Method and system for automatically measuring aerobic respiratory capacity of biodegradable material

A biodegradable material and respiration technology, applied in the field of automatic determination of aerobic respiration of biodegradable materials, can solve problems such as large differences and inability to copy, reduce test errors, high repeatability, and realize real-time online monitoring. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

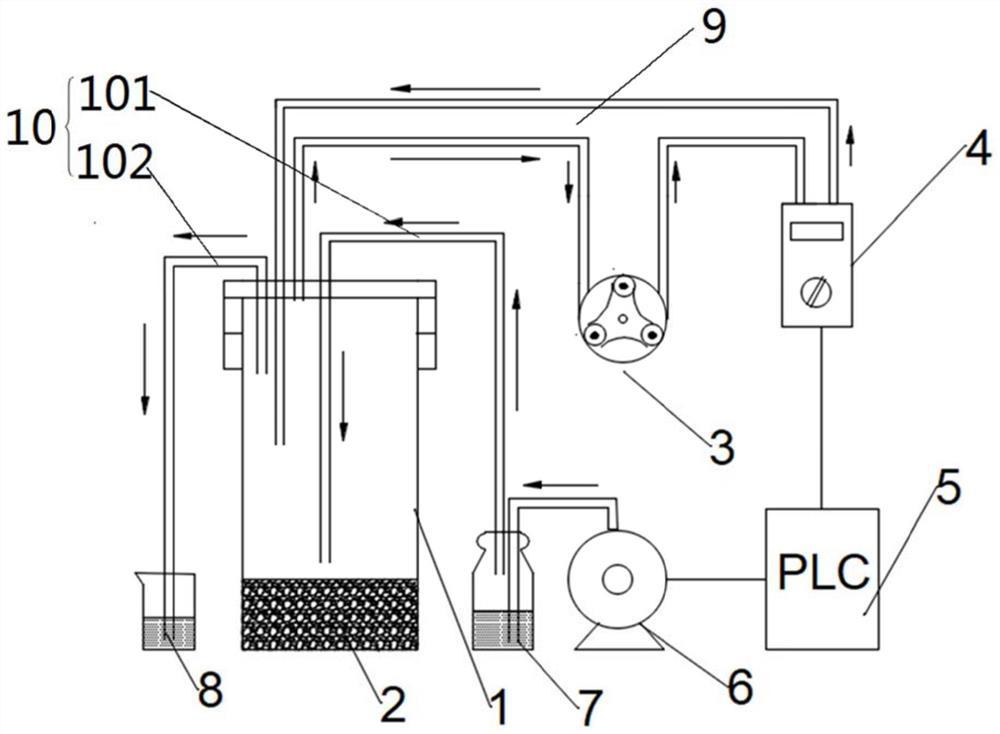

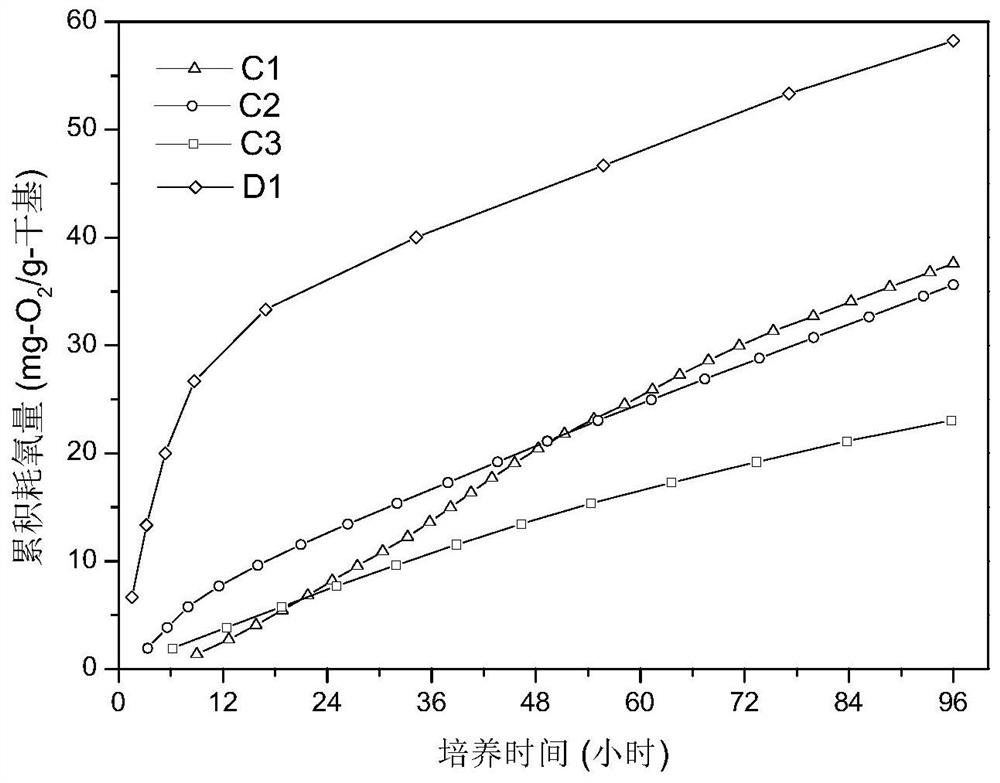

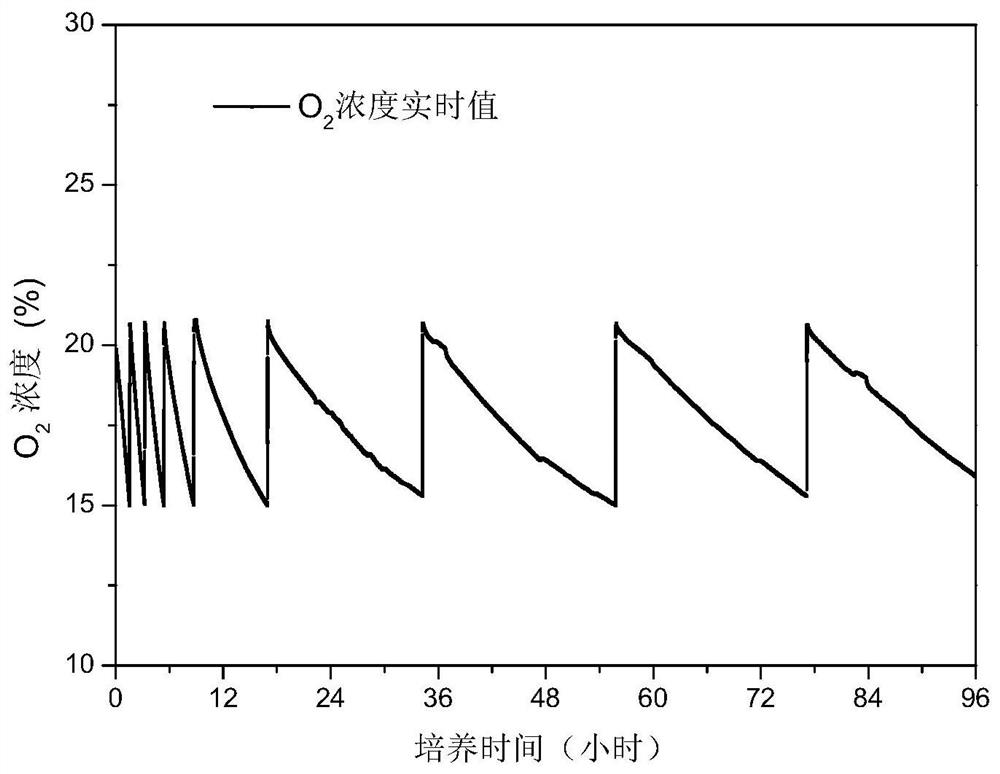

Embodiment 1

[0083] Take the compost produced by the kitchen waste mechanical composting reactor and record it as C1. Adjust the moisture content of the compost to 50%, inject 300 g of compost with the adjusted moisture content into the culture bottle, and place the culture bottle in an incubator at 20° C. for cultivation. Set the upper limit of oxygen concentration to 20.7%, and the lower limit of oxygen concentration to 18%. Start the PLC controller 5 to control the oxygen concentration and record data. Compost aerobic respiration test system such as figure 1 shown. After 96 hours of cultivation, the amount of oxygen consumed by the C1 reactor was 37.6mg-O 2 / g-dry basis, the cumulative oxygen consumption changes with time as figure 2 shown. Repeat the test twice by the same operation, the amount of oxygen consumed by the material in 96 hours is 37.9mg-O 2 / g-dry basis and 36.5mg-O 2 / g - dry basis. The test results are highly repeatable.

