Plasma-mig welding method and welding torch

A welding method and plasma welding technology, applied in the directions of plasma welding equipment, plasma, welding equipment, etc., can solve the problem of reducing the amount of spatter, and achieve the effect of reducing the amount of spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

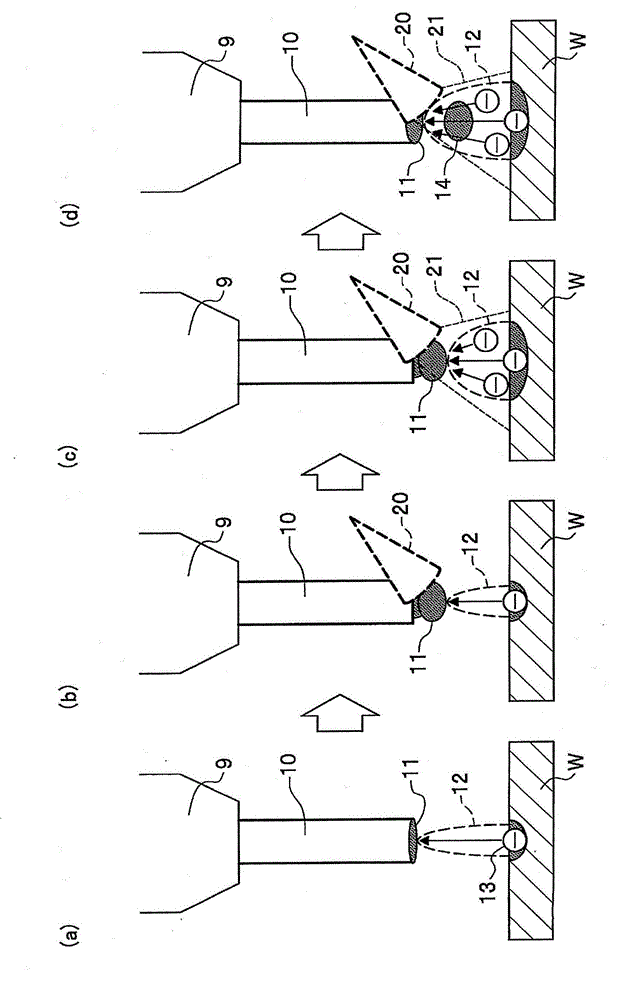

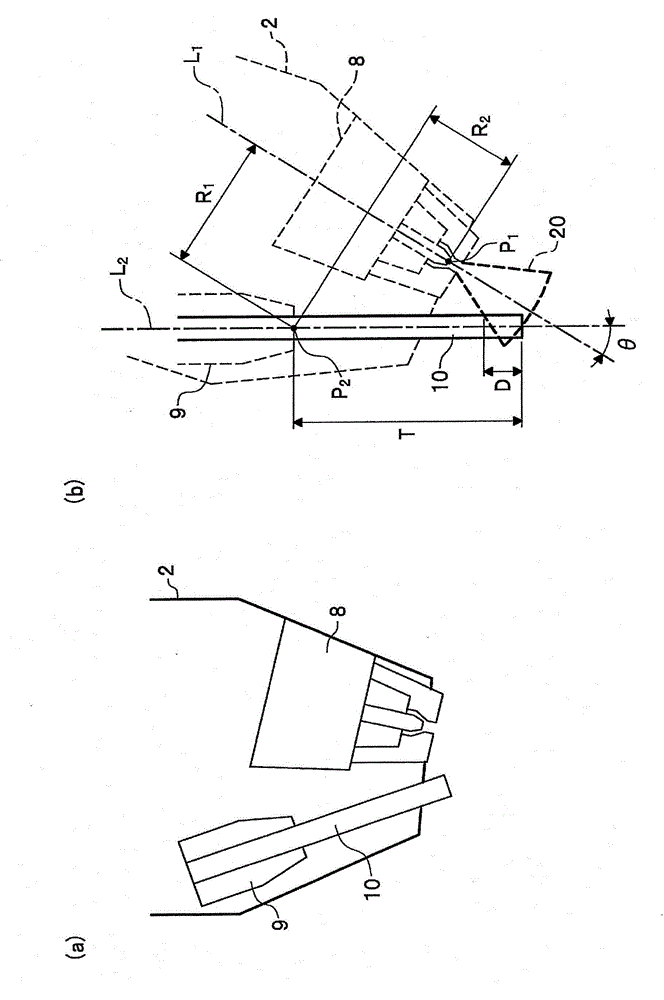

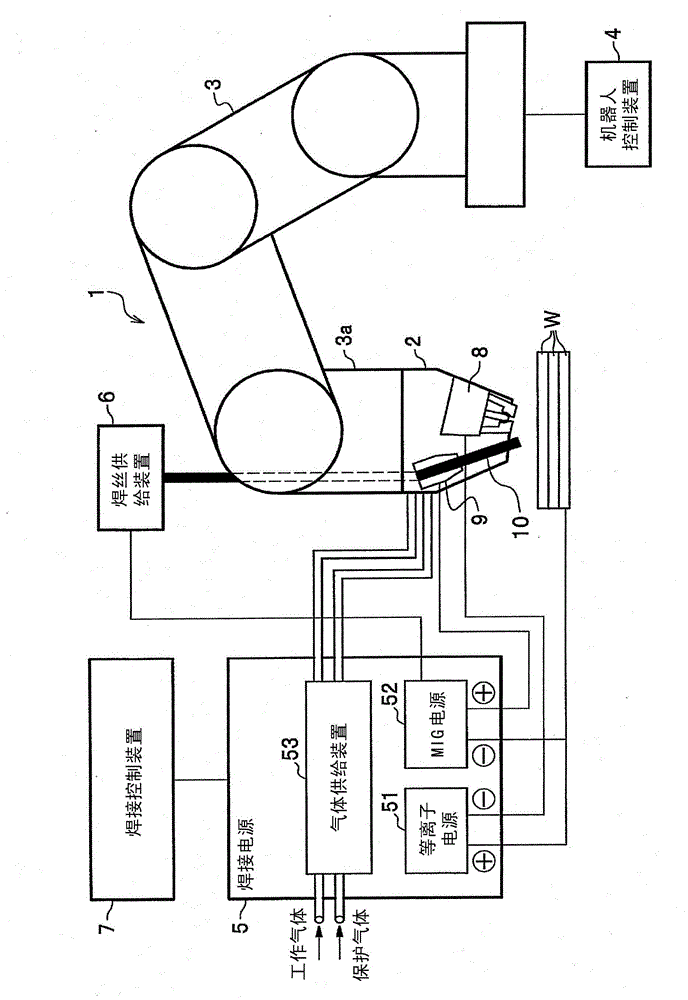

[0082]As the effect of the plasma-MIG welding method of the present invention, by using plasma to heat the MIG welding wire, the droplet can be dispersed in the air without short-circuit transfer, and the droplet transfer can be carried out. In order to confirm this effect, the plasma welding The torch part 8 and the MIG welding torch 9 were arranged at a predetermined distance apart from each other in different directions, and the following experiments 1 and 2 were performed.

[0083] The conditions common to each experiment are as follows. The MIG welding current (also referred to simply as MIG current) was a constant value (150A). The diameter of the welding wire is 1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com