Automatic intelligent container paint mixing and conveying system and using method thereof

A conveying system and container technology, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of spraying the surface of the container, the labor intensity of the paint adjuster, and the scrapping of the whole barrel of paint, so as to avoid losses and accidents, reduce labor intensity, The effect of preventing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

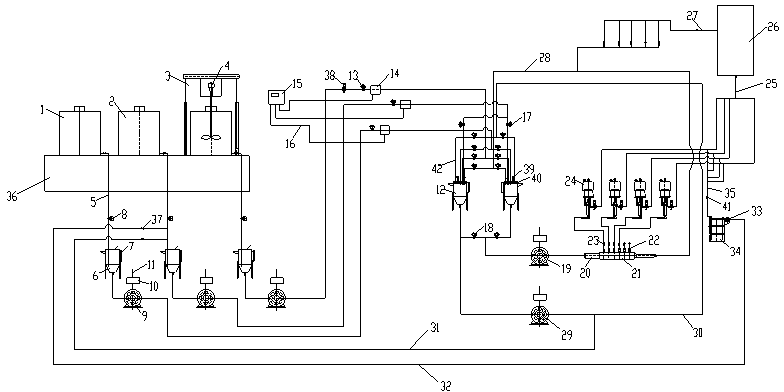

[0028] Paint delivery and automatic intelligent paint mixing system for zinc-rich primer:

[0029] refer to figure 1 As shown, the paint conveying mechanism includes a crude paint bucket 3, a dilution solvent bucket 2 and a curing agent bucket 1, and the crude paint bucket 3, the dilution solvent bucket 2 and the curing agent bucket 1 are placed on the same paint storage rack 36, The agitator 4 with a lifting mechanism is provided in the raw paint bucket 3, which can be pre-stirred. The paint mixing bucket 12 is provided with a cleaning nozzle 40 and an electric agitator 39, and the cleaning nozzle 40 and the electric agitator 39 Located at the top cover position, the transition barrel 6 and the paint mixing barrel 12 are provided with upper and lower limit level gauges 7, and the upper and lower limit level gauges 7 are located on the right side of the transition barrel 6 and the paint mixing barrel 12, The first delivery pump, the second delivery pump and the third delivery...

Embodiment 2

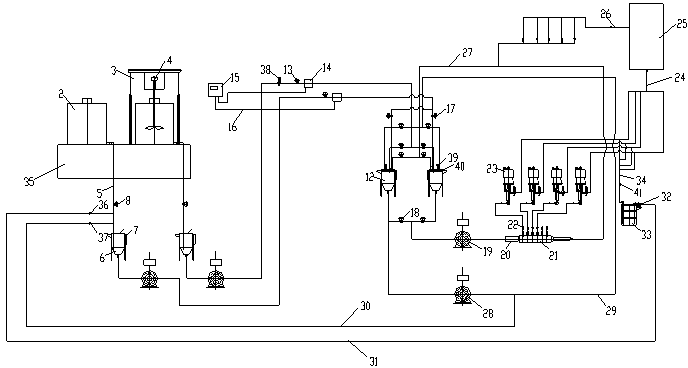

[0046] Paint conveying and automatic intelligent paint mixing system for top coat:

[0047] refer to figure 2 As shown, the paint conveying mechanism includes a raw paint bucket 3 and a diluted solvent bucket 2, and the raw paint bucket 3 and the diluted solvent bucket 2 are placed on the same paint storage rack 35.

[0048] A stirrer 4 with a lifting mechanism is provided in the raw paint bucket 3, which can be pre-stirred.

[0049] The paint mixing bucket 12 is provided with a cleaning nozzle 40 and an electric agitator 39, and the cleaning nozzle 40 and the electric agitator 39 are located on the top cover.

[0050] Both the transition barrel 6 and the paint mixing barrel 12 are provided with upper and lower limit level gauges 7 , and the upper and lower limit level gauges 7 are located on the right side of the transition barrel 6 and the paint mixing barrel 12 .

[0051] Both the delivery pump 1 and the delivery pump 2 are provided with an electromagnetic air valve 10 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com