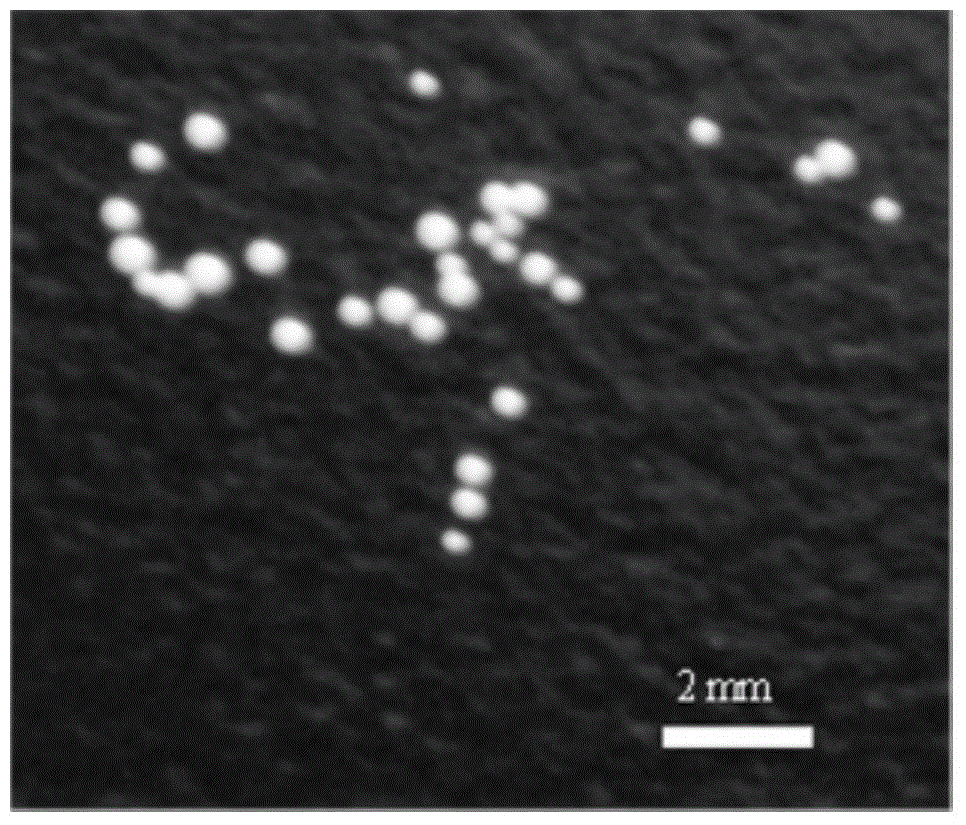

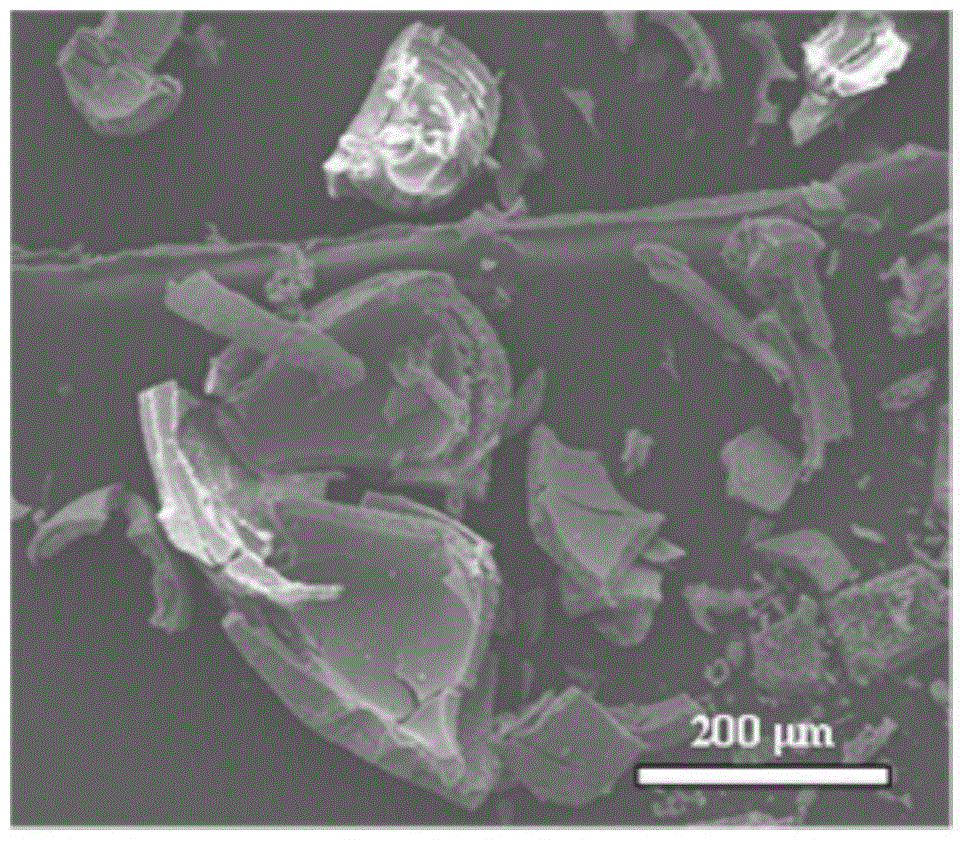

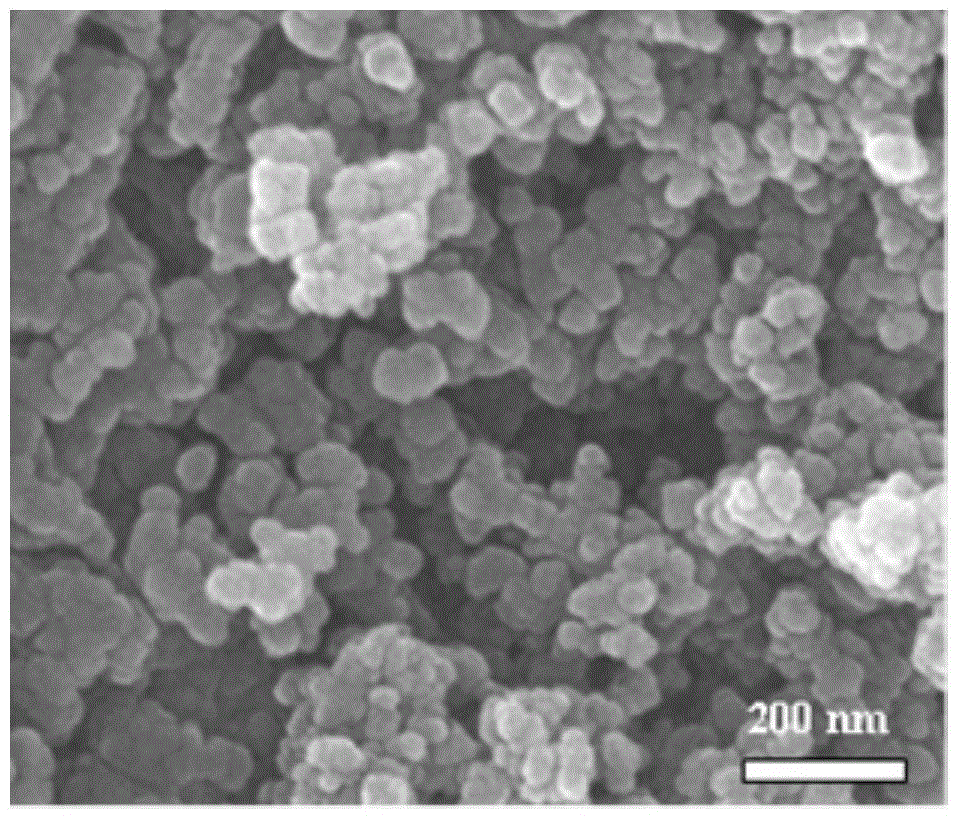

Preparation method of hollow titanium dioxide millimeter spheres consisting of nanoparticles

A nanoparticle, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of difficult separation and low recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0027] Specific embodiment one: the preparation method of the hollow titania millimeter sphere composed of nanoparticles in this embodiment is carried out according to the following steps:

[0028] 1. Weigh the titanium source, tetrapropylammonium hydroxide aqueous solution with a concentration of 50% by volume, deionized water and anion exchange resin, wherein the mass ratio of the titanium source to the tetrapropylammonium hydroxide aqueous solution is 1:1~5 , the mass ratio of titanium source to deionized water is 1:5-30, the mass ratio of titanium source to anion exchange resin is 1:2-15;

[0029] 2. Mix the tetrapropylammonium hydroxide aqueous solution weighed in step 1 and deionized water evenly to obtain a mixed solution, and then add the titanium source to the mixed solution under stirring at room temperature, and then continue to stir for 1~ 6h, add anion exchange resin, stir for 6-24h, and obtain the precursor solid-liquid mixture;

[0030] 3. Put the precursor sol...

specific Embodiment approach 2

[0035] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the titanium source in Step 1 is tetrabutyl titanate or tetraisopropyl titanate. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the room temperature in step 2 refers to 15°C to 30°C. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com