Preparation method of modified welan gum

A Welan gum and modification technology, which is applied in the field of preparation of modified Welan gum, can solve the problems of low effective viscosity and poor ability to co-sand, and achieve the effect of solving poor water solubility and enhancing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

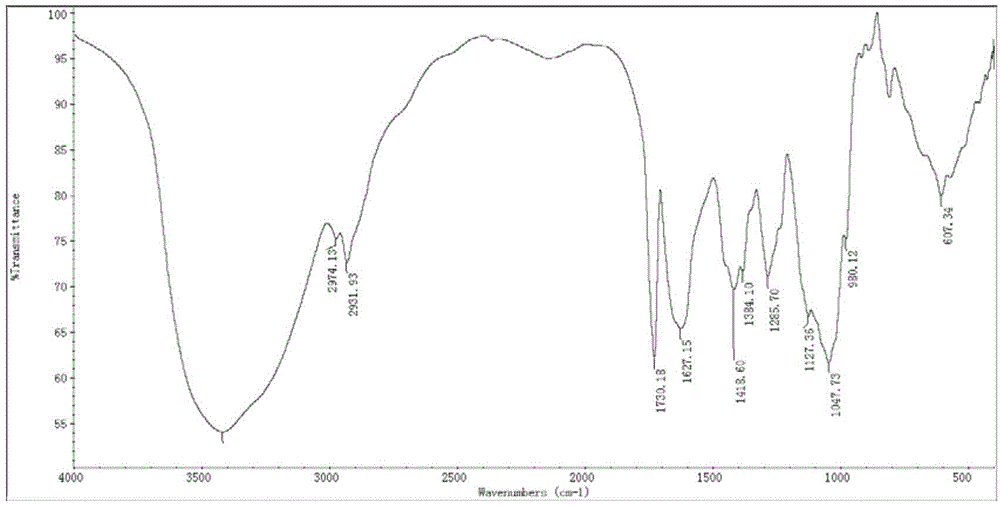

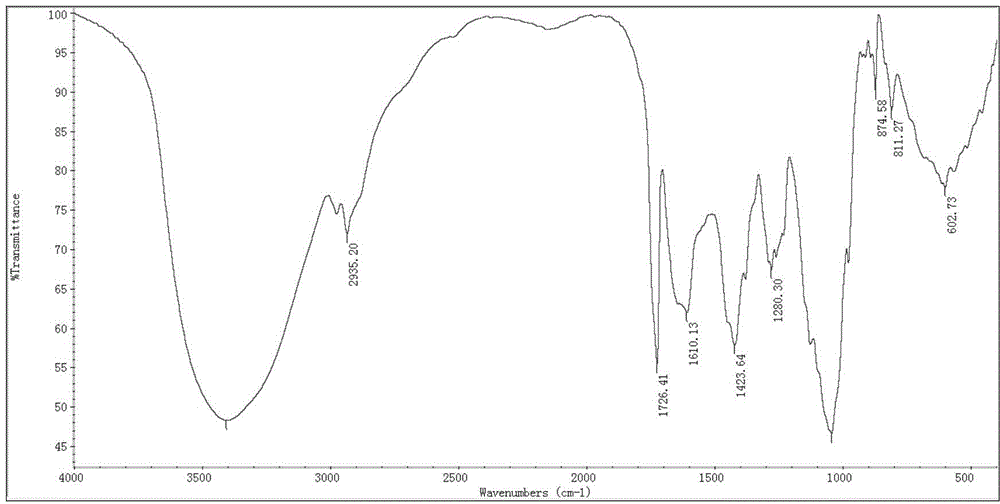

Image

Examples

Embodiment 1

[0031] In a three-necked flask, take Welan gum and dissolve it in water to prepare an aqueous solution with a concentration of 10g / L, and stir at a speed of 450rpm to allow it to fully dissolve; in the aqueous solution prepared by 11-bromoundecanoic acid and potassium acetate, Wherein, the concentration of 11-bromoundecanoic acid is 1g / L, and the concentration of potassium acetate is 1g / L, and the quality of controlling Welan gum: 11-bromoundecanoic acid is 10:1; The aqueous solution made of bromoundecanoic acid and potassium acetate was added dropwise at a constant speed; reacted at normal pressure, 60°C, 450rpm under stirring conditions for 1h, collected the reaction solution, poured it into absolute ethanol to precipitate the product, washed, and heated at 40°C drying and crushing to obtain the modified Welan gum product. The product was dissolved in 400mL of 2wt% KCl solution and dissolved within 2h. Take the product and configure it into a 0.7wt% aqueous solution, and th...

Embodiment 2

[0033] In a three-necked flask, take Welan gum and dissolve it in water to prepare an aqueous solution with a concentration of 5g / L, and stir it at a speed of 500rpm to allow it to fully dissolve; in the aqueous solution prepared by 11-bromoundecanoic acid and potassium carbonate, Wherein, the concentration of 11-bromoundecanoic acid is 2g / L, and the concentration of potassium carbonate is 5g / L, and the quality of controlling Welan gum: 11-bromoundecanoic acid is 5:2; The aqueous solution made of bromoundecanoic acid and potassium carbonate was added dropwise at a constant speed; reacted at normal pressure, 55°C, 500rpm under stirring conditions for 3h, collected the reaction solution, poured it into absolute ethanol to precipitate the product, washed, and heated at 45°C drying and crushing to obtain the modified Welan gum product. The product was dissolved in 400mL of 2wt% KCl solution and dissolved within 2h. The product was configured into a 0.7wt% aqueous solution, and th...

Embodiment 3

[0035] In a three-necked flask, take Welan gum and dissolve it in water to prepare an aqueous solution with a concentration of 10g / L, and stir it at a speed of 550rpm to fully dissolve it; in the aqueous solution prepared by 11-bromoundecanoic acid and sodium hydroxide , wherein, the concentration of 11-bromoundecanoic acid is 5g / L, and the concentration of sodium hydroxide is 6g / L, and the mass ratio of controlling Welan gum: 11-bromoundecanoic acid is 2:1; The aqueous solution made of 11-bromoundecanoic acid and sodium hydroxide was added dropwise at a constant speed; reacted at normal pressure, 80°C, and stirred for 6 hours, collected the reaction liquid, poured it into absolute ethanol to precipitate the product, washed it, and Dry at 50°C and pulverize to obtain the modified Welan gum product. The product was dissolved in 400mL of 2wt% KCl solution and dissolved within 2h. The product was prepared as a 0.7wt% aqueous solution, and the measured viscosity was 0.879pa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com