A Large Horizontal Biomass Diversified Raw Material Burner

A biomass and burner technology, applied in the direction of solid fuel combustion, combustion methods, combustion equipment, etc., can solve the problems of large horizontal space, waste of manpower, material resources, financial resources, inconvenient use, etc., and achieve small horizontal space occupation and shrinkage Lateral distance, reducing the effect of the docking procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

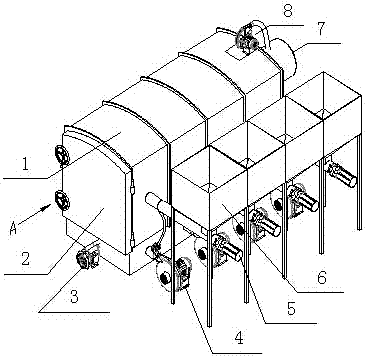

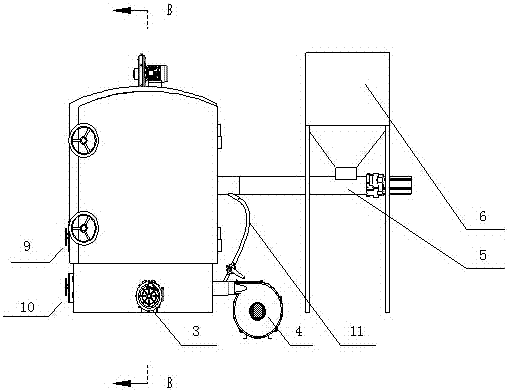

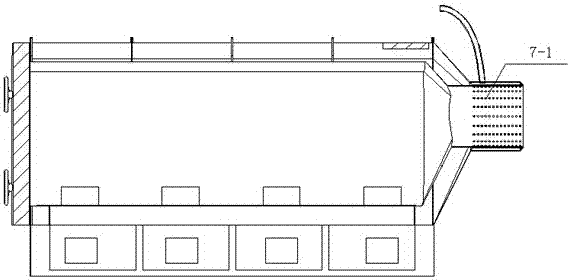

[0023] like figure 1 As shown, the large-scale horizontal biomass multiple raw material combustion machine of the present invention includes a feeder 6, a feeder 5 connected to the discharge port below the feeder 6, and a combustion chamber 1 connected to the discharge end of the feeder 5, which is arranged in The igniter 3 at the bottom of the combustion chamber 1, the oxygen supply blower 4 and the flame nozzle 7 arranged on the combustion chamber 1; In the chamber 1, the fire grate is used as the horizontal dividing line, the upper combustion part is connected as a whole, and the lower part is divided into a plurality of air inlet chambers, and each air inlet chamber is connected with an oxygen supply fan 4 respectively.

[0024] First connect the flame vent 7 with the heat-requiring equipment, then put the biomass fuel into the silo 6, send it into the combustion chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com