Microporous heat insulation board with high anti-radiation rate and low heat conductivity coefficient and preparation method thereof

A thermal insulation board and microporous technology, applied in the field of thermal insulation, can solve the problems such as the use of thermal insulation boards for high radiation infrared energy-saving coatings that have not yet been seen, and achieve the effects of reducing liquid metal crusts, good thermal insulation performance, and convenient on-site construction and dismantling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

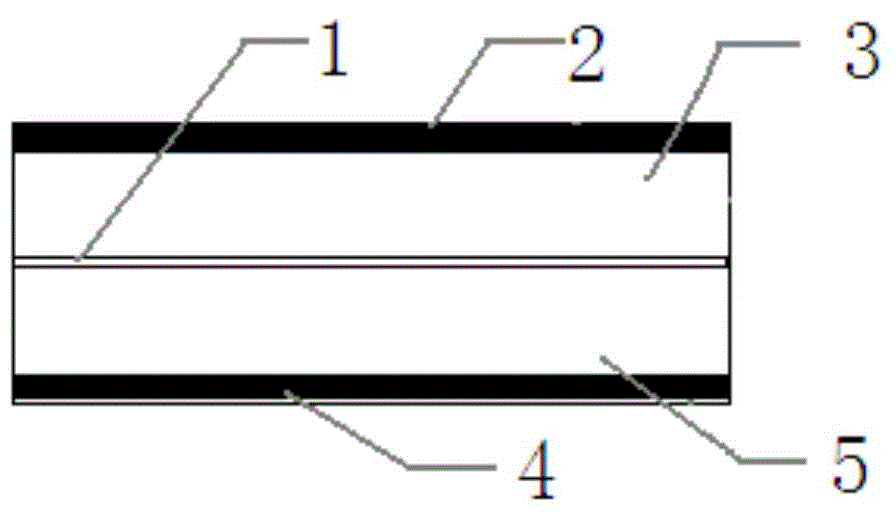

Image

Examples

Embodiment 1

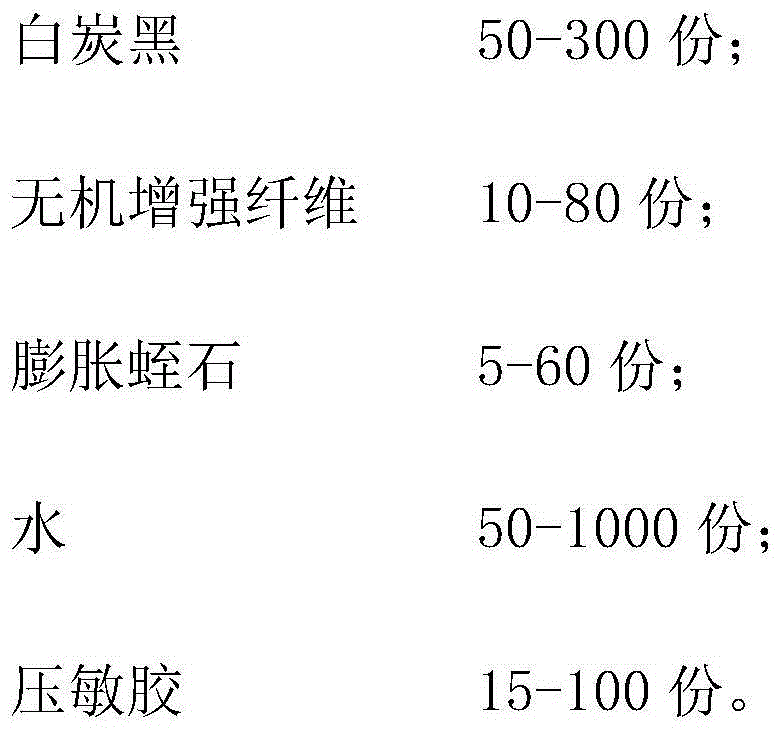

[0042] (1) Prepare pressure-sensitive adhesive solution: weigh 72g of pressure-sensitive adhesive in 680g of water, and mix evenly;

[0043] (2) Weigh 200g of fumed silica, 50g of expanded vermiculite, and 18g of glass fibers are mixed uniformly;

[0044] (3) After mixing the weighed pressure-sensitive adhesive solution in the steel basin evenly, add the mixed solid powder, stir evenly, and obtain the heat insulating material;

[0045] (4) Apply the thermal insulation material in step (3) on the fiber mesh cloth with aluminum foil on the plate, and scrape it flat, with a thickness of about 2-3mm.

