Experimental device for simulating influence mechanism to flame structure flow field characteristics of bottom cross wind

A technology of flame structure and flow field characteristics, which is applied in the field of experimental test equipment for disaster combustion, and can solve problems such as inability to measure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

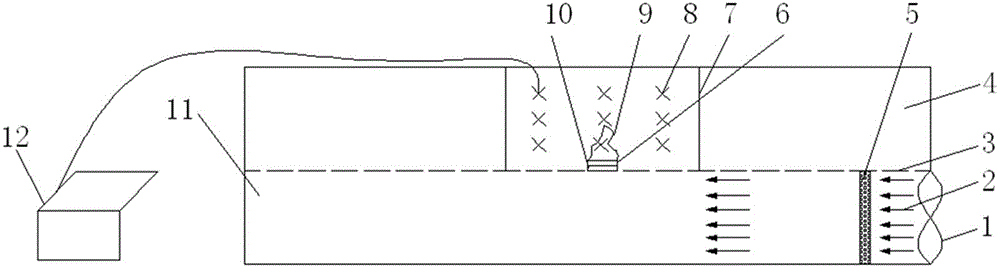

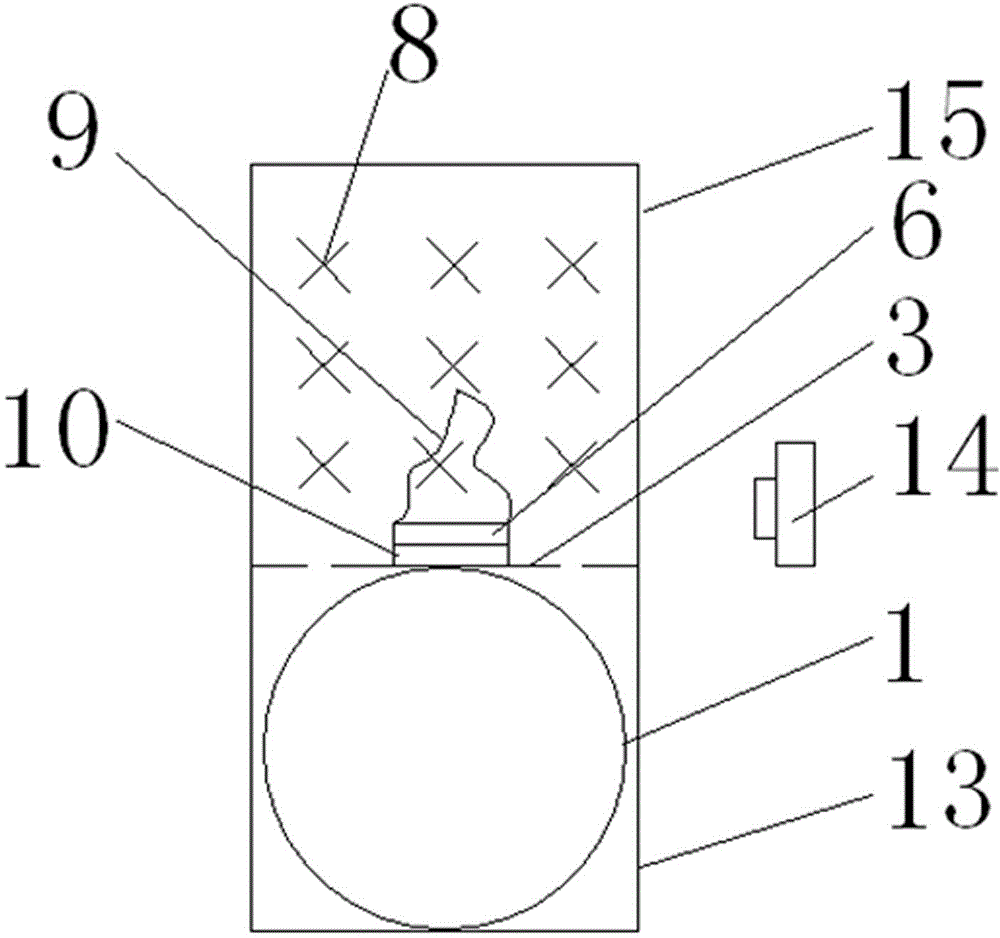

[0017] Such as figure 1 and 2 As shown, the experimental device for simulating the influence mechanism of the bottom transverse wind on the flame structure and flow field characteristics of the present invention includes a combustion box 4, a wind tunnel system 11 and a measurement and control system 12; the size of the combustion box 4 is 5m × 0.5 m×0.5m, the bottom is an open structure, and a hollow stainless steel tube 3 with a length of 5m, a diameter of 2cm, and a thickness of 1mm is set every 10cm. In order to facilitate the observation of the flame structure and the flow field characteristics of the smoke plume in the experiment, One side is an observation window 15, which is made of fire-resistant glass with a thickness of 5mm. The middle part of the wall corresponding to the observation window 15 is the operation port 7, and the size of the operation port 7 is 0.5m×1m. The size of the end is 2m, and it is made of quartz heat insulation board with a thickness of 8mm, ...

Embodiment 2

[0020] In this embodiment, the fire source 9 and the electronic balance 10 are placed on the end of the combustion box 4 away from the fan, and the wind speed test device 8 is correspondingly arranged at every 0.1m on the top of the fire source 9 oil pool 6, and other settings are the same as those in Embodiment 1. The same; this embodiment can simulate the law of the influence of the bottom wind on the upper flame structure and plume flow field characteristics when the fire source is located on the side and wall away from the fan.

Embodiment 3

[0022] In the present embodiment, a quartz heat shield with a thickness of 2 mm and a width of 0.1 m is placed in the middle of the hollow stainless steel pipe 3 at the bottom of the combustion box 4, and the electronic balance 10 is placed on the quartz heat shield, and other settings are the same as in Embodiment 1; In this embodiment, when there is an obstacle between the wind tunnel system 11 and the combustion box 4, the influence of the bottom wind on the upper flame structure and plume flow field characteristics can be simulated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com