Ultra-low-speed high-torque motor and crane using this motor

A high-torque, ultra-low-speed technology, applied in the field of ultra-low-speed and high-torque motors, can solve problems such as temperature rise, increased vibration and noise, high production costs and maintenance costs, and achieve the effect of high torque output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

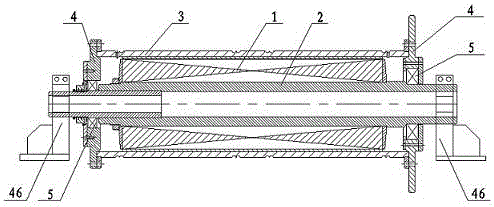

[0095] For example, the ventilation and heat dissipation in the motor can be carried out through the cooling air duct outside the stator and the cooling air duct inside the stator. In this case, the two end uniform pressure air gaps 12 should be connected to their respective ventilation ducts 14. The ventilation air ducts can be opened on the fixed disks at the corresponding ends and connected with the end equalizing air gap belts at the corresponding ends (see Figure 7 ) to simplify the structure, reduce wind resistance and improve efficiency, the ventilation duct on one fixed disk (such as the fixed disk on the right end) is used as an air intake duct, and the ventilation air on the other fixed disk (such as the fixed disk on the left end) The duct is used as an air duct. When forced ventilation is required, the ventilation duct on at least one of the fixed disks is provided with a forced ventilation device. The heat dissipation air duct in the stator and the heat dissipati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com