Beneficiation method for complex Te ore

A beneficiation method and tellurium ore technology are applied in the beneficiation field of complex tellurium ore to achieve the effects of improving flotation efficiency, good separation effect and reducing the amount of beneficiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

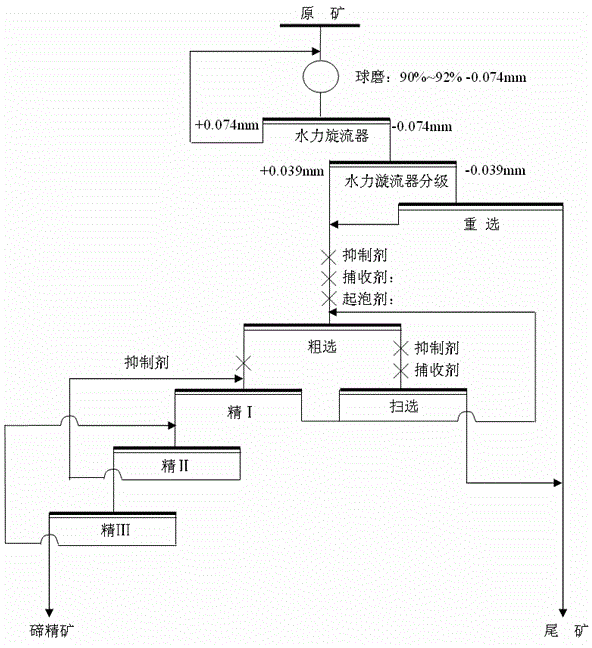

[0024] Example 1: An extremely low-grade, complex and refractory tellurium ore sample is taken from Sichuan Shimian, containing 0.08% Te, 9.04% S, 19.59% Fe, and SiO 2 4.90%, CaCO 3 24.91%, MgO 10.80%, Al 2 o 3 3.09%, using as figure 1 The process flow shown, the specific process parameters and beneficiation indicators are as follows:

[0025] (1) Selectively grind tellurium ore with a particle size of ≤12mm after crushing in a ball mill. The grinding conditions are as follows: the grinding concentration is 60%, the pH of the grinding system is 7.5-8, and the grinding products are classified by high-frequency vibrating screen, among which Parts with a particle size greater than 0.074mm are returned to the grinding machine, until the grinding fineness of the grinding product is -0.074mm, accounting for 90%, and the final grinding product is classified by a hydrocyclone;

[0026] (2) After step (1) grading, the material with a particle size below 0.039mm is re-selected and...

Embodiment 2

[0031] Example 2: Henan low-grade, complex and refractory tellurium ore sample, containing Te 0.11%, S 9.64%, Fe 20.53%, SiO 2 5.30%, CaCO 3 23.82%, MgO 11.25%, Al 2 o 3 3.22%, the specific process parameters and beneficiation indicators are as follows:

[0032] (1) Selectively grind tellurium ore with a particle size of ≤12mm after crushing in a ball mill. The grinding conditions are as follows: the grinding concentration is 62%, the pH of the grinding system is 7.5-8, and the grinding products are classified by high-frequency vibrating screen, among which Materials with a particle size above 0.074mm are returned to the grinding machine until the grinding fineness of the grinding product is -0.074mm, accounting for 92%, and the final grinding product is classified by a hydrocyclone;

[0033] (2) After step (1), the material with a particle size below 0.039mm is re-selected and discarded by a centrifuge, and a large amount of tailings are discarded to obtain a heavy meta...

Embodiment 3

[0038] Example 3: Sichuan low-grade, complex and refractory tellurium ore sample, containing Te 0.12%, S13.82%, Fe 26.20%, SiO 2 10.21%, CaCO 3 21.52%, MgO 12.65%, Al 2 o 3 4.67%, the specific process parameters and beneficiation indicators are as follows:

[0039] (1) Selectively grind tellurium ore with a particle size of ≤12mm after crushing in a ball mill. The grinding conditions are as follows: the grinding concentration is 64%, the pH of the grinding system is 7.5-8, and the grinding products are classified by high-frequency vibrating screen, among which The part with a particle size greater than 0.074mm is returned to the grinding machine, and the grinding fineness of the grinding product is -0.074mm, accounting for 92%, and the final grinding product is classified by a hydrocyclone;

[0040] (2) After step (1), the material with a particle size below 0.039mm is re-selected and discarded by a spiral separator, and a large amount of tailings are discarded to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com