Centralized air-conditioner exhausted-air heat/cold energy recovery system

A recovery system and centralized technology, applied in the field of energy saving of air conditioning systems, can solve the problems of increasing energy consumption of units, affecting comfort, and expensive heat exchangers, improving heat dissipation in summer and cooling in winter, and improving refrigeration and production. Improved thermal efficiency and overall energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

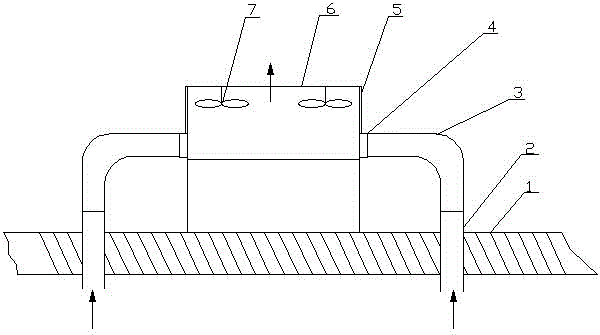

[0009] In order to facilitate construction and installation and reduce the length of connecting pipes, the system of the present invention should generally be arranged on the roof, such as figure 1 Shown: including roof 1, exhaust pipe 2, exhaust air guide pipe 3, exhaust air inlet 4, unit air inlet 5, air-cooled heat pump unit 6 and fan 7. Wherein the outlet end 2 of the exhaust pipe is connected with the inlet end of the exhaust air guide pipe 3 , and the outlet end of the exhaust air guide pipe 3 is connected with the exhaust air inlet 4 . Exhaust air heat (cold) recovery system has introduced left and right two exhaust air ducts 3. The exhaust air inlet 4 is located directly below the air inlet 5 of the unit, and is drawn out by 30 cm for introducing the exhaust air into the heat pump unit. The exhaust air guide pipe 3 is a circular air duct, and its insulation material is polyurethane foam with a thickness of 25 millimeters, and one deck of aluminum foil protective layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com