Spinning forming intelligent control system

An intelligent control system and spinning technology, applied in textiles and papermaking, can solve problems such as inaccurate positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

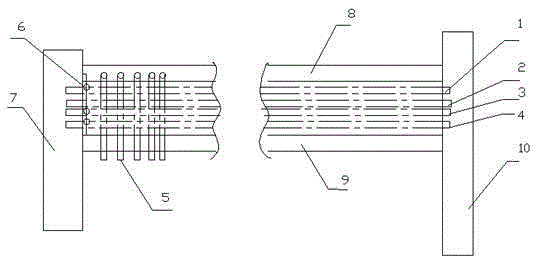

[0030] In this embodiment, a position sensor 6 is installed at the initial position 4, the pull-back position 3 and the highest position 1 that the outline board of the existing spinning frame needs to reach. It is used to detect whether the ring board is accurately in place, and the ring board guides the yarn. Winding on bobbin 5. Such as figure 1 As shown, the frame head 7, machine tail 10, upper beam 8, and lower beam 9 form four positions for the movement of the ring plate, and these four positions are located between the upper beam 8 and the lower beam 9.

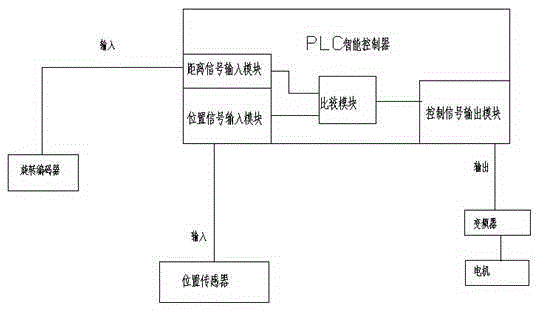

[0031] Such as figure 2 As shown, the present invention needs a rotary encoder, a PLC intelligent controller, a frequency converter and a motor, and the rotary encoder is used to calculate the rising and falling distance of the ring plate, and transmits the calculated distance signal to the PLC intelligent controller, and the PLC controller It also needs to receive the position signals transmitted by the three posit...

Embodiment 2

[0038] This embodiment includes a signal acquisition unit, a control unit, and an execution unit; the signal acquisition unit is used to collect the signals of whether the ring plate has reached the initial position, the position of pulling the middle yarn, the pull-back position and the highest position, and the control unit uses After receiving the signal collected by the signal acquisition unit, comparing the collected signal with the set signal and then outputting the control signal, the execution unit is used to receive the control signal output by the control unit, and execute the control signal according to the received control signal. Control the rise and fall of the ring plate.

[0039] The signal acquisition unit includes a position sensor and a rotary encoder. There are three sensors, which are respectively installed at the initial position, the pull-back position and the highest position. Both the position sensor and the rotary encoder are connected to the control u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com