Substrate Integrated Waveguide Bandpass Filter

A substrate-integrated waveguide and band-pass filter technology, which is applied to waveguide devices, electrical components, circuits, etc., can solve the problems of unusable and large filter insertion loss, so as to reduce insertion loss and avoid processing technology Restrictions, avoiding the effect of processing technology restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

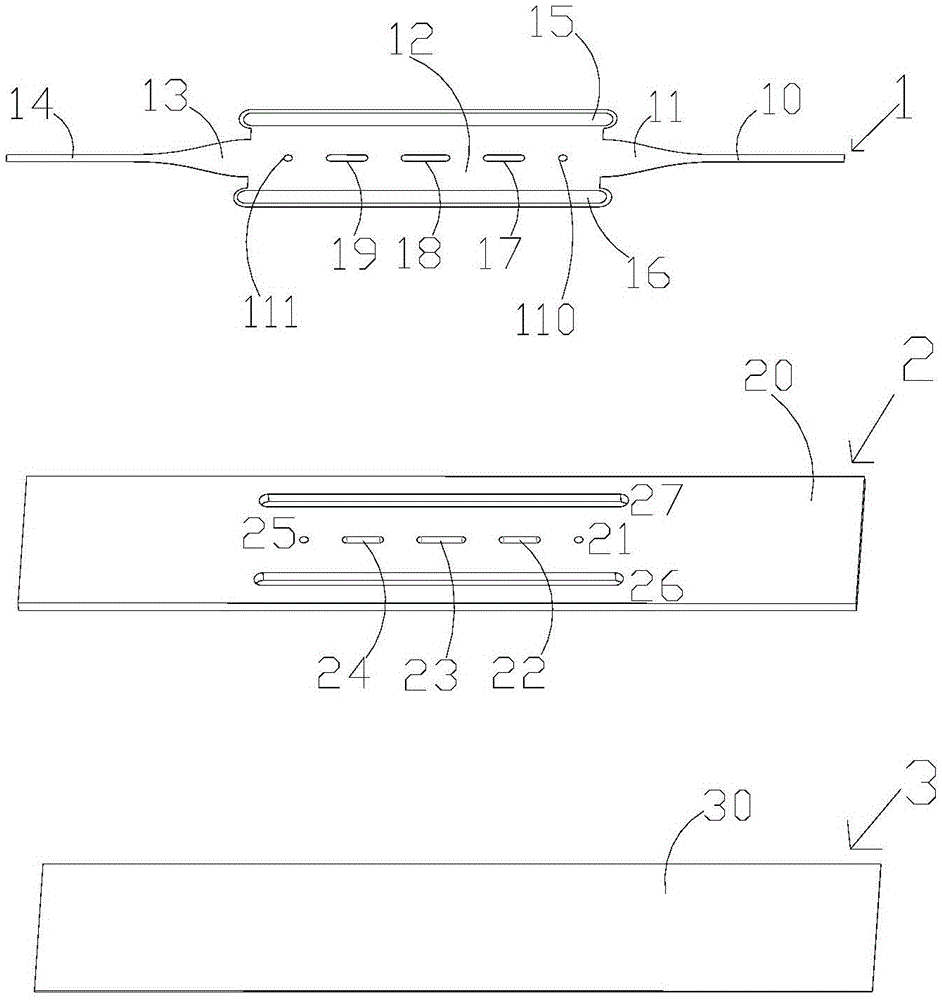

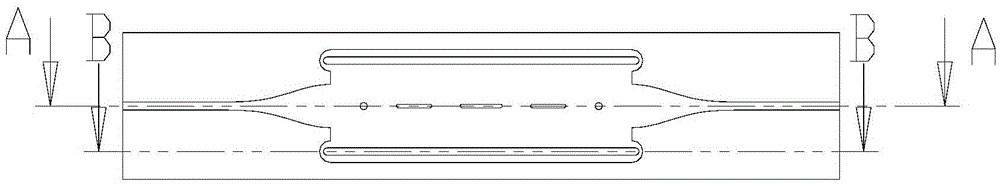

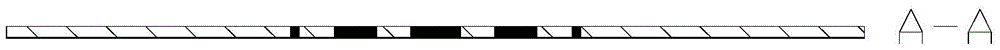

[0014] Such as figure 1As shown, it is a schematic exploded view of the three-dimensional structure of the substrate-integrated waveguide bandpass filter of the present invention. It includes a first metal layer 1, a dielectric layer 2, and a second metal layer 3 stacked from top to bottom; the first metal layer 1 specifically includes a first transmission line main line 10, a second transmission main line 14, and a first gradual transition line 11 , the second gradient transition line 13 and the first metal plate 12, the first metal plate concrete 12 includes the first strip-shaped opening 15, the second strip-shaped opening 16, the third strip-shaped opening 17, the fourth strip-shaped opening Holes 18, fifth strip-shaped openings 19, first circular openings 110 and second circular openings 111; one end of the first gradual transition line 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com