Glass fiber bin with feed control system

A feed control, glass fiber technology, applied in the field of silo, can solve the problems of liquid level temperature effect, powder agglomeration, silo damage, etc., to prevent the influence of liquid level and temperature, simple structure, and ensure safety production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

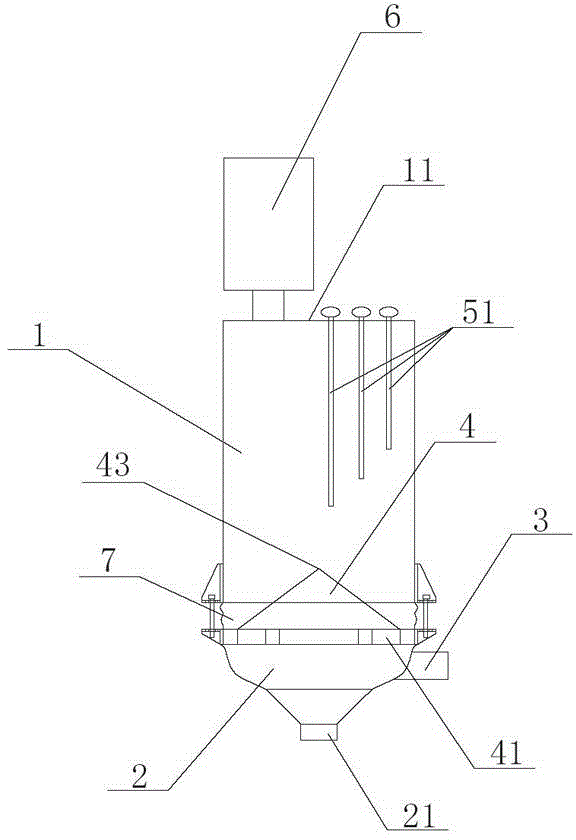

[0035] This embodiment is the most preferred for implementing the present invention. Such as Figure 1-2 As shown, in this example the

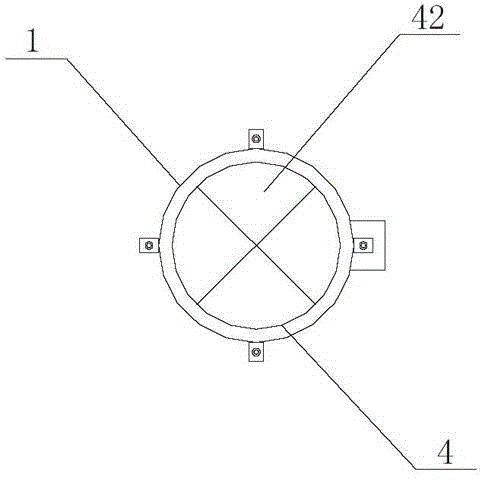

[0036] A glass fiber silo with a feed control system includes: a silo part 1; a feeding part 2, which is fixedly connected to the bottom of the silo part 1, and the fixed connection method can be a known fixed connection such as screw connection or welding. In the same way, the blanking part 2 is also provided with a discharge port 21; the tapered part 4, which is arranged in the blanking part 2, is fixedly connected with the inner wall of the blanking part 2, and the fixed connection method can also be screwed. , welding and other known fixed connection methods, the conical top 43 of the conical part 4 is set up against the feed port 11 of the silo part 1, between the bottom periphery of the conical part 4 and the inner wall of the blanking part 2 There is a gap for the material to pass through. When feeding material from the silo part 1 ...

Embodiment 2

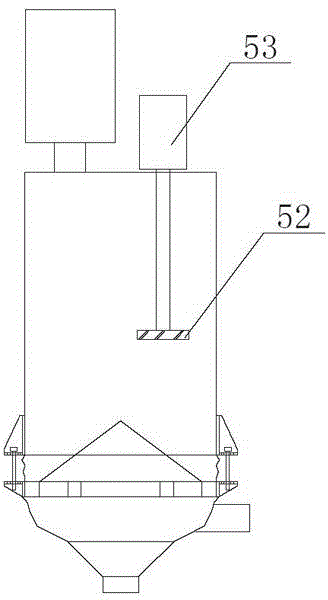

[0049] Others are the same as those described in Embodiment 1, the difference is: as image 3 As shown, the above-mentioned material level sensing group includes an impeller 52 and a motor 53, the impeller 52 is arranged in the silo part 1, the rotating shaft of the motor 53 is fixedly connected to the impeller 52, and is used to drive the impeller 52 to rotate in the silo part, The motor 52 is also electrically connected to an industrial computer (not shown), and the industrial computer is electrically connected to an alarm (not shown), for when the motor 52 is running, the industrial computer sends an alarm command to the alarm, and the alarm alarm. The working process is: when there is material, the impeller cannot rotate due to the pressure of the material. If the material fed into the silo is not in place, the impeller will run with the rotation of the motor, and the motor will send a corresponding electrical signal to the industrial computer. The industrial computer con...

Embodiment 3

[0051] Others are the same as those described in Embodiment 1 or 2, except that the tapered portion 4 is arranged in the silo portion 1 and is fixedly connected with the inner wall of the silo portion 1, and the bottom of the tapered portion 4 is connected with the There is a gap for material to pass between the inner walls of the silo part 1 . The tapered part 4 can also be centrally arranged in the bin part 1 . The support frame 41 can be fixedly connected with the inner wall of the bin part 1 . This setting is also similar to the effect achieved in Embodiment 1, and the user can choose to install it as needed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com