Metal microorganism corrosion electrochemical testing device under flowing system

A technology of microbial corrosion and testing equipment, which is applied in the direction of measuring equipment, weather resistance/light resistance/corrosion resistance, scientific instruments, etc., can solve the problems of unable to gather and grow metal materials, etc., so as to facilitate sampling and detection, reduce disturbance, and facilitate repetition The effect of corrosion monitoring experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

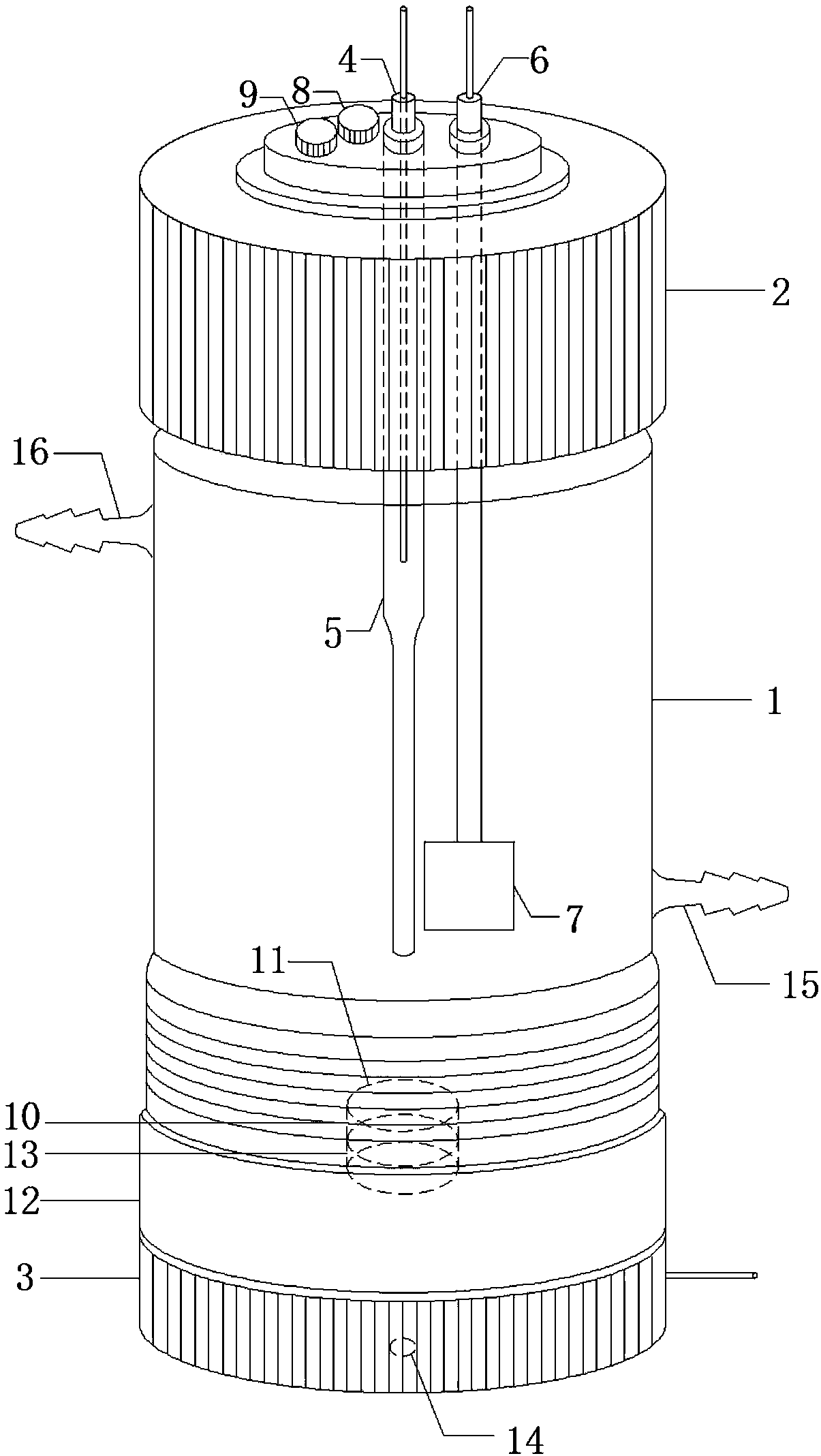

