Sphere conveying mechanism of device for machining high-precision sphere

A technology of conveying mechanism and processing equipment, which is applied in the direction of metal processing equipment, grinding machine tools, working carriers, etc., can solve the problems of poor accuracy of processing path control, no ball circulation processing function, and poor processing consistency, so as to achieve convenient observation inspection and guarantee The effect of grinding quality, consistent batch processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

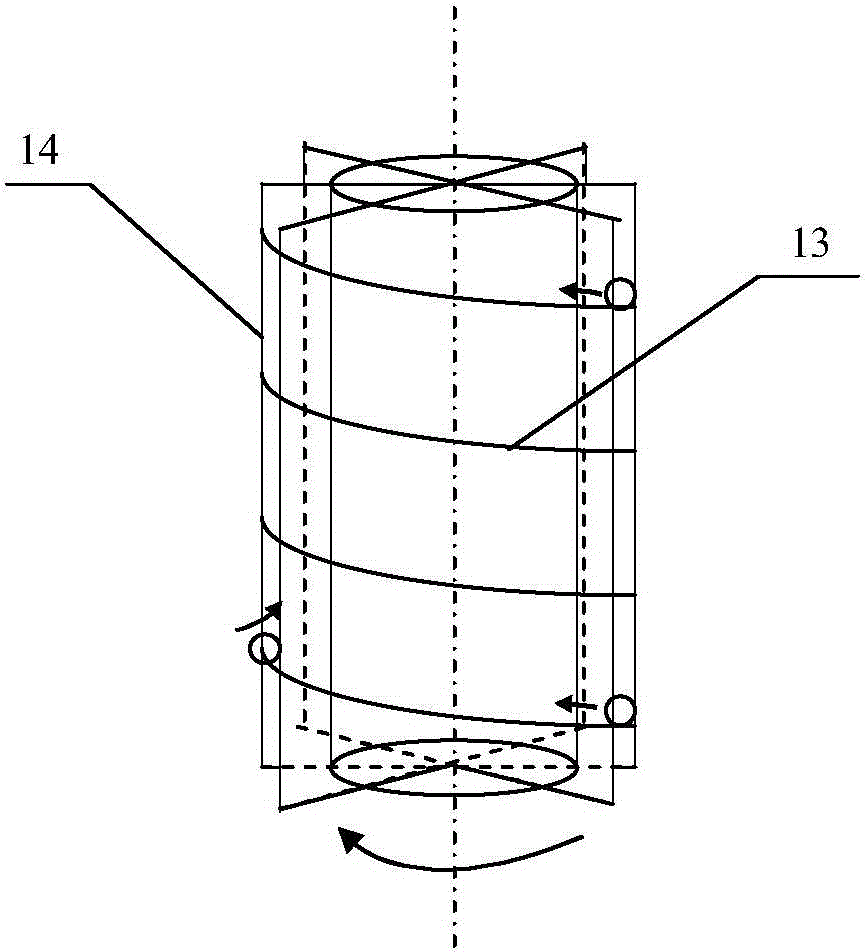

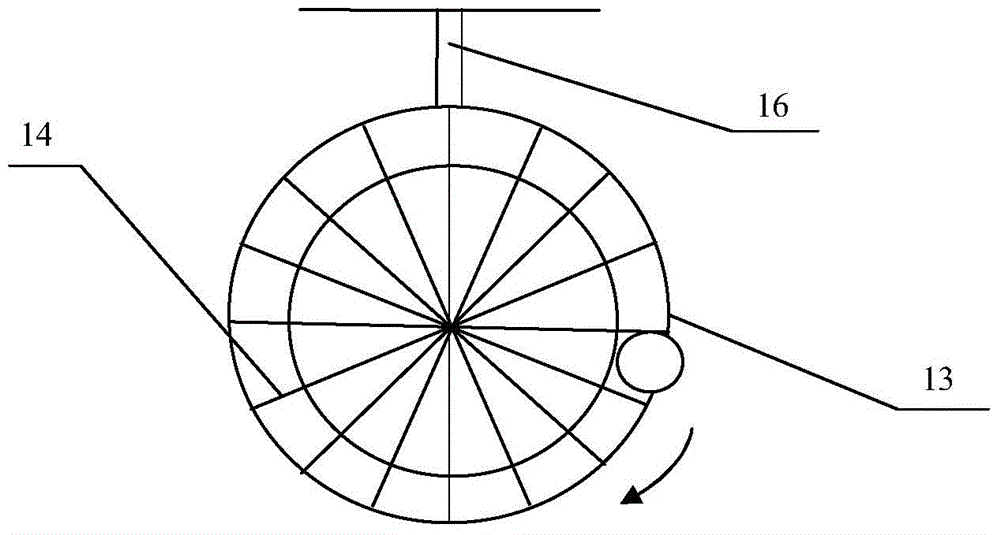

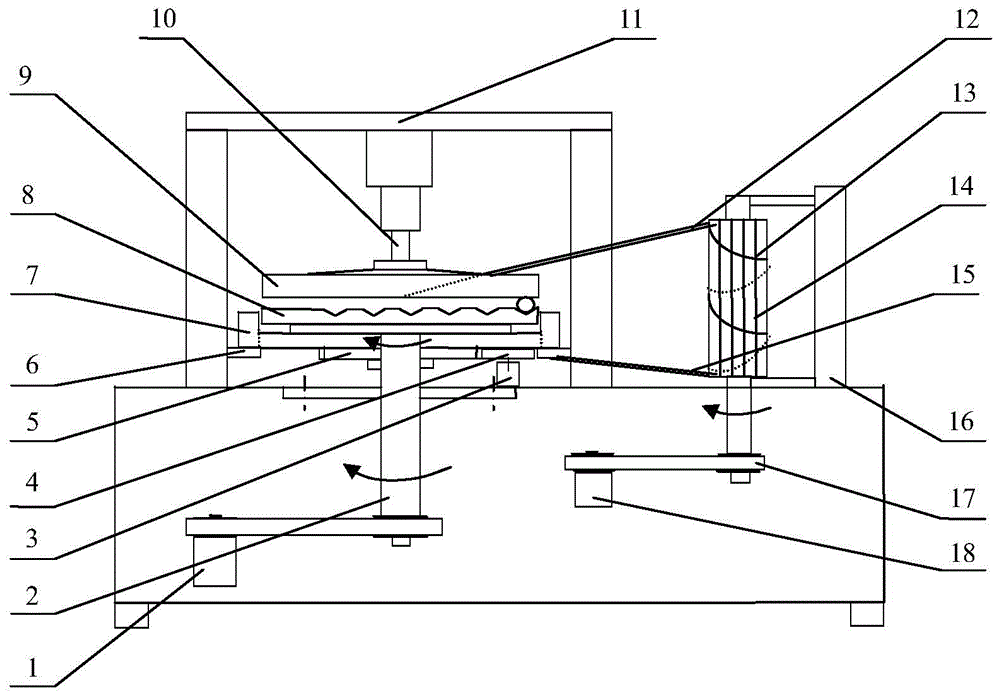

[0018] refer to Figure 1 to Figure 5 , a ball conveying mechanism of high-precision ball processing equipment, including a bracket 16, an upper free raceway 12, a lower free raceway 15, an outer spiral raceway 13, a mandrel and a scraper 14, the upper free raceway 12, The lower free raceway 15 and the outer spiral raceway 13 are installed on the bracket 16, the mandrel is connected with the feeding drive mechanism for driving the mandrel to rotate, and the scrapers are arranged at intervals of circular arcs such as the outer ring of the mandrel. plate 14, the gap between the adjacent scrapers 14 is larger than the ball to be conveyed, the outer spiral raceway 13 is arranged from top to bottom, the outer spiral raceway 13 is attached to the outer surface of the scraper 14, the The gap between adjacent scrapers 14 and the outer spiral raceway 13 form a conveying statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com