Isolation structure of a high-voltage driving circuit and its preparation method

A high-voltage driving circuit and isolation structure technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problems of isolation structure breakdown voltage drop, breakdown, etc., and achieve simple preparation, ensure withstand voltage, and suppress punch-through Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

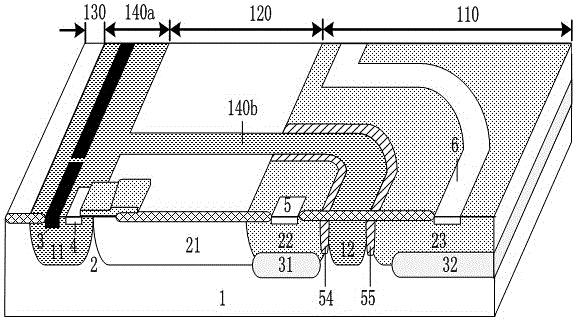

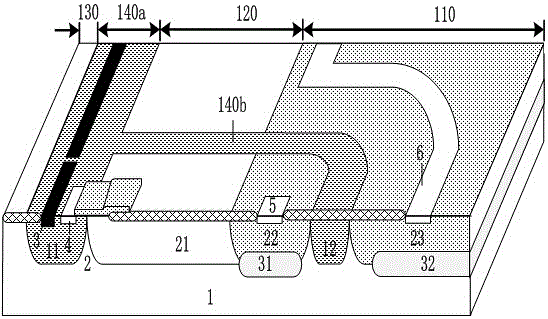

[0027] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

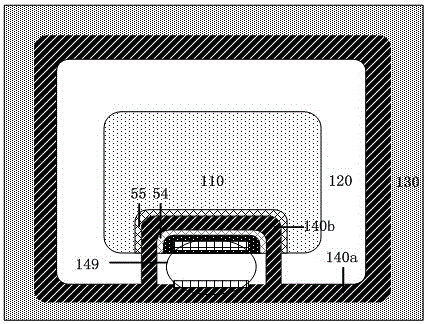

[0028] Such as figure 1 The structural representation of the present invention shown and figure 2The shown lateral cross-sectional view of the present invention is an isolation structure of a high-voltage driving circuit, including a P-type substrate 1 and a P-type epitaxial layer 2 arranged on the upper surface of the P-type substrate 1, the P-type substrate 1 and the P-type A first N-type buried layer 31 and a second N-type buried layer 32 are respectively provided at the junction of the epitaxial layer 2 . The P-type epitaxial layer 2 is provided with a low-voltage region 130, a first P-type well region 11, a second P-type well region 12, a first N-type well region 21, a second N-type well region 22 and a third N-type well region. well region 23 . The low-voltage region 130 is arranged for a circle along the edge of the P-type epitax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com