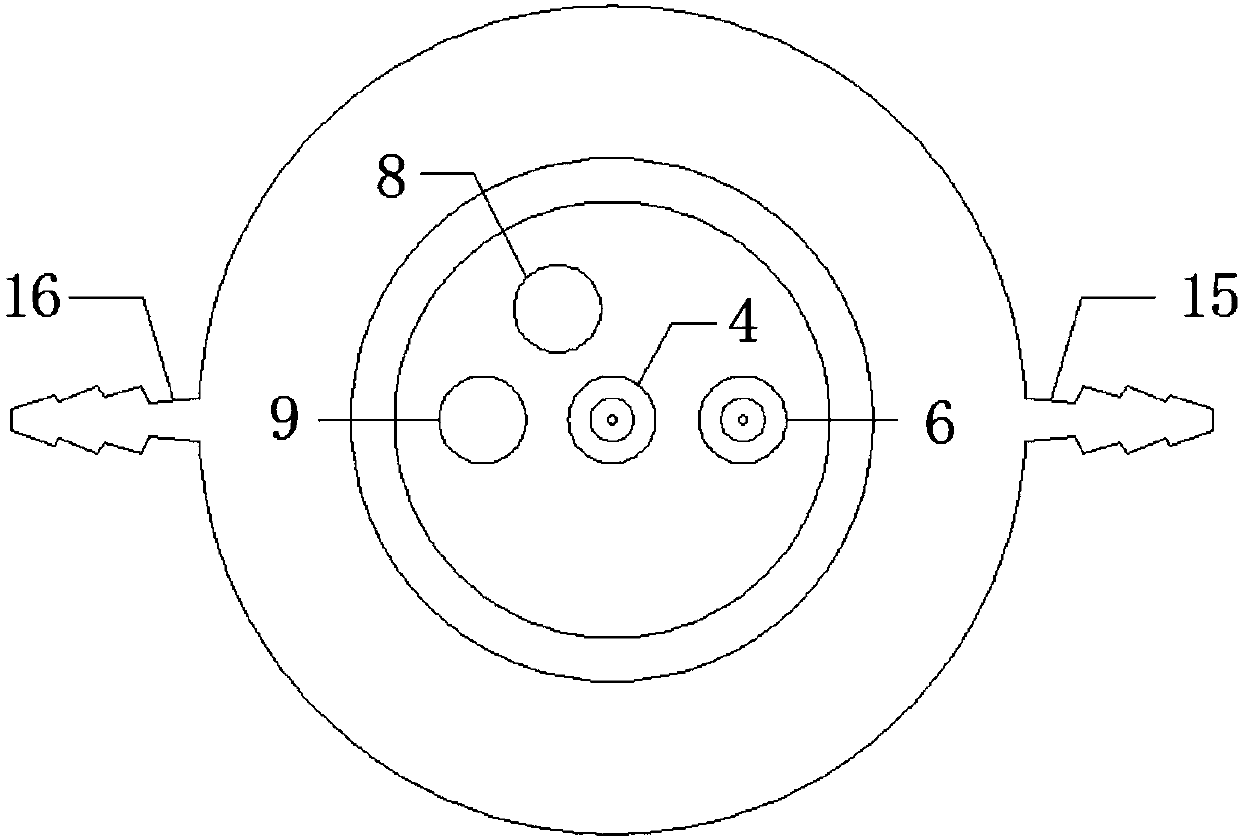

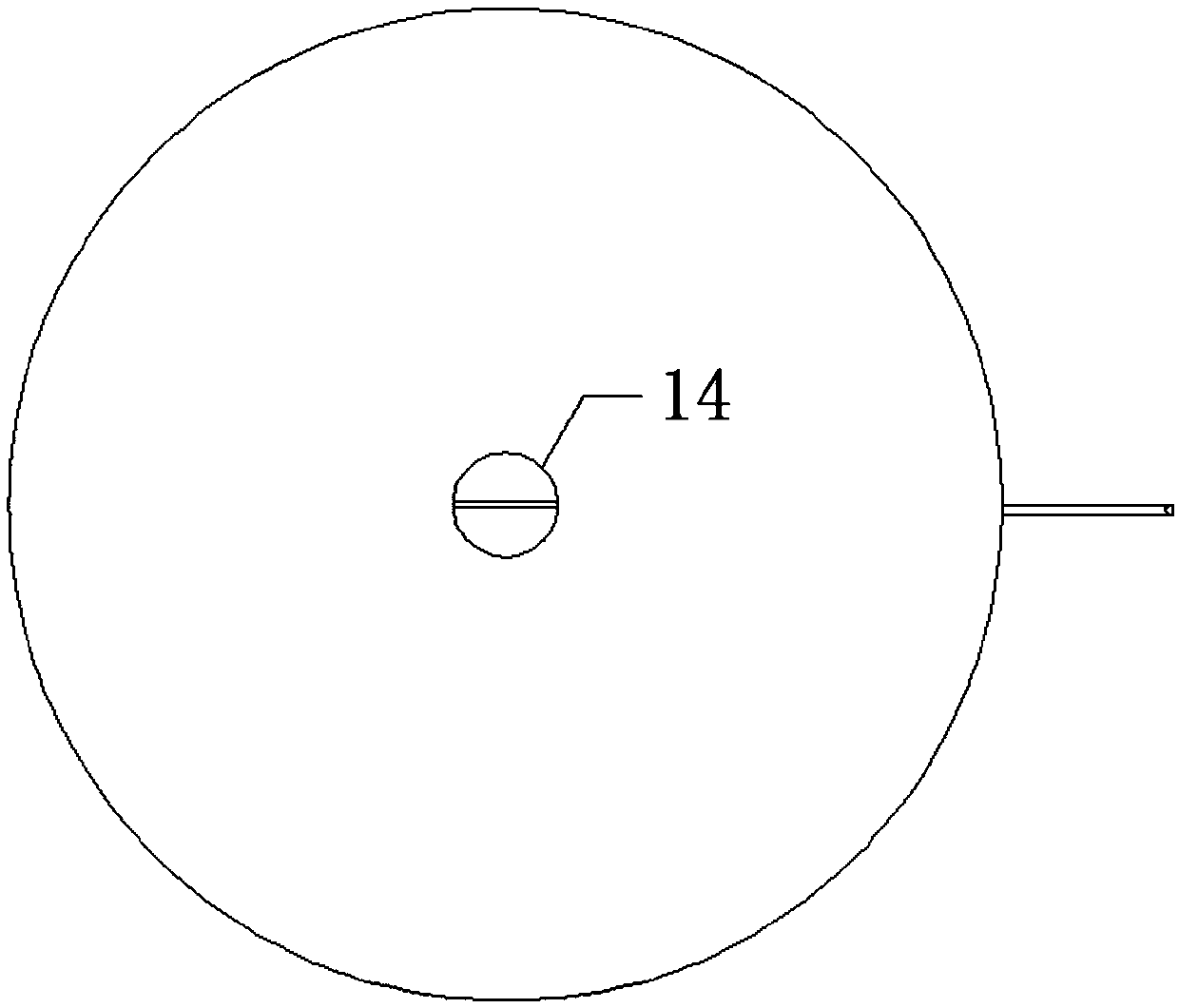

[0045] This example studies the corrosion mechanism of reclaimed water pipelines under the coupled action of disinfectants and microorganisms. After the raw water was sterilized at high temperature, 10 mL of sulfate-reducing bacteria liquid (about 5×10 9 ), respectively adding 0mg / L, 3mg / L, 6mg / L and 9mg / L sodium hypochlorite for corrosion experiment, each experiment period is 15 days. During the test, input the basic parameters such as nodular cast iron metal material characteristics and experimental conditions in the electrochemical workstation; after the open circuit potential is stable, select the measurement method as polarization curve measurement, select the reference electrode as the saturated Ag / AgCl reference electrode, and set The potential interval is 0.5mV, the initial potential is -0.1V relative to the open circuit potential, the end potential is 0.1V relative to the open circuit potential, and the scanning speed is 0.5mV / s. The results of the potentiodynamic sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com