Arc-shaped steel plate carrier vehicle for water delivery tunnel

A technology for arc-shaped steel plates and water delivery tunnels, which is applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as increased costs, low construction efficiency, and damage to steel plate surface corrosion, so as to save construction costs, improve construction efficiency, and alleviate The effect of traffic jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment the present invention is further described.

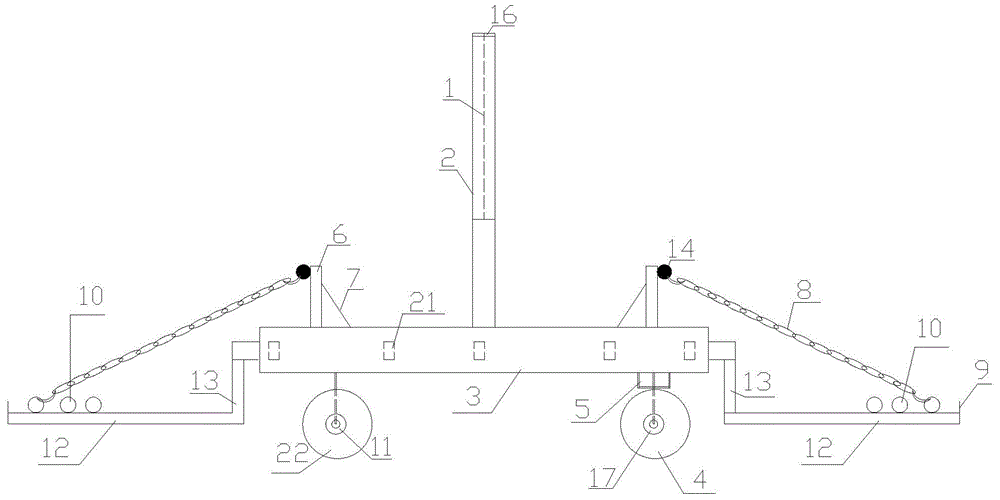

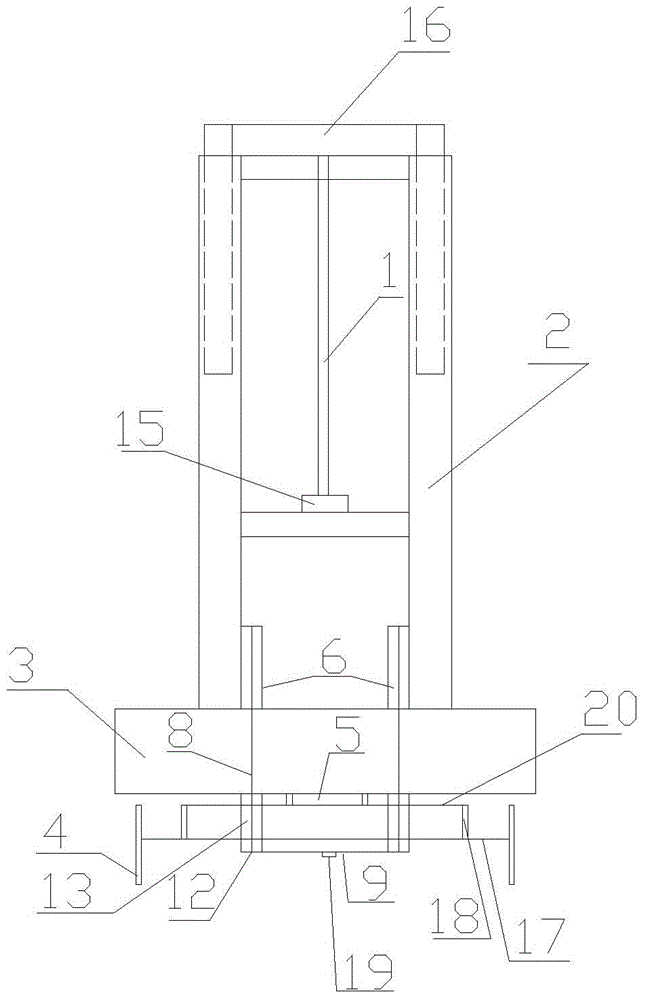

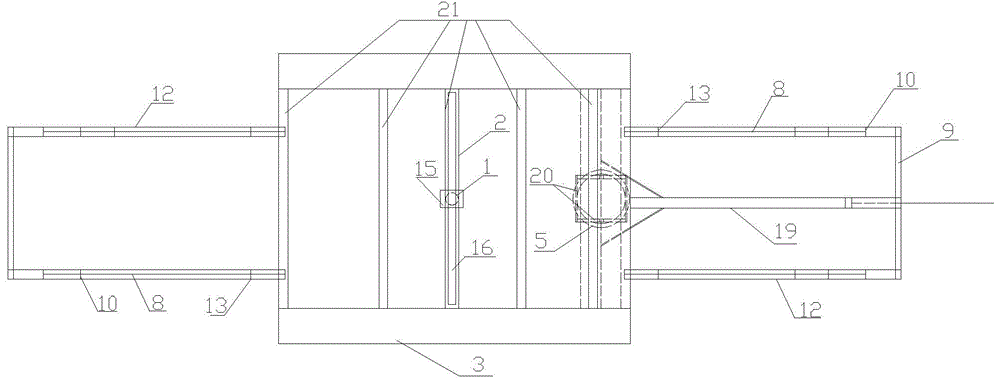

[0018] see figure 1 —3, the arc-shaped steel plate transport vehicle in the water delivery tunnel, including the vehicle frame 3, the front wheel pair 4, the rear wheel pair 22, the front wheel shaft 17 and the rear wheel shaft 11; There is a hydraulic cylinder 1, and the piston of the hydraulic cylinder 1 is connected with a telescopic support 16; a pair of positioning columns 6 are respectively arranged on the upper parts of the two ends of the vehicle frame 3, and a reinforcement support 7 is provided between the inside of the positioning column 6 and the vehicle frame 3; The end is provided with a lifting frame 12, and the car frame 3 is connected with the lifting frame 12 through the bracket connecting rod 13; the end of the lifting frame 12 is provided with a limit card 9; the end of the lifting frame 12 is provided with a positioning pile 10; On the position adjustment pile 10, be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com