Semiconductor device, transparent metal mesh electrode, and preparation method of transparent metal mesh electrode

A technology of mesh electrodes and manufacturing methods, which is applied to semiconductor devices, circuits, electrical components, etc., and can solve the problems of unsatisfactory optical performance of nanometer metal grid wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] Example 1, using a transparent metal mesh electrode instead of the traditional annealed ITO transparent electrode layer to form an ohmic contact in a front-mount LED structure, including steps:

[0034] Step 1: Clean the LED epitaxial wafer;

[0035] Step 2: Lay PS balls on the LED epitaxial wafer p-GaN structure by pulling method;

[0036] Step 3: Shrunk the ball using plasma etching method;

[0037] Step 4: Evaporate 10nm thick metal Pt;

[0038] Step 5: Clean and remove the PS balls to obtain a transparent metal Pt mesh electrode to form an ohmic contact with p-GaN;

[0039] Step 6: Carry out follow-up processes such as photolithography mesa, metal mesh electrode corrosion, and ICP mesa etching.

example 2

[0040] Example 2, see Figure 1 to Figure 5 , including the following steps:

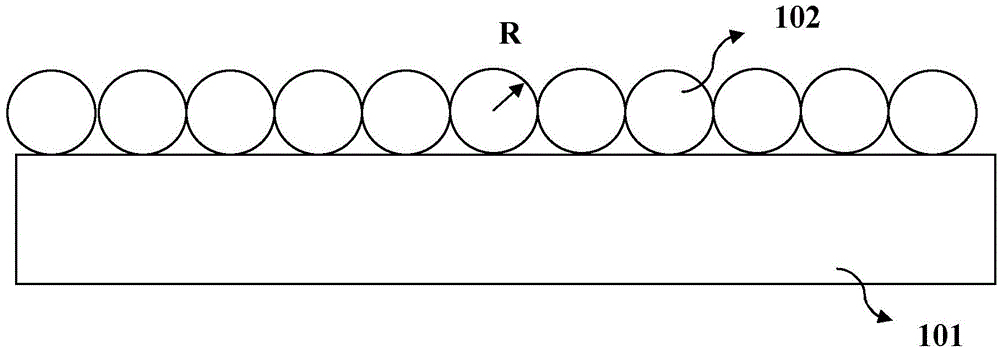

[0041] Step 1: Select a cleaned sapphire substrate, and use the pulling method to lay a single layer of PS balls with a diameter of about 900nm on the surface;

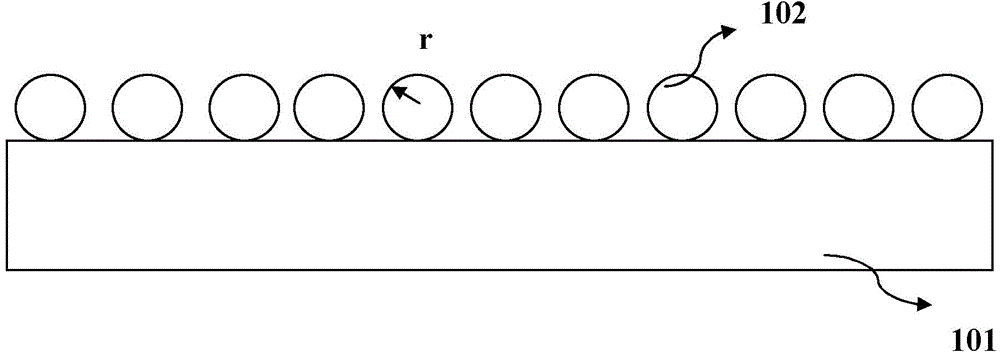

[0042] Step 2: Use plasma etching method to shrink the ball, and reduce the diameter of the PS ball to about 870nm;

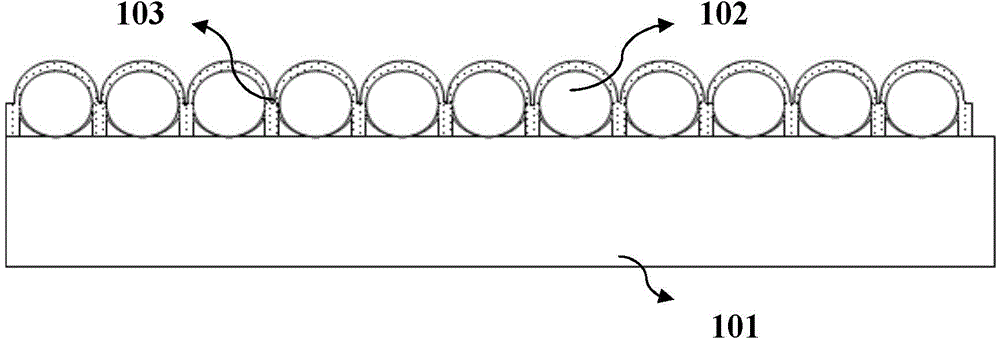

[0043] Step 3: using a vacuum evaporation method to evaporate a 30nm thick Ni metal layer on the substrate after shrinking the ball;

[0044] Step 4: cleaning the substrate after metal evaporation, removing the PS ball and the metal film covering it, and obtaining a transparent metal Ni mesh film electrode layer with a slight metallic luster.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com