Method for manufacturing pressure backfilling type pipeline

A manufacturing method and pipeline technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of high requirements and complexity of pipelines, and achieve the effect of shortening excavation time and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

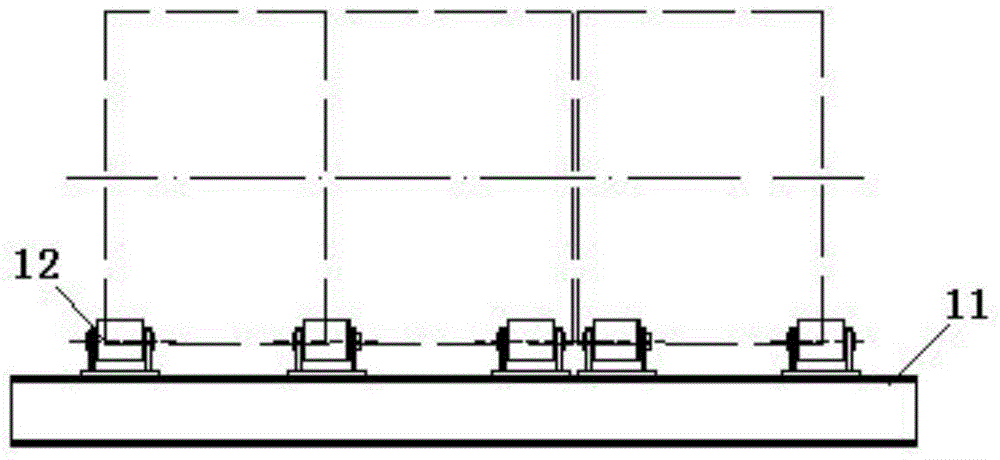

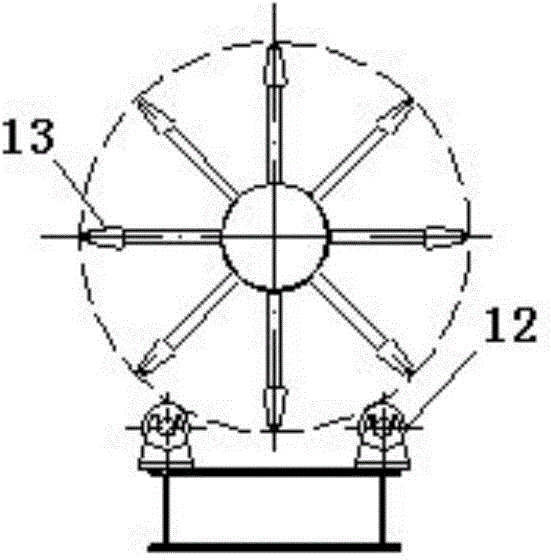

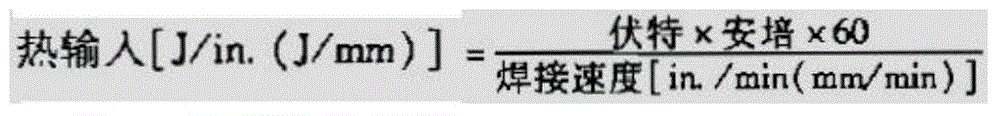

[0029] The manufacturing method of the pressure backfill type pipeline of the present invention comprises the following steps:

[0030] Step 1: Pipe Prefabrication

[0031] Scribe the steel plate so that there is only one longitudinal weld line in a section of pipe, and the longitudinal weld lines of adjacent pipe sections should be staggered by more than 300mm.

[0032] After scribing, mark the pipe segment, segment, block number, water flow direction, horizontal and vertical center line, groove angle and cutting line and other symbols.

[0033] Cutting and beveling of the steel plate after scribing. Arc cutting is not allowed. When the thickness of the steel plate is not greater than 22mm, a single "V" groove is used. When the thickness of the steel plate is greater than or greater than 22mm, the weld bevel is symmetrical "X" ” type groove to achieve accurate positioning of the steel plate in subsequent welding;

[0034] Step 2: Winding into a Tube

[0035] The steel plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com