Hydrate sediment in-situ permeability pressure gradient and mechanical property measuring system

A technology of hydrate deposits and pressure gradients, applied in permeability/surface area analysis, measuring devices, scientific instruments, etc., can solve problems such as hindering CT shooting, specific analysis cannot be observed and studied, and pressure changes and hydrate formation areas are difficult to implement. , to achieve the effect of reducing the occlusion problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

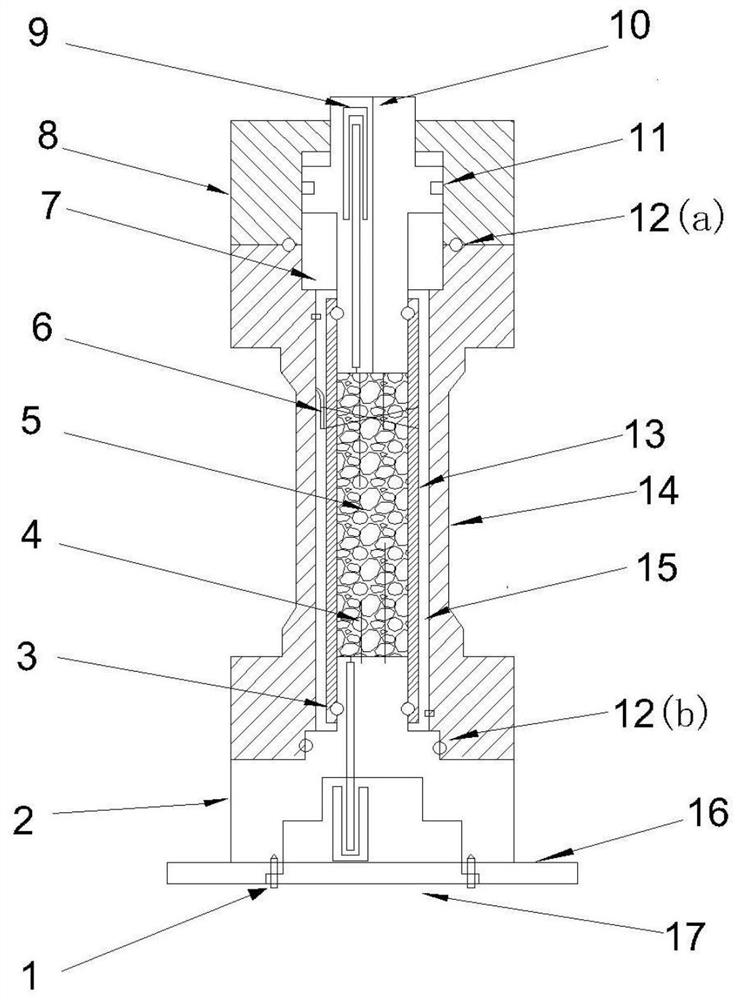

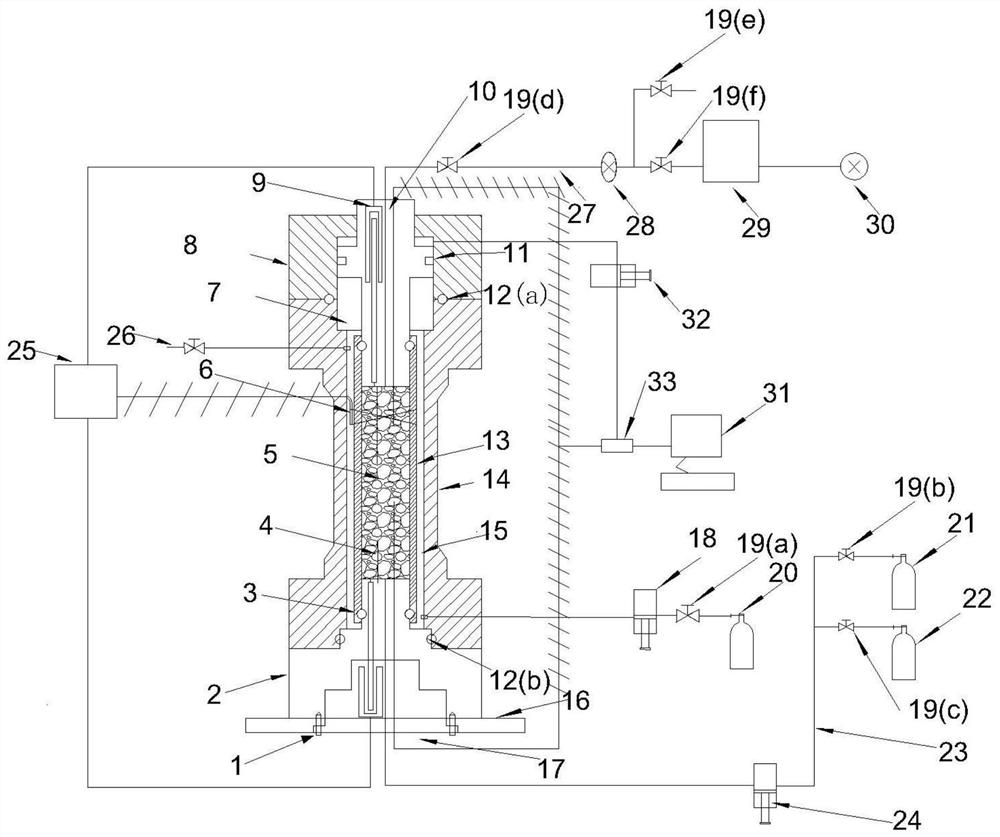

[0030] Such as figure 1 , figure 2As shown, the present invention provides a system for measuring in-situ permeability pressure gradient and mechanical properties of hydrate deposits, which includes: reaction kettle, sediment sample 5, confining pressure loading device, pore pressure loading device, axial pressure loading device, refrigeration device, data acquisition device and control display 31. Specifically, the reaction kettle includes a base, a pressure chamber main body 14 and an upper end cover 8 . Wherein, the pressure chamber main body 14 adopts a hollow "I"-shaped structure, and the middle parts of the upper and lower ends of the pressure chamber main body 14 are respectively provided with a first cylindrical groove whose diameter is larger than the hollow part, and the two first cylindrical grooves There is no communication with the hollow part of the pressure chamber main body 14; the base includes a bottom base 2 and a base substrate 16 connected by a connecti...

Embodiment 2

[0042] When using the above-mentioned in-situ permeability pressure gradient and mechanical property measurement system for hydrate deposits to measure the mechanical properties of hydrate deposits, the following steps are included:

