Oil cooling and oil mist purifying filtering equipment of numerical control boring tapping center machine tool

A filtration equipment and oil cooling technology, applied in filtration and separation, metal processing equipment, fixed filter element filters, etc., can solve the problems of little filtration effect, environmental impact, corruption, etc., to improve filtration efficiency and accuracy, and increase production capacity , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution in the embodiment will be specifically, clearly and completely described below in conjunction with the drawings in the embodiment.

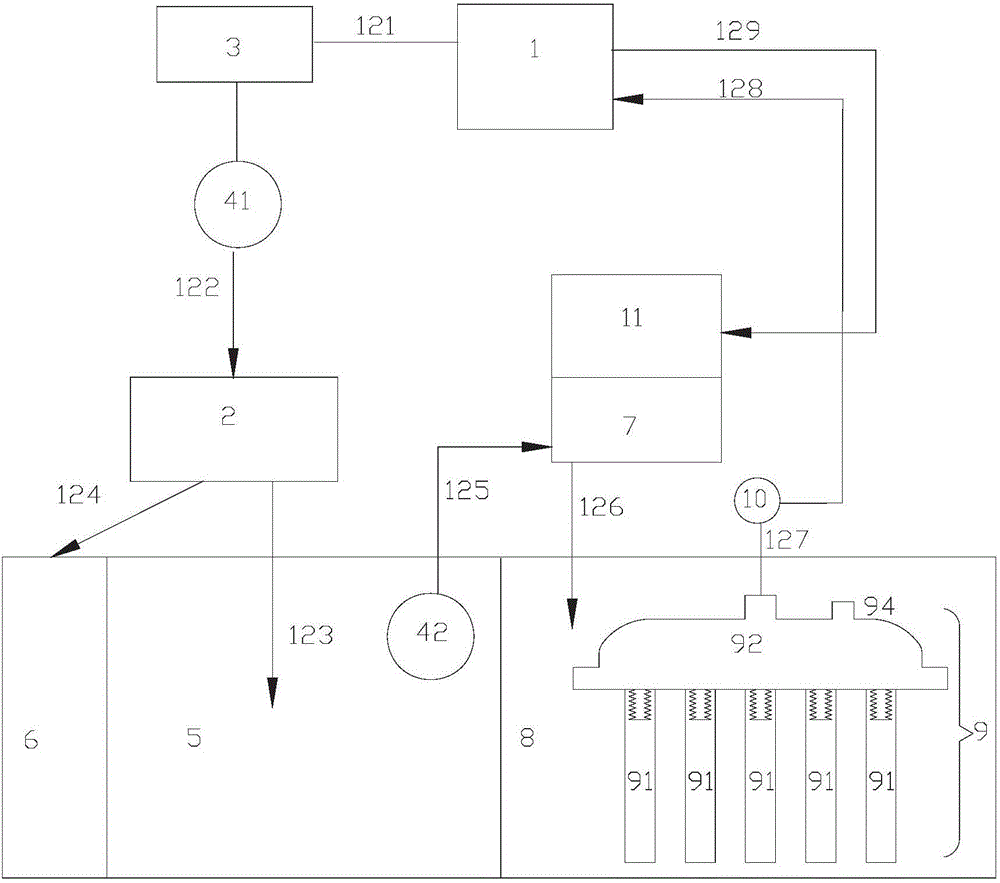

[0034] A CNC drilling and tapping center machine tool oil cooling oil mist purification and filtration equipment, including the following components integrated:

[0035] Dirty oil tank for accommodating dirty oil, the dirty oil tank is connected with the machine tool;

