High-power flexible packaged lithium ion battery and processing process thereof

A single cell and positive electrode technology, which is applied in the field of high-power flexible packaging lithium-ion batteries and their manufacturing processes, can solve problems such as reducing battery safety, and achieve the effects of reducing battery interface impedance, reducing battery internal resistance, and improving battery hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1, Winding single cell

[0063] A winding single battery core, the single battery core includes a negative electrode sheet, a positive electrode sheet, a first separator and a second separator and is stacked in the order of the first separator, the negative electrode sheet, the second separator, and the positive electrode sheet, and the positive electrode sheet In the innermost layer, winding is made;

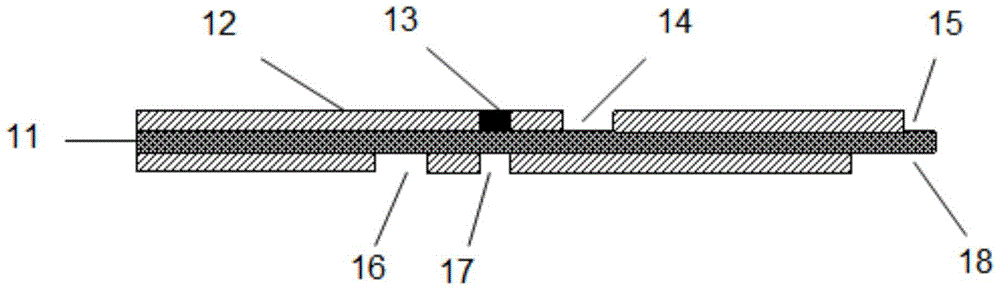

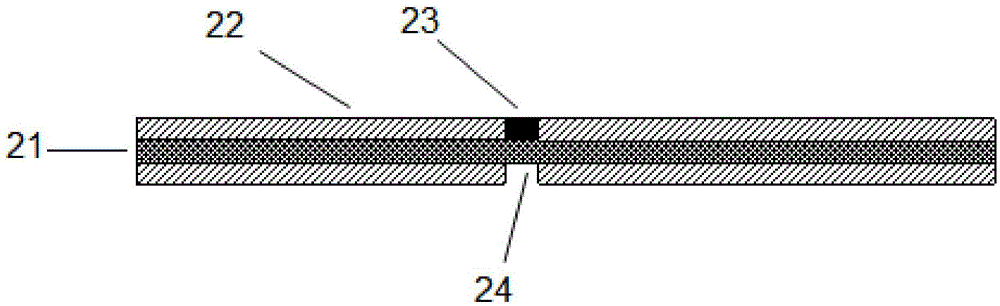

[0064] When the single battery cell is unfolded, the positive pole piece includes a positive pole piece strip 11, and positive active materials 12 are uniformly arranged on both sides of the positive pole piece strip 11, and one side of the positive pole piece strip 11 is provided with Positive electrode lug 13, positive first island region 14 and positive first blank region 15, the other side of the positive electrode strip 11 is provided with positive second island region 16, positive second blank region 17 and positive third Blank area 18; the positive pol...

Embodiment 2

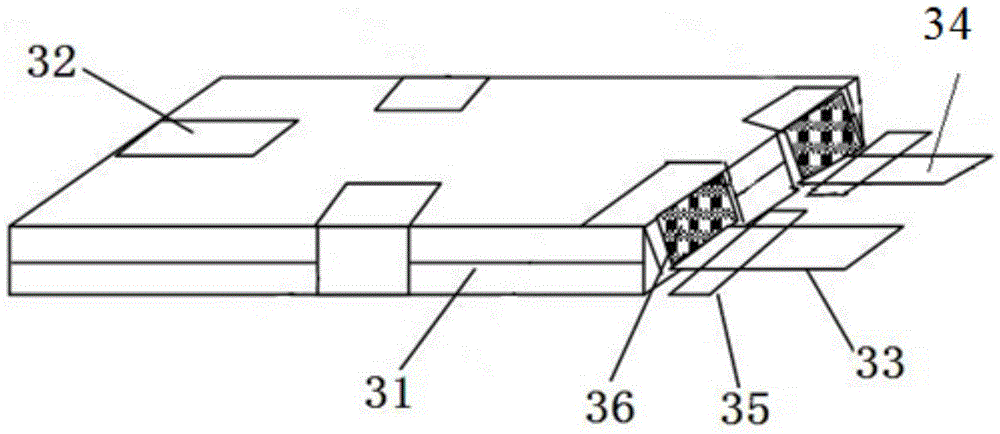

[0077] Embodiment 2, composite lithium-ion batteries

[0078] The cell prepared in this example is obtained by connecting two wound single cells prepared in Example 1 in parallel, and the tabs are placed in the order of "left positive, right negative" when connected in parallel, and the capacity after parallel connection is 10Ah.

Embodiment 3

[0079] Embodiment 3, Winding single cell

[0080] Winding single battery core as described in embodiment 1, the difference is:

[0081] The distance between the first positive island 14 and the positive tab 13 is 270 mm, and the distance between the second positive island 16 and the second blank area 17 is 270 mm;

[0082] The width of the positive pole tab 13 and the negative pole tab 23 are both 70 mm, and the thickness is 0.2 mm;

[0083]The widths of the positive first island region 14 and the positive second island region 16 are both 80mm;

[0084] The width of the positive first blank area 15 is 220 mm, and the width of the positive third blank area 18 is 620 mm;

[0085] The widths of the positive second blank area 17 and the negative blank area 24 are both 75mm;

[0086] The negative electrode tab 23 is made of copper;

[0087] The surface density of the positive electrode active material 12 on the positive electrode strip 11 is 210 mg / cm 2 , the surface density o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com