Working area scrap-proof system

A working area and anti-chip technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of reduced machine life, difficult operation, hidden safety hazards, etc., to achieve convenient maintenance or replacement, comfortable working environment , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

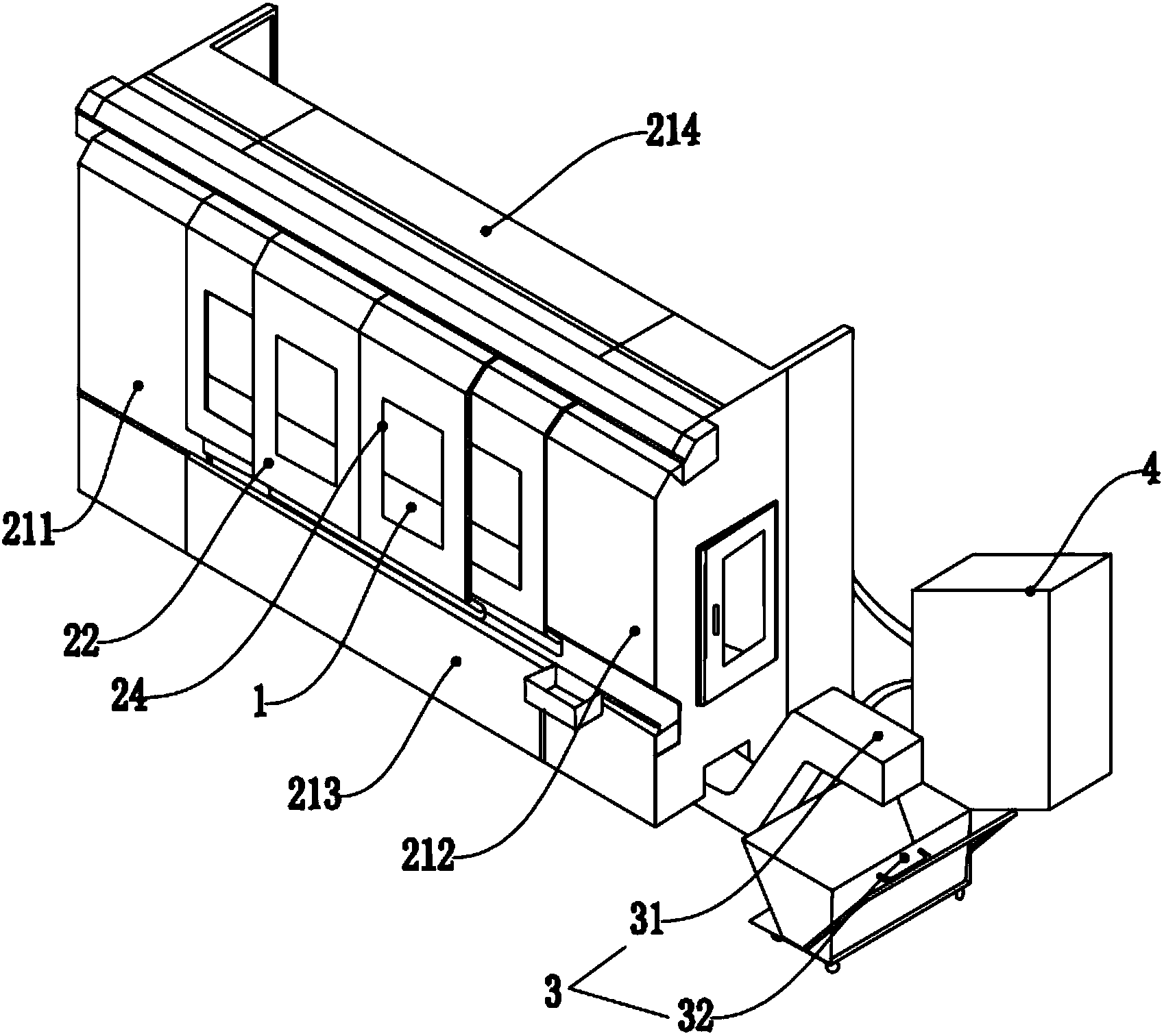

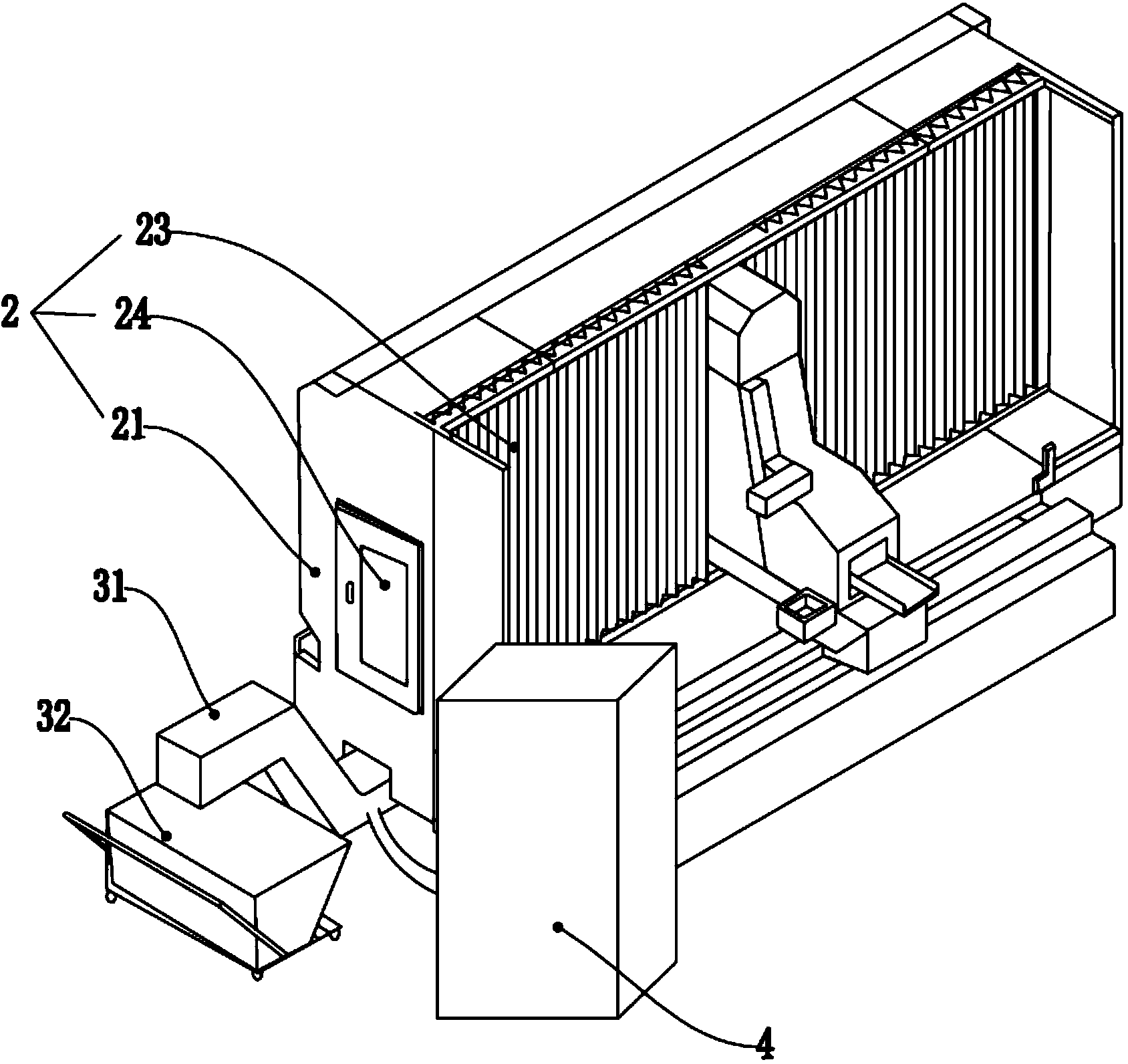

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0023] A working area anti-chip system, including a machine tool 1, a protective cover 2, a chip removal device 3 and a water circulation box 4, the protective cover 2 includes a baffle 21, a sliding door 22 and a retractable cover 23, the machine tool 1 The left and right sides, the front bottom and the top are surrounded by the baffle plate 21, the rear of the machine tool 1 is provided with the telescopic shield 23, and the top of the telescopic shield 23 is movably installed on the top of the machine tool 1. The baffle 21 directly above, the front of the machine tool 1 is provided with the sliding door 22, and the sliding door 22 is installed in front of the machining center of the machine tool 1 in cooperation with the baffle 21. 1. A closed space is formed by connecting and installing the baff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com