Component distribution method for automobile seat framework

A technology of car seat frame and distribution method, which is applied in the field of component distribution of car seat frame, can solve the problem that the design structure depends on the experience and subjective judgment of designers, and achieves the effects of good economy, avoiding errors and reducing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

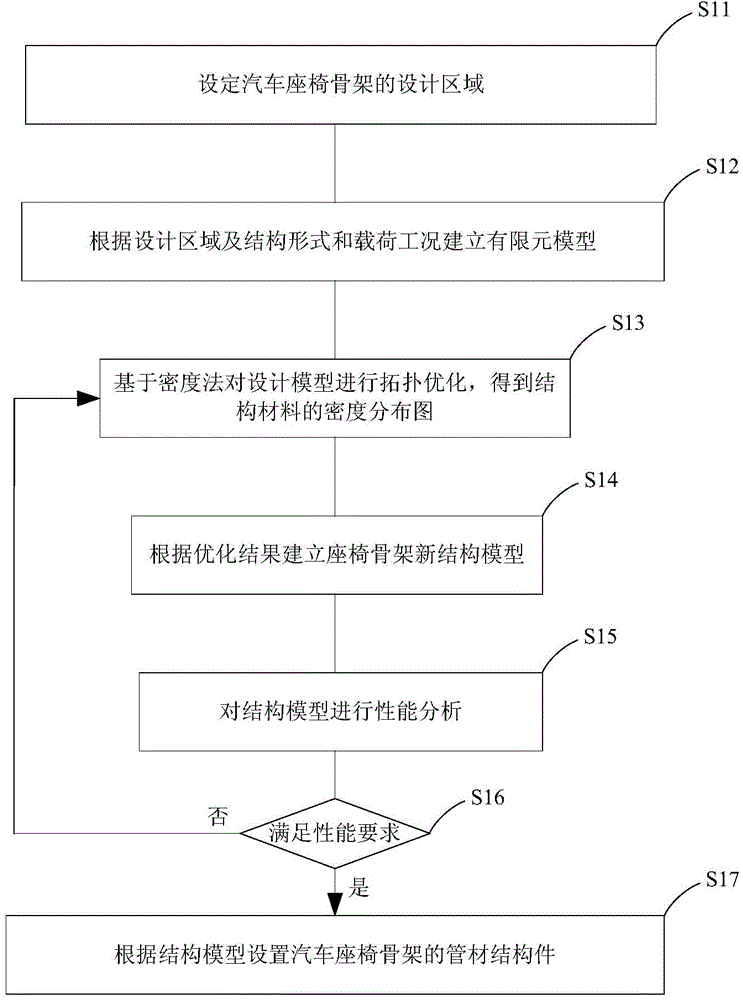

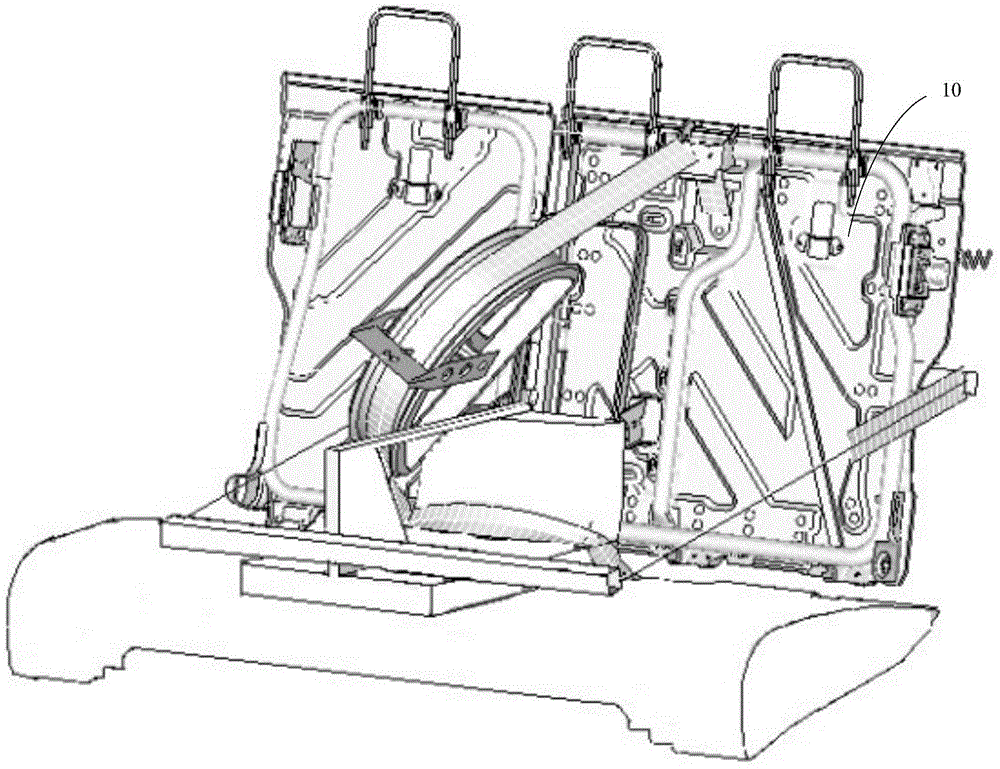

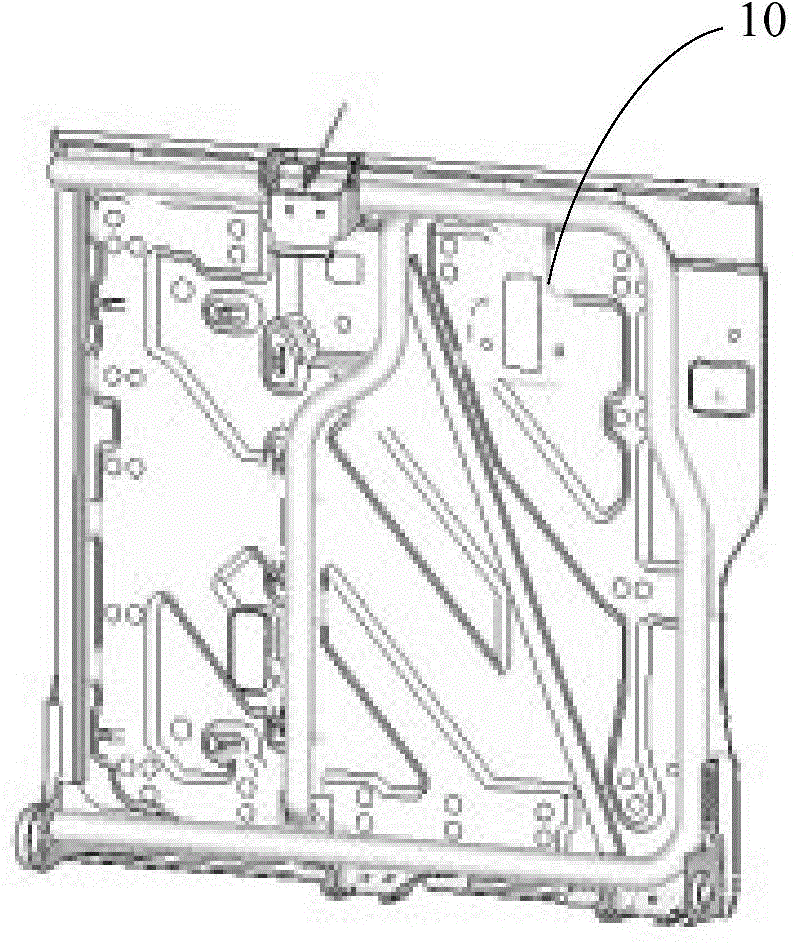

[0027] refer to figure 1 , shows the flowchart of the component distribution method of the car seat frame of the present invention. The invention provides a component distribution method of a car seat frame, selects a design area in the original model of the car seat frame, establishes a reasonable finite element model for the selected design area, and adopts the variable density method to analyze the finite element The topology optimization of the model is carried out to obtain the material density distribution map when the structural material volume is smaller than the original structure and the structural stiffness is the largest, and then the pipe structural parts are arranged according to the material density distribution map. According to the material properties of the seat frame, a new finite element model is established, and the mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com