On-line thickness measurement system for large aeronautical thin-walled part and thickness measurement method of system

A technology for thin-walled parts and thickness measurement, which is applied to metal processing machinery parts, measuring/indicating equipment, automatic control devices, etc., can solve the problems of wasting manpower and lack of guidance for processing, and achieve saving labor costs, improving the pass rate, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0031] Ultrasonic wave is a kind of mechanical longitudinal wave, which is the fluctuation generated in elastic medium due to mechanical vibration. When ultrasonic wave propagates in the same homogeneous medium, its wave velocity is a constant. When ultrasonic waves propagate from one medium to another, they will be reflected at the interface between the two mediums. Therefore, the interval time between the ultrasonic pulse sent from the surface of the measured material and the reflected pulse received from the bottom surface is proportional to the thickness of the material, and this time is converted into a thickness value representation, which is the thickness of the measured material.

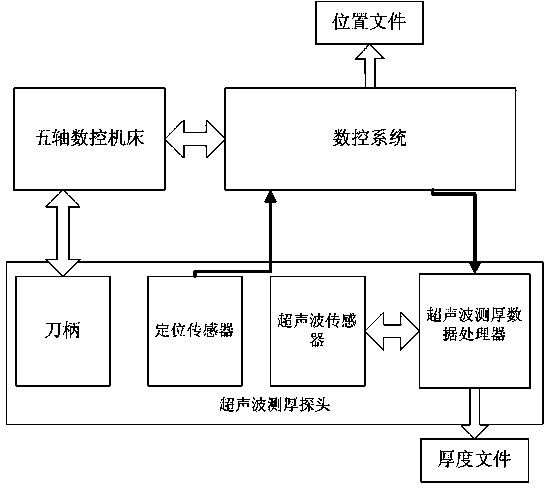

[0032] Such as figure 1 As shown, the online thickness measurement system for aviation large thin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com