Image sensor noise restraint full-chip ESD protection structure

An image sensor, ESD protection technology, applied in the direction of image communication, electric solid-state devices, semiconductor devices, etc., can solve problems such as short circuit, weakening the full-chip ESD protection ability of mixed-voltage image sensors, and chip failure, so as to improve stability and reliability Sex, improve protection ability, enhance the effect of protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0034] First, the image sensor noise suppression full-chip ESD protection structure and application conditions provided by the present invention are described:

[0035] (1) Unit structure

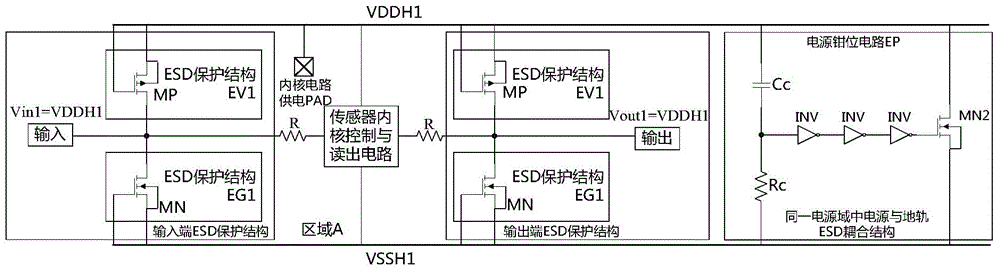

[0036] Such as image 3 As shown, the first signal input terminal and output terminal in the first area A are respectively connected to the first input and output metal pads, and the first power rail protection circuit EV1 and the first ground are connected in parallel between the first input and output metal pads The rail protection circuit EG1 protects the first power rail VDDH1 and the first ground rail VSSH1. In this preferred structure, the power clamp circuit EP is connected in series between the first power rail VDDH1 and the first ground rail VSSH1; the power clamp circuit EP connects the first A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com