Novel method for melting liquid glass by submerged combustion

A glass liquid and mixed combustion technology, which is applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problem that the mixed gas pressure and spray speed are greatly affected, the kiln refractory material is eroded quickly, and the service life of the kiln is reduced and other problems, to achieve the effect of adjustable and controllable combustion depth, stable and reliable combustion process, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

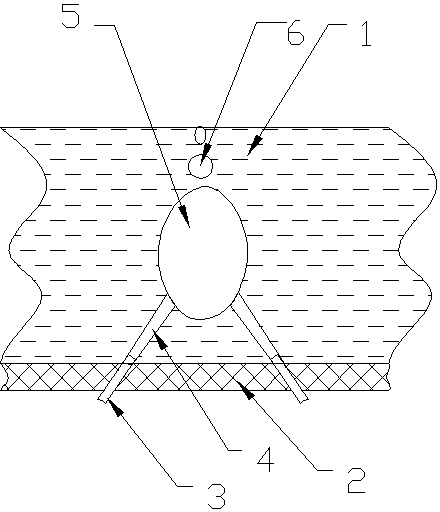

[0014] In the figure, the fluid oxidizer and the fluid fuel are respectively injected into the molten glass 1 through the fluid injector 3, the fluid oxidizer and the fluid fuel meet in the molten glass, mix and burn to form a combustion cavity, the generated high-temperature gas stirs the molten glass, and Most of the heat is transferred to the glass liquid and batch material, so that the glass material melts rapidly.

[0015] The above-mentioned fluid oxidant can adopt liquid ammonium nitrate, hydrogen peroxide, etc., and the fluid fuel can adopt kerosene, diesel oil, etc.

[0016] The ideal combustion effect can be achieved by adjusting the insertion depth of the fluid injector 3 in the molten glass 1 , or the distance and angle between the fluid burners of two different fluids, as well as the pressure and flow rate of the fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com