Intensive radiator

A radiator, intensive technology, applied in the direction of electric solid device, semiconductor device, cooling/ventilation/heating transformation, etc., can solve the problems of low practicability, increased volume, equipment burden, etc., to extend the service life, increase Heat dissipation area, the effect of accelerating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

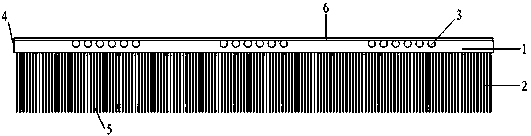

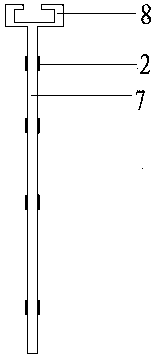

[0027] Install the radiator on the mechanical equipment, the radiator base 1 is fixedly connected with the equipment, the heat generated by the operation of the mechanical equipment is transferred to the radiator base 1 connected thereto, and the radiator base 1 transfers the heat to the heat sink 2 , the heat sink 2 dissipates heat; because the heat pipe 3 is buried in the base 1, the heat pipe 3 is a hollow pipe, and the heat transfer fluid is passed into the pipe, and the heat conduction layer 6 is laid outside the heat pipe 3, and the heat conduction layer 6 And the heat pipe 3 can effectively improve the thermal conductivity, so that the heat on the mechanical equipment can be transferred to the base 1 more quickly, and then the heat is transferred from the base 1 to the heat sink 2 for heat dissipation, effectively increasing the thermal conductivity by 25%, and improving the heat dissipation of the radiator The efficiency is 30%, and the beneficial effect is obvious.

Embodiment 2

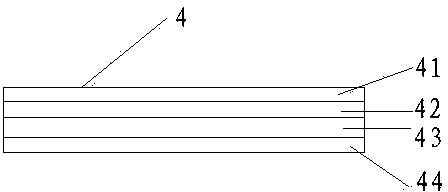

[0029] The surface layer of the radiator is provided with a protective layer 4; the present invention increases the protective layer 4 on the surface layer of the radiator, and the protective layer 4 includes an anti-scratch layer 41, a heat conduction layer 42, a corrosion-resistant layer 43, and an installation glue in order from the outside to the inside. Layer 44; by adding a protective layer 4 on the surface of the radiator, it can effectively prevent the radiator from being in direct contact with the air, prevent the radiator 2 from being corroded by harmful substances in the air and cause damage, and effectively prolong the service life of the radiator 2 by 10%; and the protective layer 4 The added heat conduction layer 42 can further improve the thermal conductivity and heat dissipation efficiency.

Embodiment 3

[0031] The heat sink 2 of the intensive heat sink provided by the present invention is provided with a temperature sensor 5; the heat sink 2 is connected with the control system by communication, and the present invention can detect the working condition of the heat sink in real time by adding the temperature sensor 5, if the heat sink If the heat dissipation temperature of the radiator is within the set range, the control system controls the normal operation of the mechanical equipment; if the heat dissipation temperature of the radiator is found to exceed the set range, the temperature sensor 5 will feed back the over-temperature signal to the control system, and the control system will issue an over-temperature alarm notification The staff handles it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com