Remote control dedusting system of textile workshop

A dust removal system and remote control technology, applied in the textile industry, can solve the problems of high energy consumption, premature cleaning, lint, dust cleaning, etc., and achieve the effect of simplifying the operation process, wide monitoring range, and good dust removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

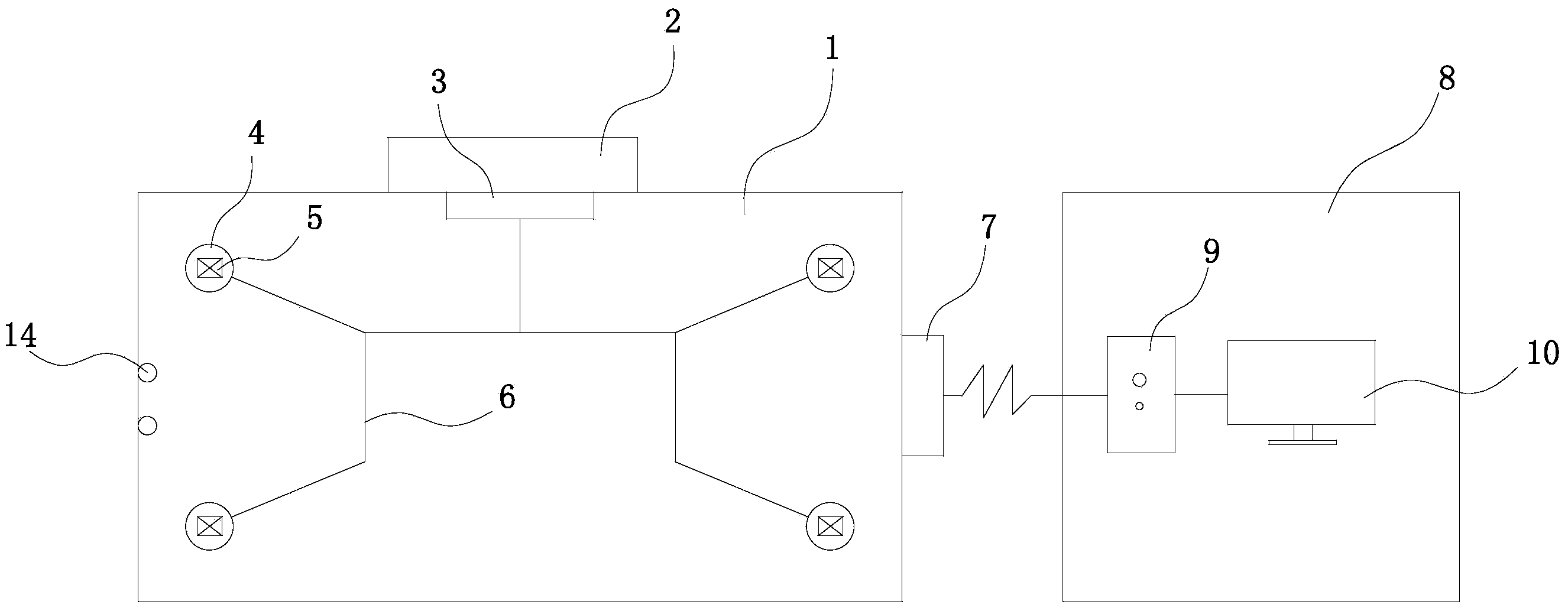

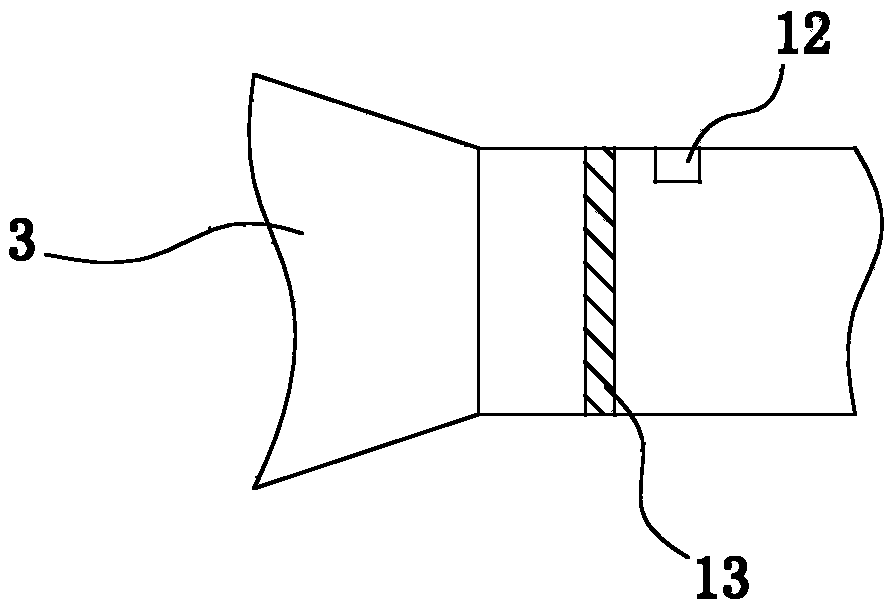

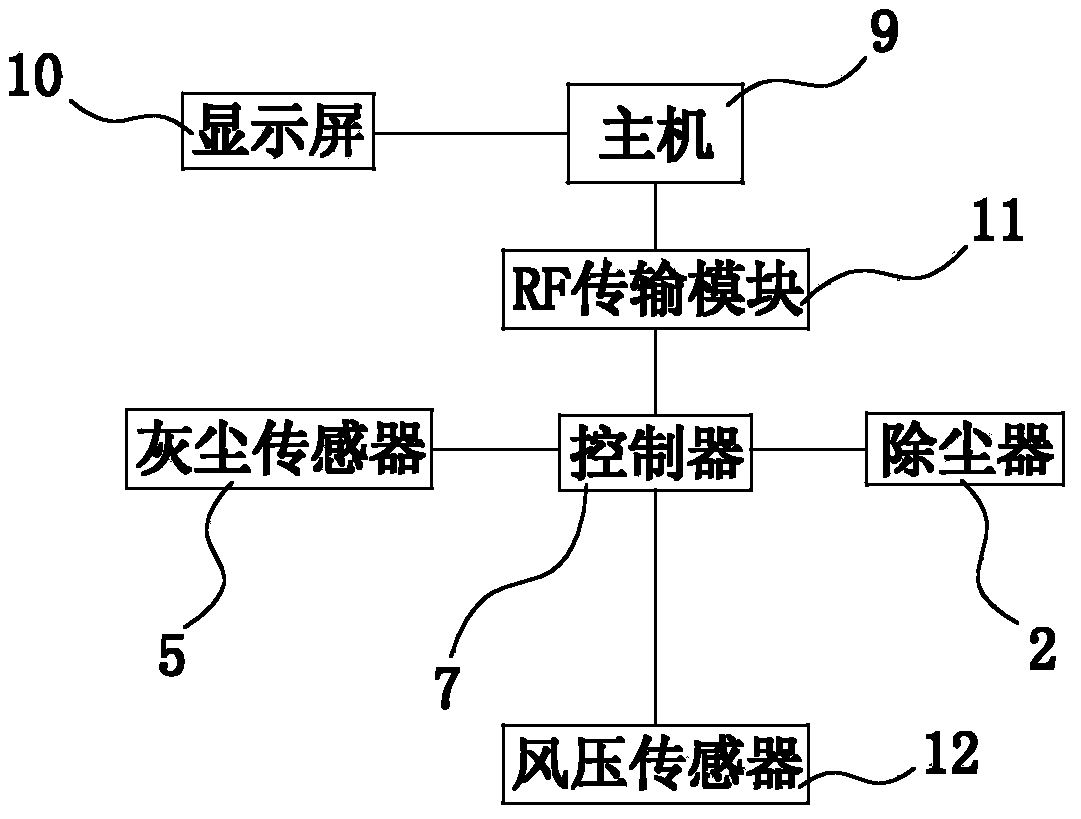

[0016] See figure 1 , figure 2 and image 3 , the remote control dedusting system of the textile workshop of the present embodiment, the system includes a dust collector 2 installed outside the textile workshop 1, and the air ducts 6 of the dust collector 2 are dispersedly installed on the ceiling of the textile workshop 1, and a plurality of air ducts 6 converge Finally, it is connected to the dust collector 2 through the air collection chamber 3; the ends of the air duct 6 are respectively equipped with an air collection port 4 and a dust sensor 5, and a filter plate 13 is installed in the air duct 6 between the air collection chamber 3 and the dust collector 2, A wind pressure sensor 12 is installed on the side of the filter plate 13 located in the direction of the dust collector 2; an indicator light 14 is installed on the inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com