Organic phenylboronic acid-rich polyethyleneimine modified silicon dioxide microsphere, preparation method and application of organic phenylboronic acid-rich polyethyleneimine modified silicon dioxide microsphere

A technology of polyethyleneimine and silica, which is applied in the field of functional inorganic materials and analysis, can solve the problems of low adsorption capacity and weak affinity, and achieve the effect of low abundance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

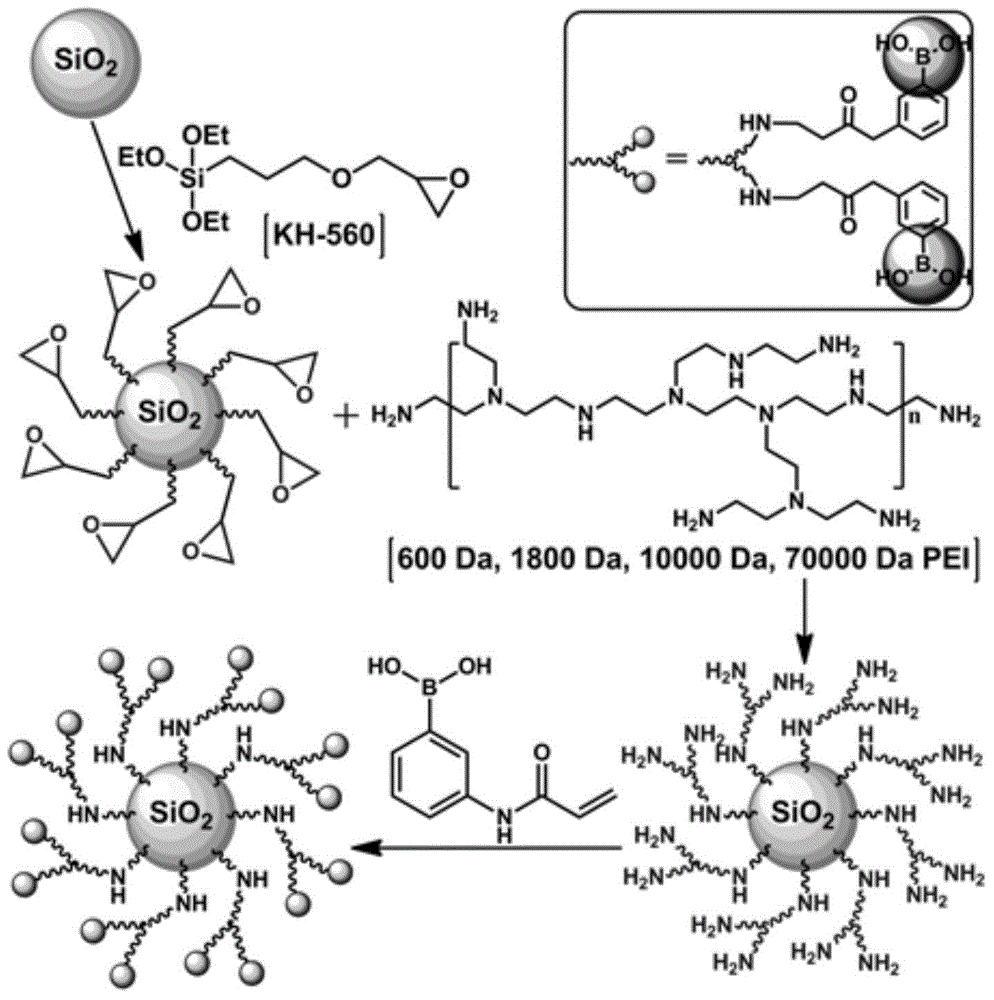

[0041] Example 1: Preparation of epoxypropyl functionalized 20 μm fully porous silica microspheres

[0042] Weigh 1 g of fully porous silica microspheres with a particle size of 20 μm, add 40 mL of dehydrated toluene, ultrasonically disperse, add 4 mL of γ-glycidyl etheroxypropyl trimethoxysilane (KH-560), stir magnetically, and protect with nitrogen. Reflux at 115°C for 24h. After the reaction, filter with suction, rinse with toluene, acetone, and anhydrous ether in sequence, and dry to obtain 20 μm fully porous silica microspheres functionalized with glycidyl groups.

Embodiment 2

[0043] Example 2: Preparation of epoxypropyl functionalized 1.4 μm non-porous silica microspheres

[0044] Weigh 1 g of non-porous silica microspheres with a particle size of 1.4 μm, add 40 mL of dehydrated toluene, ultrasonically disperse, add 4 mL of γ-glycidyl etheroxypropyl trimethoxysilane (KH-560), stir magnetically, and protect with nitrogen , 115 ° C reflux reaction for 24h. After the reaction, filter with suction, rinse with toluene, acetone, and anhydrous ether in sequence, and dry to obtain 1.4 μm non-porous silica microspheres functionalized with glycidyl groups.

Embodiment 3

[0045] Embodiment 3: the preparation of the silica microspheres of molecular weight 600Da polyethyleneimine modification

[0046] Take 1g of the epoxypropyl functionalized silica microspheres prepared in the above-mentioned Example 1 or Example 2, add 80mL of ethanol-water (1:1, v / v), after ultrasonic dispersion, add 0.75g of of polyethyleneimine. Magnetic stirring, nitrogen protection, placed in an oil bath at 65°C for reflux reaction for 12h. After the reaction, filter with suction, rinse with ultrapure water, absolute ethanol, and absolute ether in sequence, and dry to obtain polyethyleneimine-modified silica microspheres with a molecular weight of 600 Da.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com