Torque distribution control method for electric-wheel automobile hub motor torque distribution system

An electric wheel vehicle, torque distribution technology, applied in electric vehicles, control drive, power management, etc., can solve problems such as low torque efficiency, optimal solution deviation, and no consideration of limit constraints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

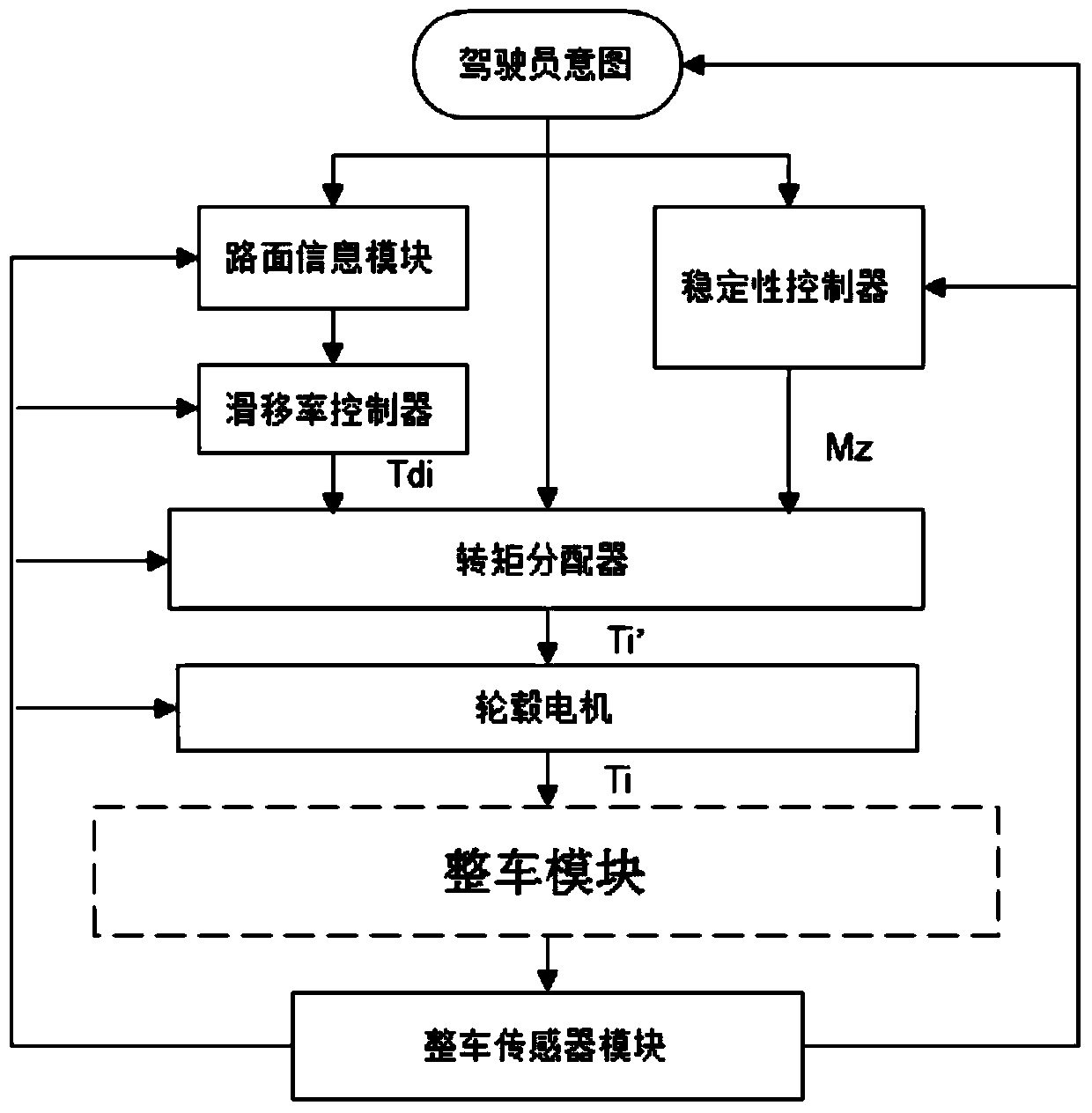

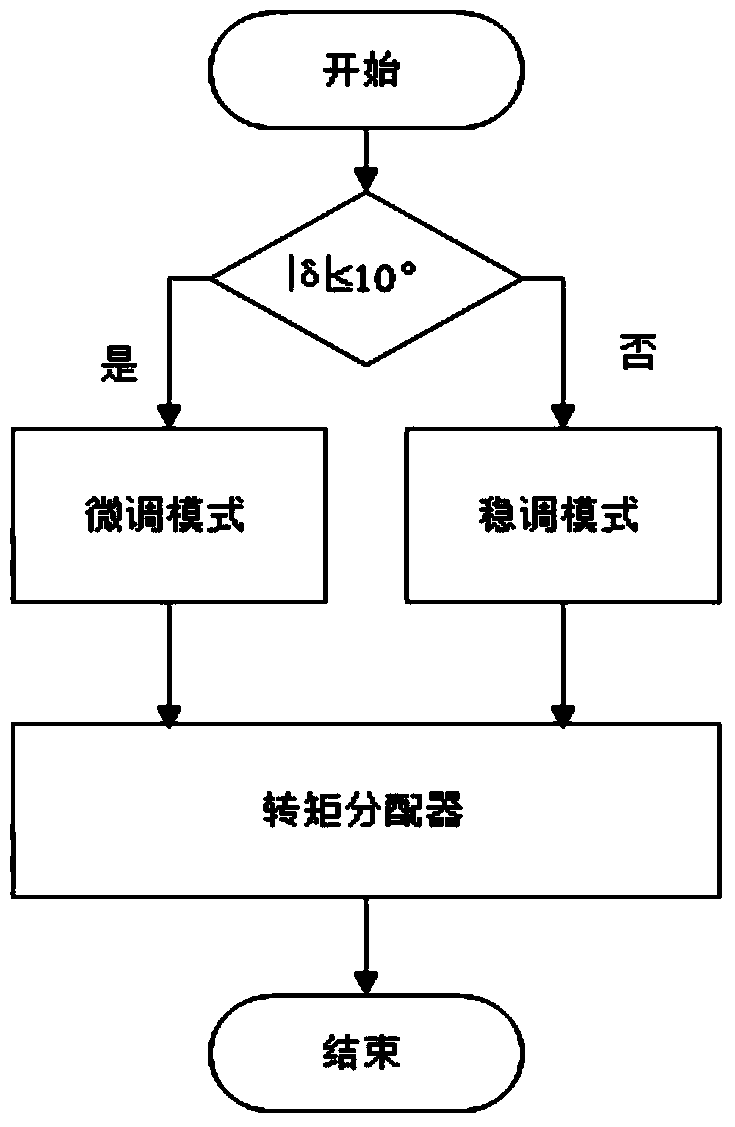

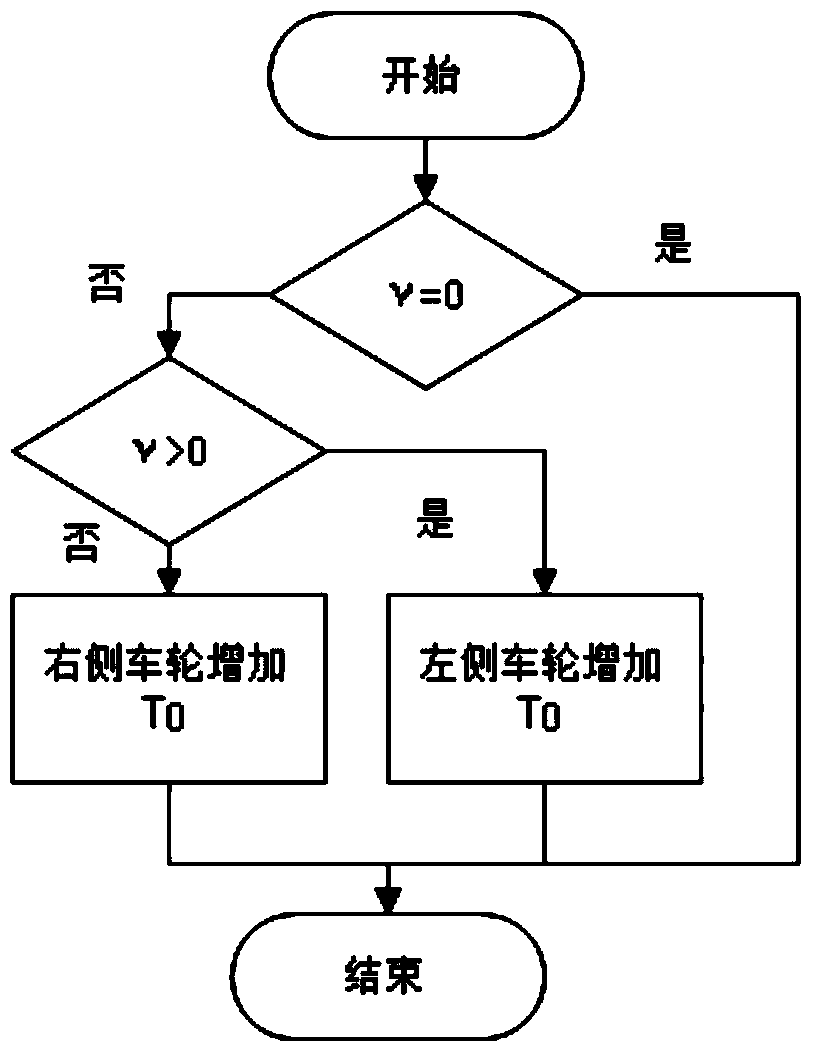

[0048] Please refer to figure 1 As shown, the electric wheel vehicle hub motor torque distribution system of the present invention includes a driver intention module, a hub motor, a stability controller, a torque distributor, a slip ratio controller, a vehicle module, a road surface information module and a sensor module. Stability controller includes vehicle fine-tuning mode and stable mode (including vehicle reference model and stability control algorithm); torque divider divides vehicle motion into power mode, economy mode and stability mode. The torque obtained in the stabilizer controller and slip ratio controller is distributed according to different working conditions to improve the driving ability of the car, the utilization efficiency of the motor and the stability of the whole vehicle when the car is running normally or when slipping occurs. Driver's steering wheel angle δ f The transmission ratio of the steering mechanism is converted into the front wheel angle δ. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com