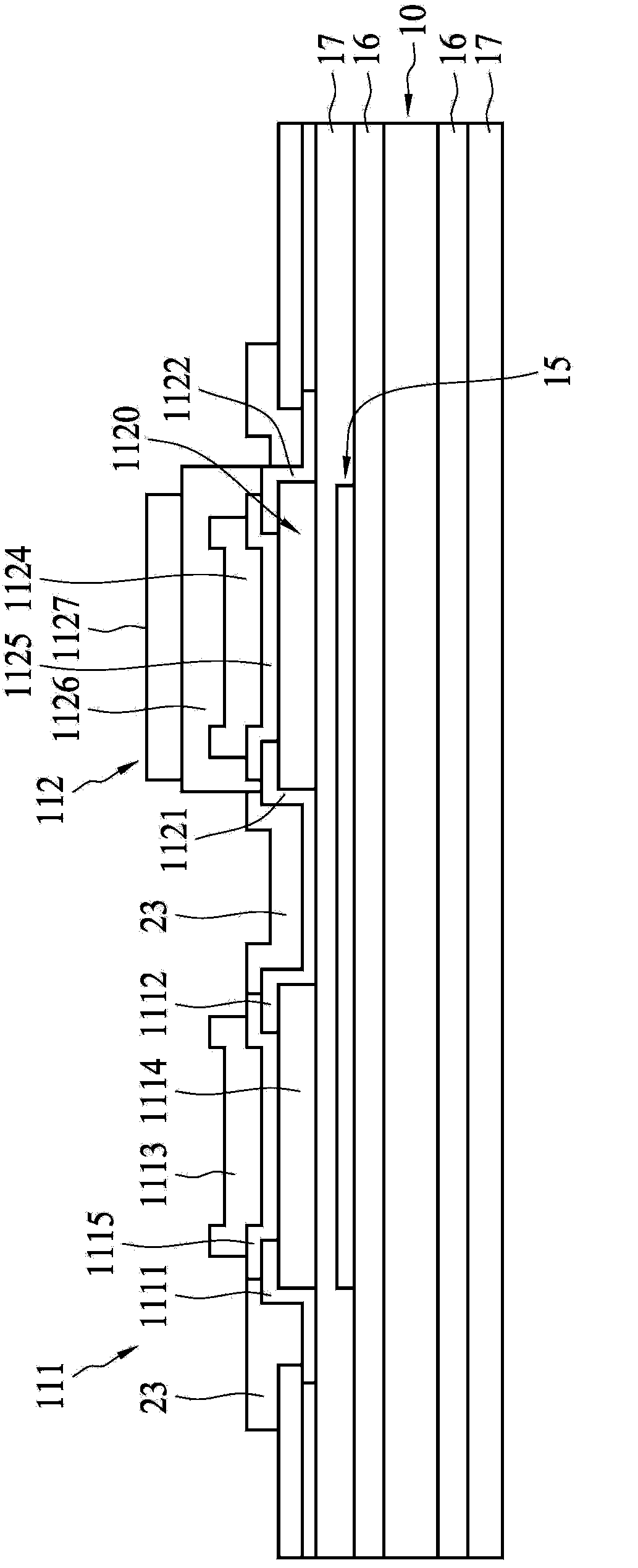

[0055] figure 1 It is a schematic diagram of a touch panel 1 according to an embodiment of the present invention. refer to figure 1 As shown, the touch panel 1 includes a plurality of sensing units 11 arranged in an array. A plurality of sensing units 11 can be (but not limited to) arranged in an array on a substrate 10 . A plurality of arrayed drive electrodes (Drive Electrode) 12 and a plurality of arrayed sensing electrodes (Sense Electrode) 13 are formed on the substrate 10, and a plurality of sensing units 11 are individually separated, and each sensing unit 11 is combined with a phase An adjacent driving electrode 12 is connected to an adjacent sensing electrode 13 . The sensing unit 11 is used for sensing the touched position of the panel, or a single area, or multiple areas. The driving electrodes 12 and the sensing electrodes 13 can be transparent conductors (such as indium tin oxide (ITO) to make the substrate 10 transparent), and these two groups of electrodes 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com