A visual test device for mechanical properties of natural gas hydrate deposits

A technology for hydrate deposits and mechanical properties, which is applied in the direction of measuring devices, strength properties, and the use of stable tension/pressure testing material strength, etc., can solve problems such as large volume, poor penetration performance, and heavy weight, and achieve X Good ray penetration performance, guaranteed penetration performance, and light overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

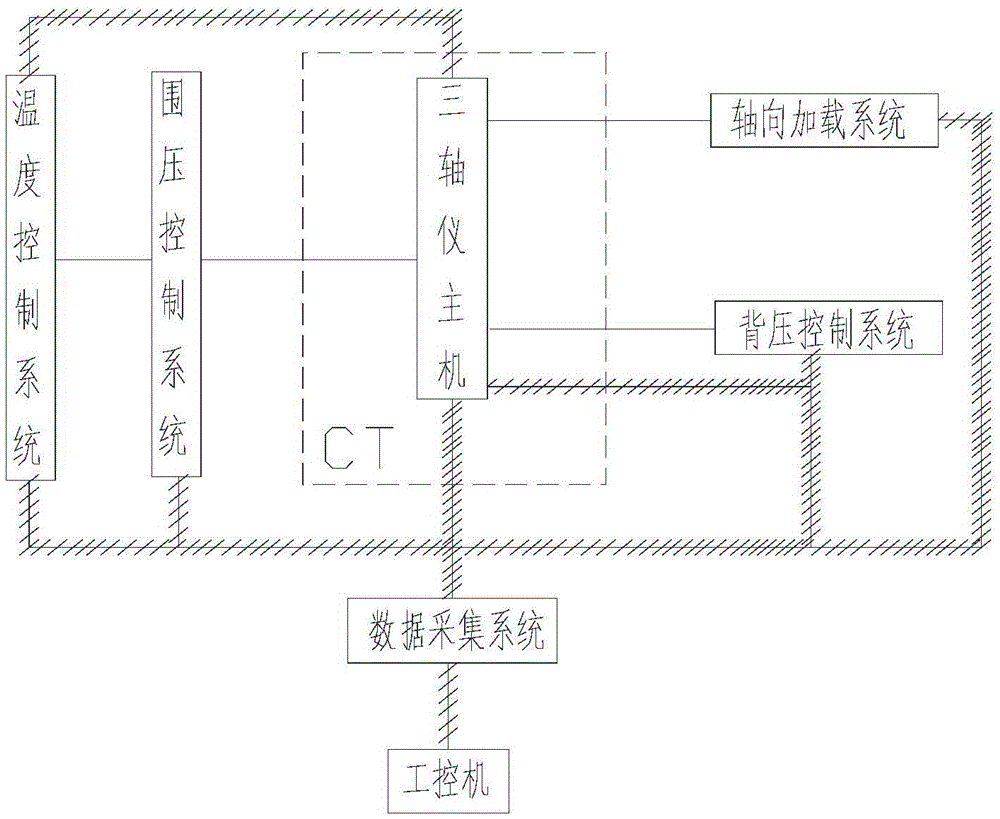

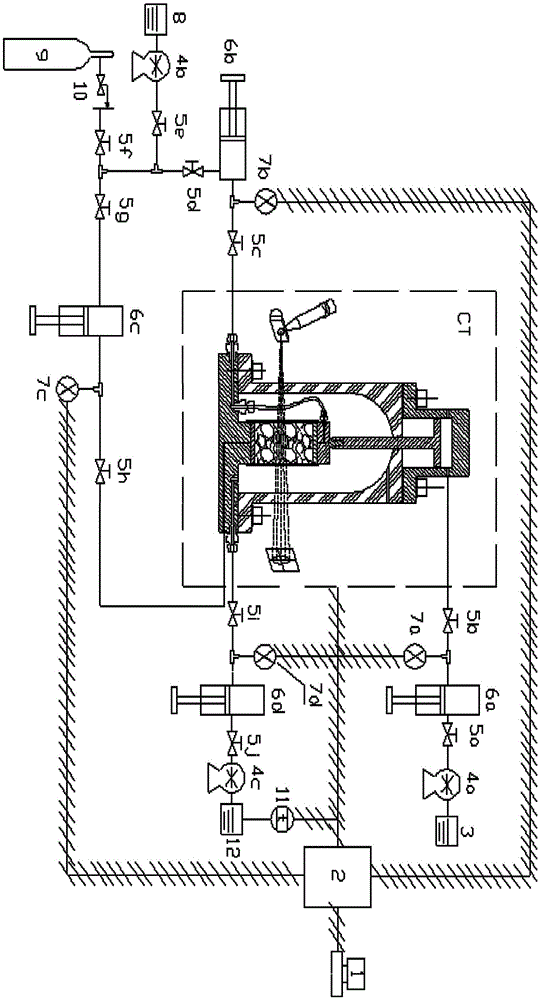

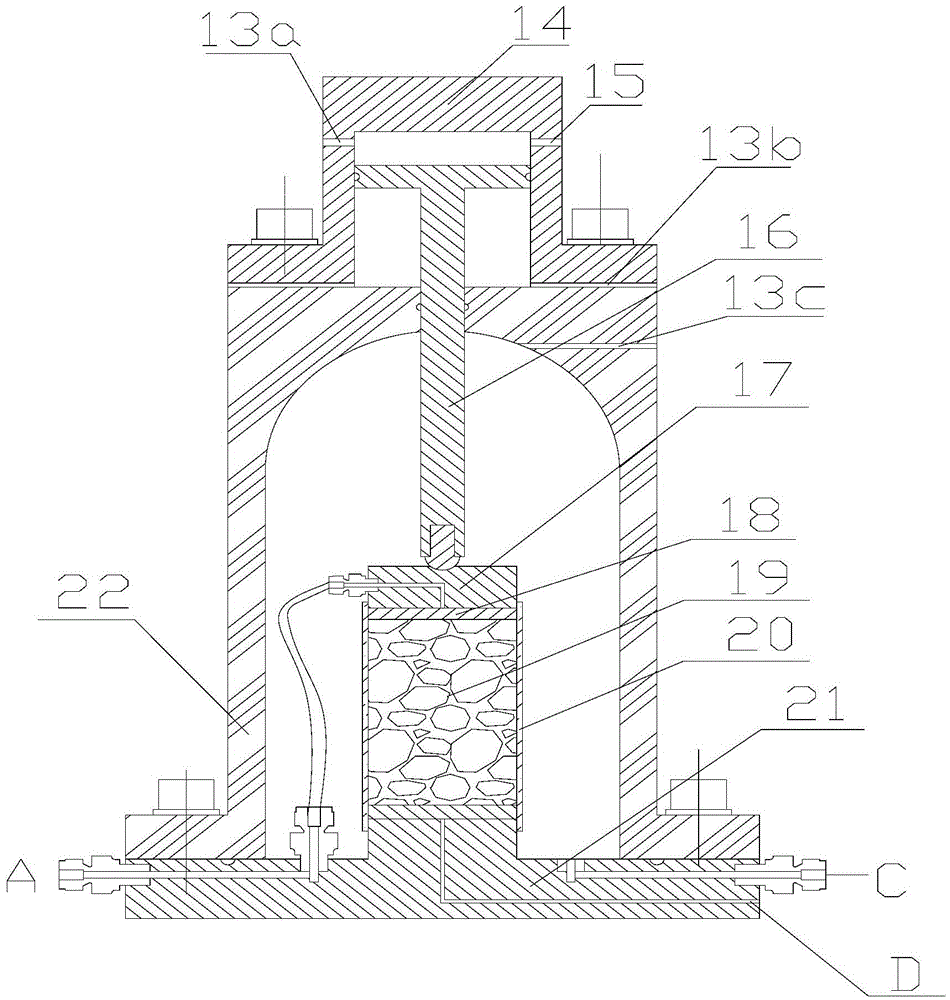

[0034] figure 1 Shown is a working principle diagram of a visual test device for the mechanical properties of natural gas hydrate deposits. process and pore pressure in the triaxial compression process; the temperature control system controls the temperature of the gas hydrate deposit formation and decomposition process and the triaxial compression process by reducing the temperature of the hydraulic oil in the confining pressure control system; the confining pressure control system It is mainly used to maintain the confining pressure during the formation and decomposition of natural gas hydrate deposits and the triaxial compression process; the axial loading system injects hydraulic oil through the plunger pump to push the piston to control the axial loading; the CT machine photographs the hydrate during the entire test process The image of the evolution law of the microscopic pore structure of the sediment; the parameters during the test, such as temperature and pressure sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com