[0046] (5) Cover the upper part with a layer of high-temperature-resistant fiber mesh cloth as a reinforcing rib, and then coat a layer of heat-insulating material with a thickness of about 2 to 3 mm, and press and form it.

[0047] (6) Put the above products in a small oven to dry part of the water, control the drying temperature not to exceed 230°C, and then use a needle board de...

Embodiment 2

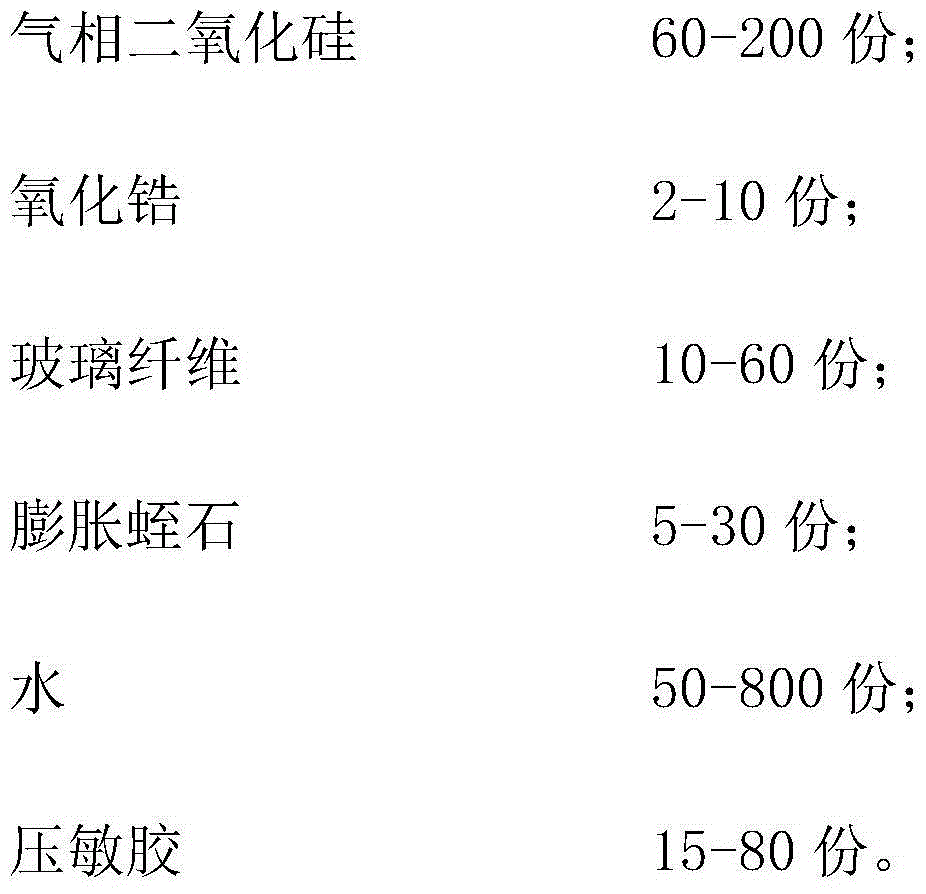

[0060] (1) Prepare pressure-sensitive adhesive solution: weigh 72g of pressure-sensitive adhesive in 680g of water, and mix evenly;

[0061] (2) Weigh fumed silica 200g, zirconia 5g, expanded vermiculite 20g, glass fiber 18g and mix uniformly;

[0062] (3) After mixing the weighed pressure-sensitive adhesive solution in the steel basin evenly, add the mixed solid powder, stir evenly, and obtain the heat insulating material;

[0063] (4) Apply the thermal insulation material in step (3) on the fiber mesh cloth with aluminum foil on the plate, and scrape it flat, with a thickness of about 2-3mm.

[0064] (5) Cover the upper part with a layer of high-temperature-resistant fiber mesh cloth as a reinforcing rib, and then coat a layer of heat-insulating material with a thickness of about 2 to 3 mm, and press and form it.

[0065] (6) After drying part of the water in a small oven, the needles are punched to facilitate the evaporation of water.

[0066] (7) After drying, spray a la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com