Coupling method of mto process and depropanization process before naphtha cracking

A naphtha and depropanization technology, which is applied in the direction of hydrocarbon cracking, hydrocarbon production from oxygen-containing organic compounds, organic chemistry, etc., can solve the problems of low benefit of raw material products, unreasonable process design, large investment, etc., and achieve reduction Investment and production costs, reduction of energy consumption, and the effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

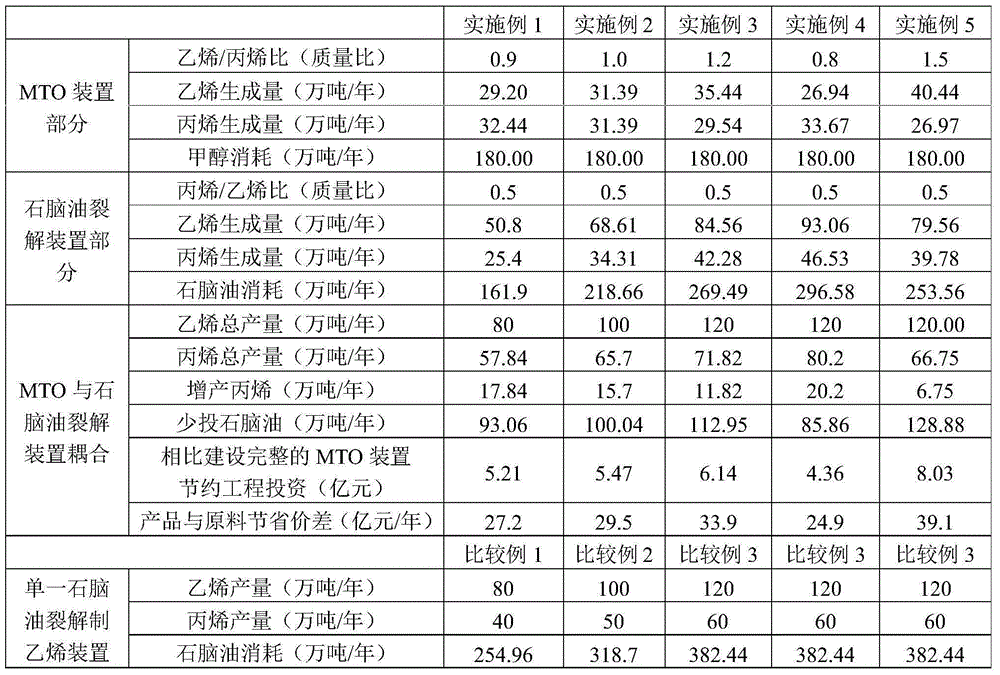

[0021] Adopt the coupling method of the MTO process described in the present invention and the depropanization process flow before naphtha cracking, keep the 800,000 tons / year of ethylene product volume of the whole coupling flow unchanged, and the operating condition of the pre-cutting tower tower top is: the temperature is 8°C, the pressure is 2.6MPaG. The MTO reaction scale is 1.8 million tons / year, the raw material is methanol, the mass ratio of propylene to ethylene in the cracking gas is 1:2, and the mass ratio of ethylene to propylene in the MTO product gas is 0.9:1. The specific data are shown in Table 1 .

Embodiment 2

[0025] According to the conditions described in Example 1, the ethylene product volume of the entire coupling process is kept constant at 1 million tons per year, and the operating conditions at the top of the pre-cutting tower are: temperature is 0° C., and pressure is 2.0 MPaG. The MTO reaction scale is 1.8 million tons / year, the raw material is methanol, the mass ratio of propylene to ethylene in the cracking gas is 1:2, and the mass ratio of ethylene to propylene in the MTO product gas is 1:1. The specific data are shown in Table 1 .

Embodiment 3

[0029] According to the conditions described in Example 1, the ethylene product volume of the entire coupling process is kept constant at 1.2 million tons per year, and the operating conditions at the top of the pre-cutting tower are: the temperature is -2°C, and the pressure is 1.8 MPaG. The MTO reaction scale is 1.8 million tons / year, the raw material is methanol, the mass ratio of propylene to ethylene in the cracking gas is 1:2, and the mass ratio of ethylene to propylene in the MTO product gas is 1.2:1. The specific data are shown in Table 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com