Aluminum foil thermo-printing machine

A hot stamping machine and aluminum foil technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of uncontrollable quality, lack of detection devices, and unqualified products, so as to prevent the production of unqualified products, control product quality, Realize the effect of traceable plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

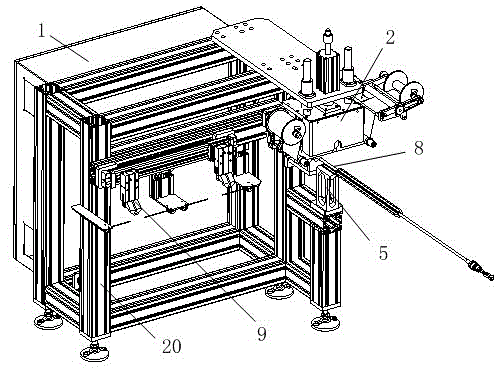

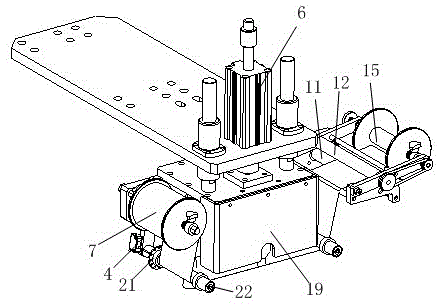

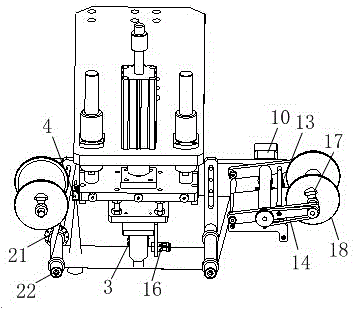

[0044] Such as Figures 1 to 3 As shown, an aluminum foil hot stamping machine of the present invention includes a control cabinet 1 arranged on a frame 20 , a hot stamping assembly 2 and a lower die set 5 supporting a product 8 . The hot stamping assembly 2 is located above the lower die set 5, and the hot stamping assembly 2 includes: a font 3, a paper feed sensor 4, a pressing cylinder 6, a ribbon 7, a stepping motor 10, a drive wheel 11, a retractor Paper cylinder 15, type model sensor 16, paper feed wheel 21, and tension wheel 22. The font 3 is arranged below the press-down cylinder 6, the ribbon 7 and the paper delivery tube 15 are respectively located on both sides of the press-down cylinder 6, and the ribbon 7 passes through the press-down cylinder 6 through several tension wheels 22. The lower part of the font 3 reaches the paper delivery cylinder 15, the tension wheel 22 is provided with the paper feed wheel 21, the paper feed sensor 4 detects whether the paper feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com