Precise positioning device for fast tunneling equipment in coal mine coal mining tunnel

A precise positioning and roadway technology, applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve problems that affect coal mine production efficiency and safety production, rapid excavation equipment collision and falling off, short visual distance, etc., and is easy to promote , Prevent collision and fall-off accidents, the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

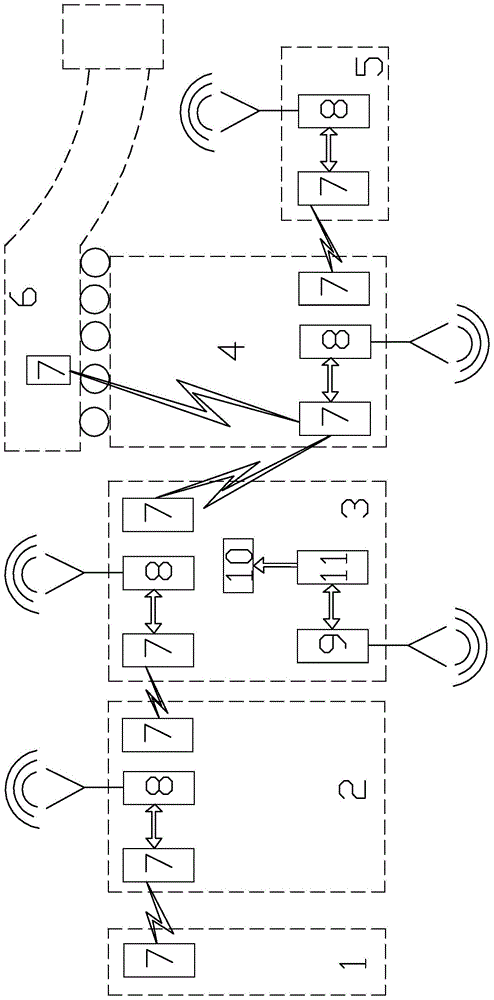

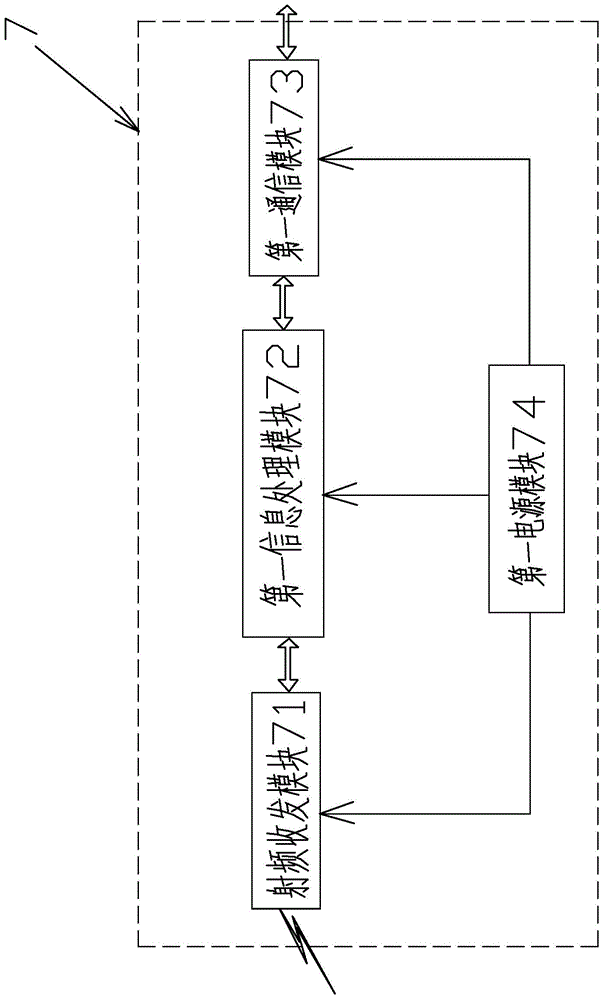

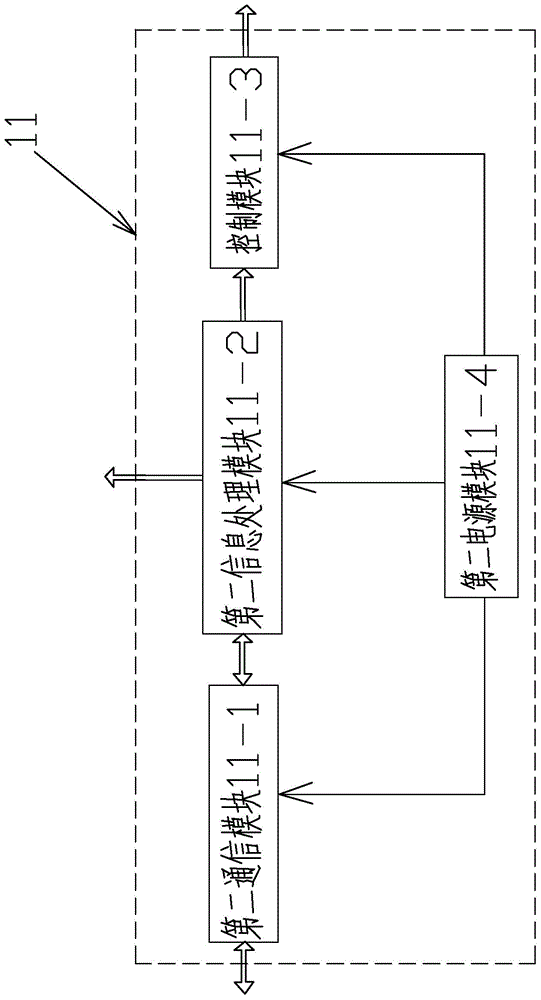

[0019] See figure 1 , the precise positioning device for rapid excavation equipment in the coal mining roadway of the coal mine in this embodiment is mainly composed of a roadheader 1, a crusher 2, a bolter rig 3, a stepping self-moving tail 4, a self-moving power station 5, and a tape transfer machine 6. It consists of a node locator 7, a wireless conversion gateway 8, a wireless base station 9, a positioning display 10 and a positioning controller 11.

[0020] There are nine node locators 7 in total, and the nine node locators 7 have the same structure. The nine node locators 7 are respectively provided with one on the roadheader 1, two on the crusher 2, two on the bolter 3, and two on the tail 4 of the walking self-moving machine. One is installed on the station 5 and one is installed on the tape transfer machine 6 .

[0021] There are 4 wireless switching gateways 8 in total, and one of the 4 wireless switching gateways 8 is respectively set on the crusher 2 , the rock b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com