Top plug-in type spray gun for ventilating and slag gathering and preparation method thereof

A plug-in spray gun technology, which is applied to the top plug-in spray gun for air-permeable slag gathering in the molten iron pretreatment and slag removal process and its preparation field, can solve the problems of optimization of spray gun structure parameters and unexplainable problems, and achieve the improvement of comprehensive integrity and resistance The effect of mechanical damage ability, convenient layout, and reduced production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

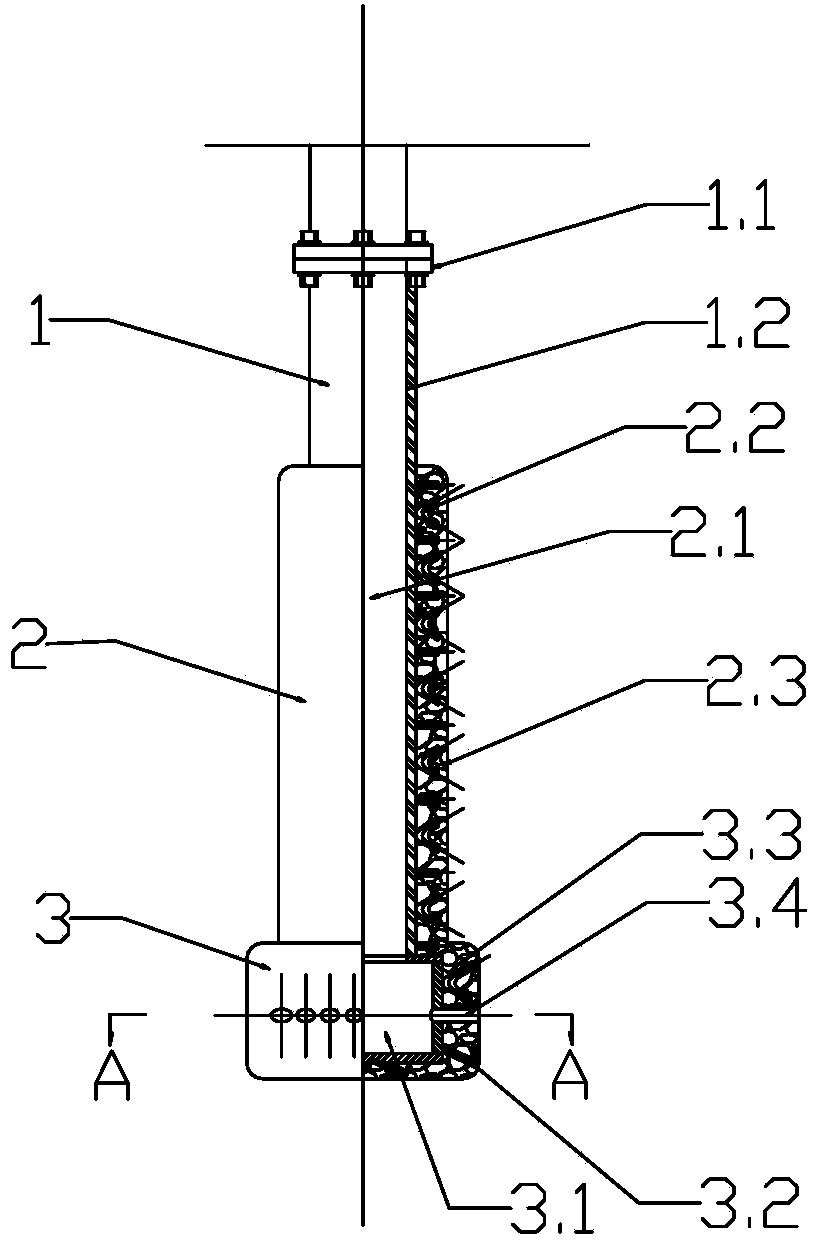

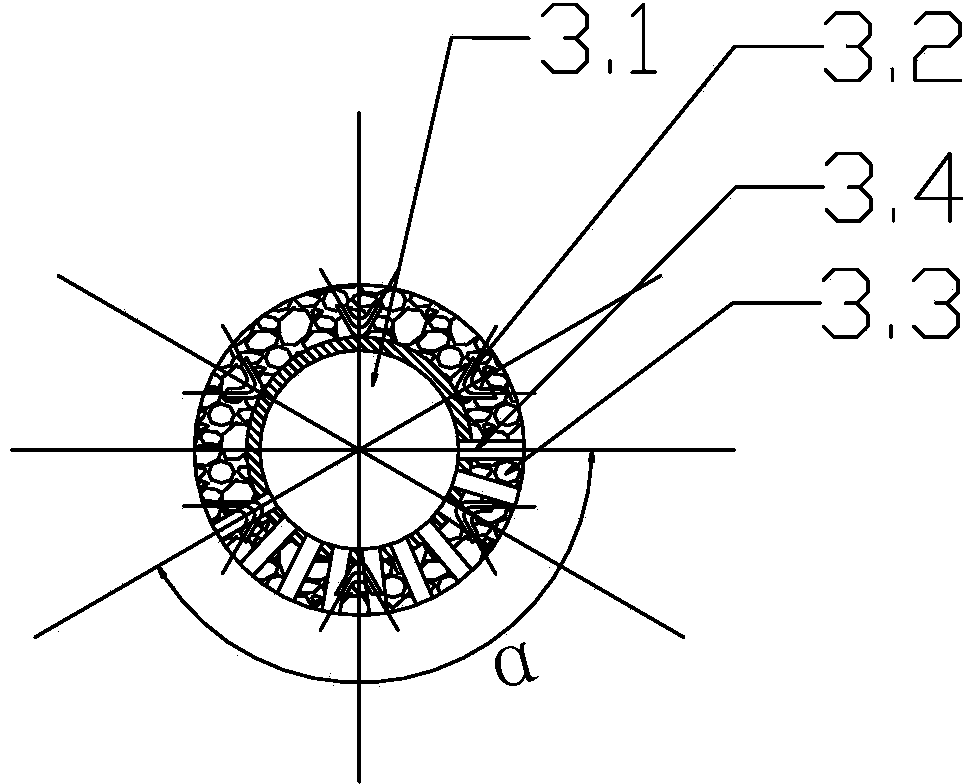

[0033] Such as Figure 1~2 As shown, a top-inserted spray gun for air-permeable slag accumulation includes a connecting section 1, a gun body section 2, and an injection section 3 connected in sequence, and the axial cross-sectional size of the injection section 3 is larger than that of the gun body section 2. It consists of a flange 1.1 and a connecting pipe 1.2; the gun body section 2 is composed of a gun body section supervisor 2.1, a gun body section V-shaped anchor 2.2 and a gun body section refractory castable lining 2.3; the spray section 3 is composed of a nozzle with a closed end. The air chamber 3.1 in the blowing section, the V-shaped anchor 3.2 in the blowing section and the refractory castable lining 3.3 in the blowing section,

[0034] The gun body section supervisor 2.1 is an ordinary carbon steel seamless pipe, wherein one end is welded to communicate with the flange 1.1, and the other end is welded to communicate with the blowing section air chamber 3.1. The ...