[0043] (1) Connecting pipeline: the device of the present invention is placed on the CT equipment stage, and according to figure 2 As shown, the reaction kettle is respectively connected with the confining pressure loading device, the pore pressure loading device, the axial pressure loading device, the refrigeration device and the data acquisition device.

[0044] The specific connection method is:

[0045] Confining pressure loading device: connect one end of the confining pressure air intake line to the confining pressure air inlet provided at the lower part of the pressure chamber main body 14, and connect the other end to the confining pressure loading pump 18, needle valve 19(a) and nitrogen cylinder 20 in sequence, and the nitrogen cylinde...

Embodiment 3

[0057] When the above gas hydrate deposit in-situ permeability pressure and mechanical property measurement system is used to measure the mechanical properties, specifically, the following steps are included:

[0058] (1)-(6): The process is consistent with the steps (1)-(6) in the second embodiment.

[0059] (7) Osmotic pressure measurement stage: the experiment is measured by the constant pressure method. After the consolidation is completed, the pore pressure loading pump 24 is adjusted to a stable pressure of 10 MPa, and the pressure of the back pressure valve 28 at the gas outlet of the pore pressure is adjusted to 6 MPa. During the sampling process, the flow rate and flow rate change until the final flow rate of the gas flow meter 30 remains at a constant value, and the flow rate and pressure are brought into the permeability formula to obtain the permeability value, and at the same time, the pressure at different positions in the permeation process is observed.

[0060]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com