Method for preparing hydrogen by using organic wastes, and apparatus thereof

A technology of organic waste and organic acid, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problem of high purity requirements of reaction substrates, achieve the effect of reducing energy consumption, reducing pollution, and fully reusing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

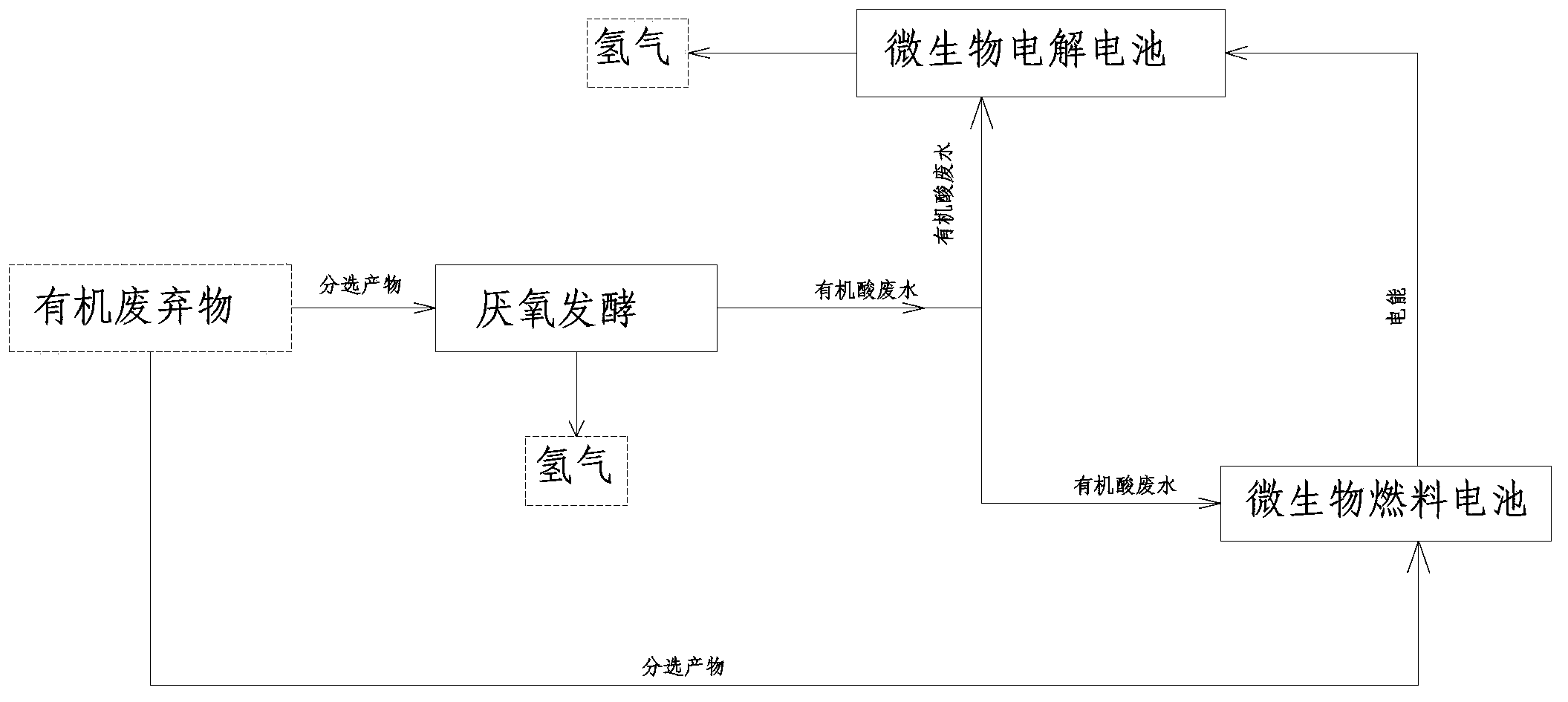

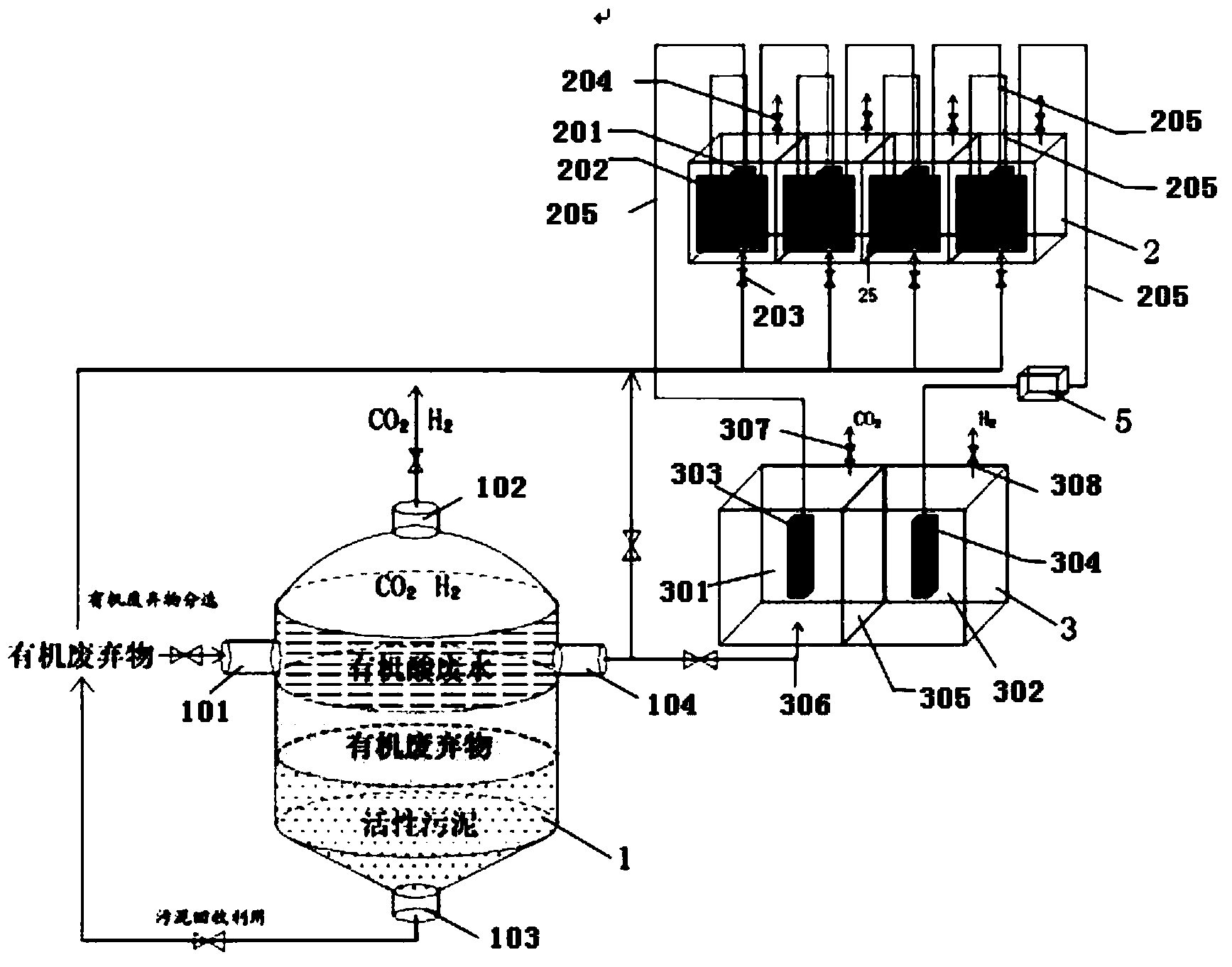

[0022] as attached figure 1 As shown, a method for producing hydrogen from organic waste is characterized in that it comprises the following steps:

[0023] First, the organic matter is pretreated;

[0024] Next, the organic waste pretreated in the first step is mixed with the inoculum containing hydrogen-producing bacteria and placed in an anaerobic fermentation reactor for anaerobic fermentation. The pH is controlled between 4 and 7.5 to produce hydrogen, carbon dioxide and organic waste. Acids and gases are separated and removed to obtain relatively pure hydrogen, and the remaining liquid containing organic acids is discharged from the anaerobic fermentation tank.

[0025] Then, part of the organic waste pretreated in the first step and part of the organic acid waste liquid generated in the second step enter the anode chamber of the microbial fuel cell, and are oxidized by electrogenic bacteria to produce carbon dioxide, protons and electrons, and the electrons pass throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com