Embodiment 2

[0085] Take the compost produced by the sunshine composting house in rural areas, and record it as C2. Adjust the moisture content of the compost to 50%, inject 40 g of compost with the adjusted moisture content into the culture bottle, and place the culture bottle in an incubator at 20° C. for cultivation. Set the upper limit of oxygen concentration to 20.5%, and the lower limit of oxygen concentration to 18%. Start the PLC controller 5 to control the oxygen concentration and record data. Compost aerobic respiration test system such as figure 1 shown. After 96 hours of cultivation, the amount of oxygen consumed by the C2 reactor was 35.6 mg-O 2 / g-dry basis, the cumulative oxygen consumption changes with time as figure 2 shown.

Embodiment 3

[0087] Take the compost product that has undergone secondary fermentation and decompose, and record it as C3. Adjust the moisture content of the compost to 50%, inject 40 g of compost with the adjusted moisture content into the culture bottle, and place the culture bottle in an incubator at 20° C. for cultivation. Set the upper limit of oxygen concentration to 20.5%, and the lower limit of oxygen concentration to 18%. Start the PLC controller 5 to control the oxygen concentration and record data. Compost aerobic respiration test system such as figure 1 shown. After 96 hours of cultivation, the amount of oxygen consumed by the C3 reactor was 23.0mg-O 2 / g-dry basis, the cumulative oxygen consumption changes with time as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com