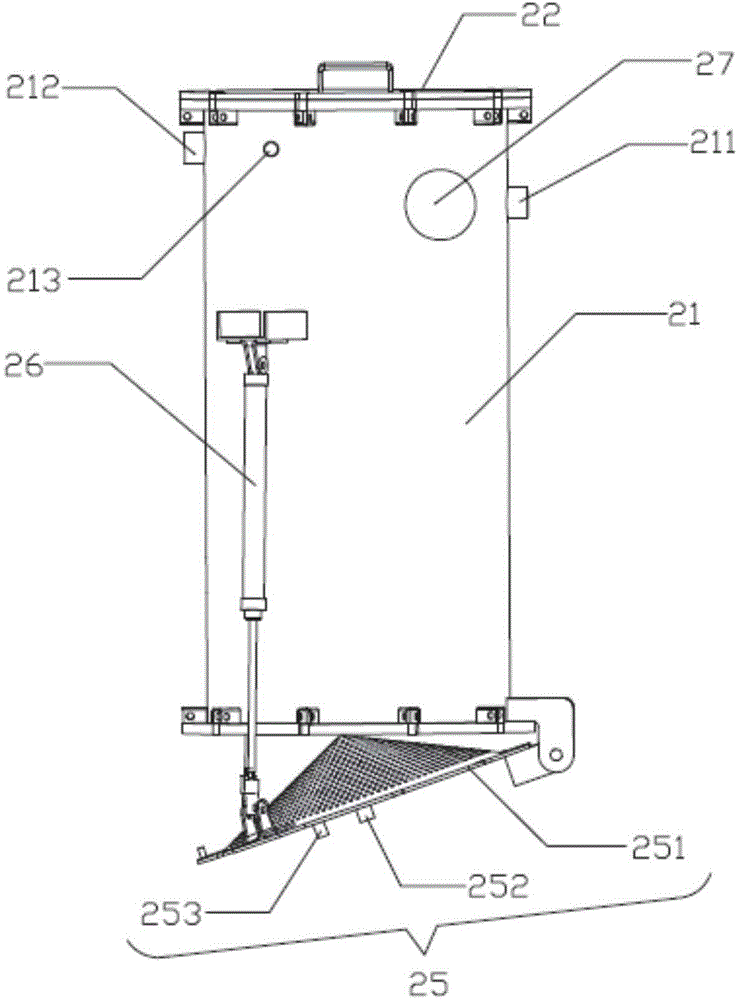

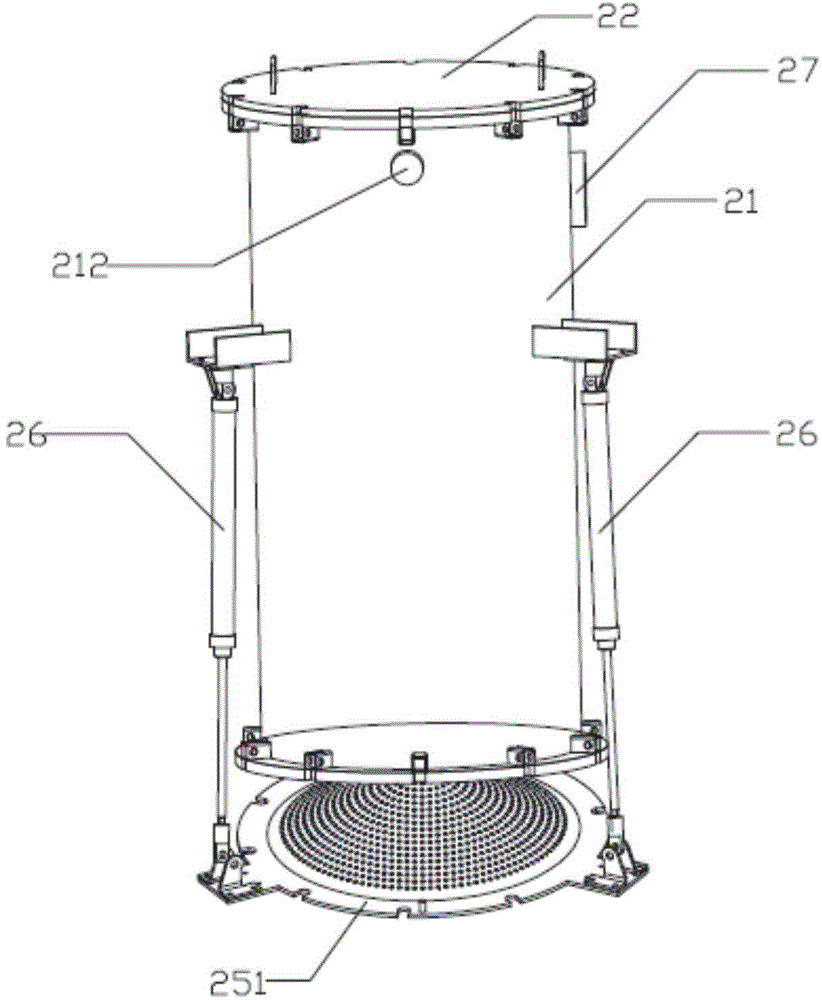

[0036] The semi-finish filter barrel is used for semi-fine filtration of dirty oil. The dirty oil inlet of the semi-finish filter barrel is connected with the dirty oil tank, and its clean oil outlet is connected with the semi-fine filter oil tank. The bottom cover plate for slag discharge that can be opened automatically, and the dirt is discharged into the sludge collection device when the bottom cover plate is opened, wherein the sludge collection device can be a chip collector or other collection devices.

[0037] A refrigeration device for cooli...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap