A double-helix fiber-reinforced foam laminate

A fiber-reinforced, double-helix technology, applied in the field of foam laminates, can solve the problems of interface debonding, weak bonding, failure of fiber-reinforced foam composite materials, etc., and achieve the effect of improving mechanical properties and stability, and improving interface bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

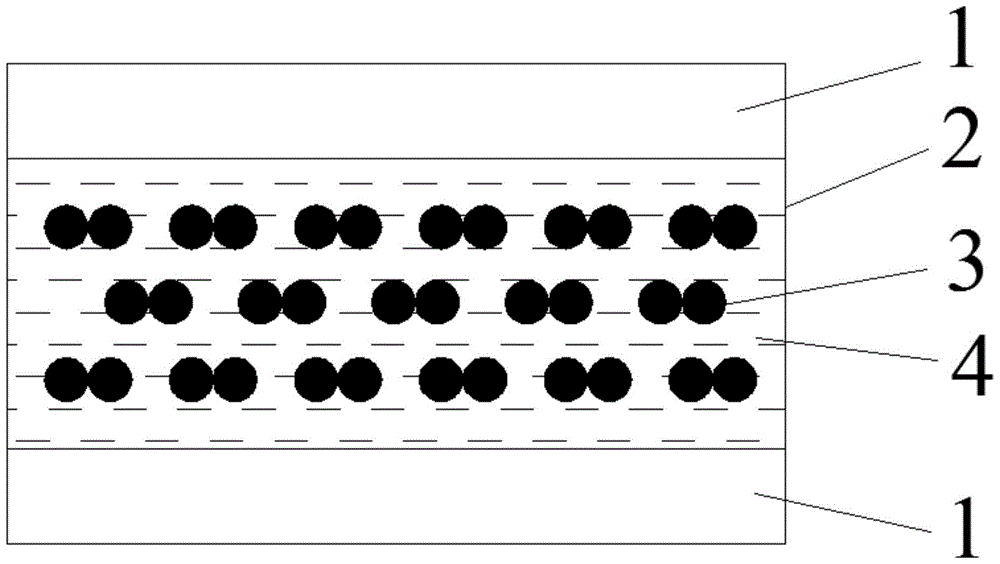

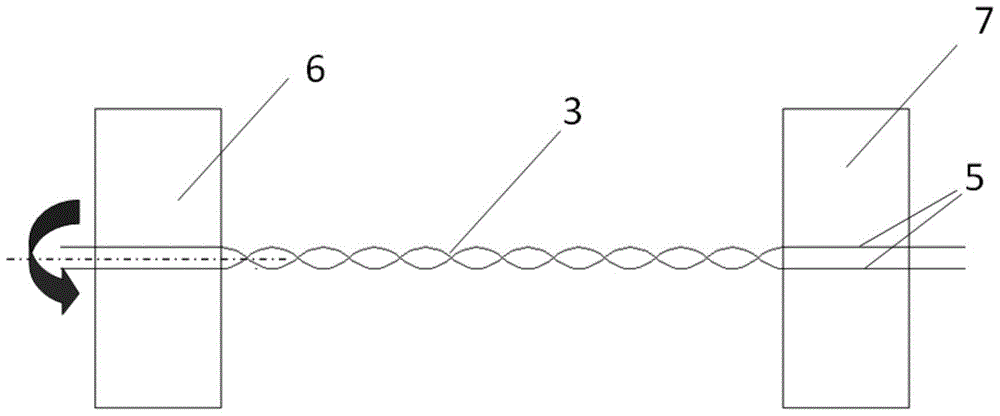

[0020] Such as figure 1 As shown, a double-helix fiber-reinforced foam laminate is mainly composed of a surface metal plate 1 and a fiber-reinforced foam core layer 2. The surface metal plate 1 is made of an aluminum alloy plate or an alloy steel laminate, and its thickness ranges from 0.2-1mm. The thickness of the fiber-reinforced foam core layer 2 is 0.5-5mm; the fiber-reinforced foam core layer 2 is arranged between two metal plates 1, wherein the fiber-reinforced foam core layer 2 is composed of double helix fibers 3 and foam matrix 4; the foam The matrix 4 is a porous resin material filled with hollow glass microspheres (with a diameter range of 2-120 μm), and the filled double-helical fibers 3 are obtained by weaving or winding natural plant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com