Embodiment 2

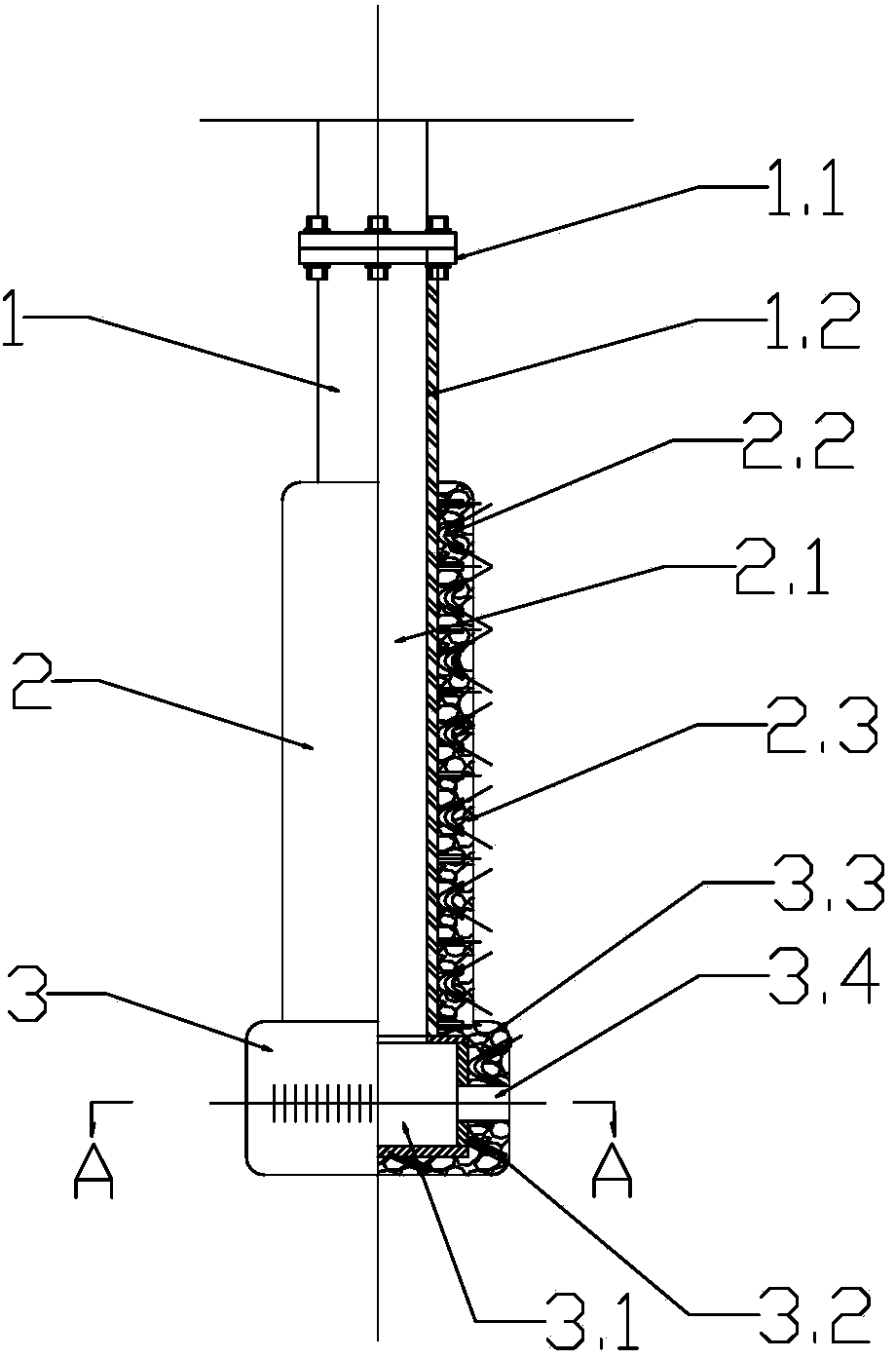

[0046] Such as Figure 3-4 As shown, a top-inserted spray gun for air-permeable slag accumulation, this embodiment is basically the same as Embodiment 1, the difference is:

[0047] The diffuse nozzle 3.4 has a slit structure, and the injection section 3 is an elliptical cylinder whose upper and lower edges are arc transition surfaces.

Embodiment 3

[0049] Such as Figure 5 As shown, a top-inserted spray gun for air-permeable slag accumulation, this embodiment is basically the same as Embodiment 1, the difference is:

[0050] The diffuse nozzle 3.4 has a capillary structure, and is arranged along the circumferential direction of the metal gas chamber 3 with an upward inclination of 10°. The injection section 3 is a round platform with a circular arc transition surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com