Continuous casting flow control refractory material and its application

A refractory material and continuous casting technology, applied in the field of refractory materials, can solve the problems of poor erosion resistance, increase the production cost of steel mills, and expensive functional parts, so as to improve chemical corrosion resistance, improve thermal shock stability, and reduce expansion. The effect of coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

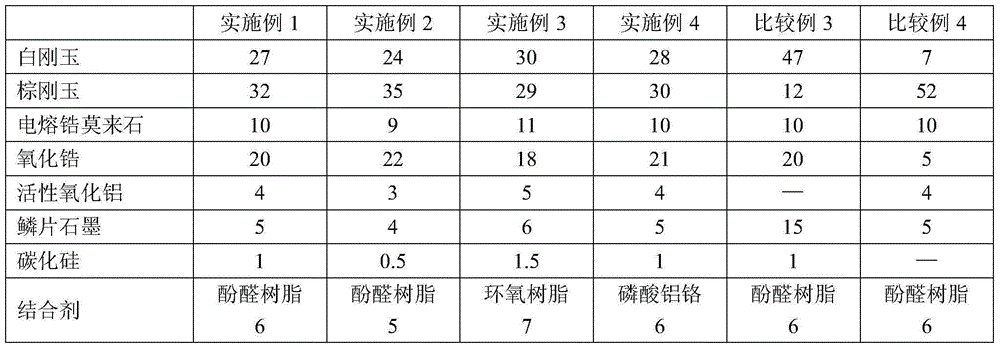

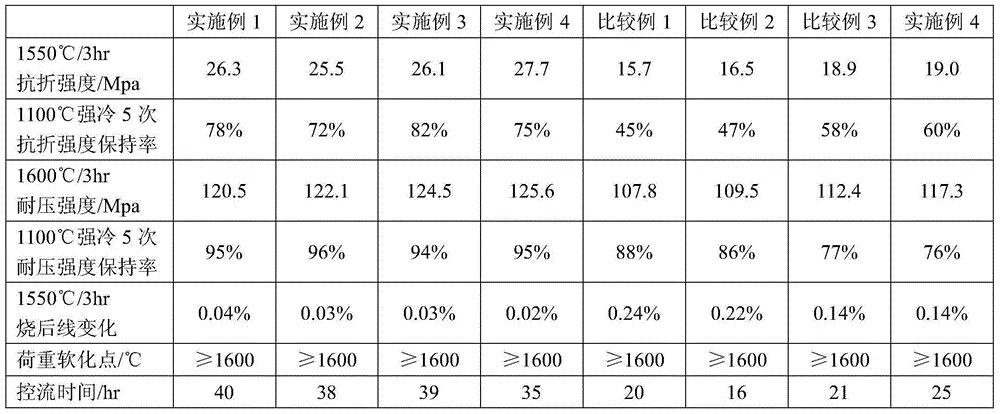

Embodiment 1

[0029] Example 1 The upper brick bowl

[0030] According to the formula ratio of Example 1 in Table 1, the raw materials and the adhesive are mixed together to make batch materials; the batch materials are fed into the mold, and press-molded to make the upper brick bowl; dry and harden after demoulding.

Embodiment 2

[0031] Embodiment 2 The upper brick bowl

[0032] The implementation process of this embodiment is basically the same as that of Example 1, and the adjustment of its formula is shown in Table 1 for details.

Embodiment 3

[0033] Example 3 long nozzle bowl

[0034] According to the formula ratio of embodiment 3 in table 1, the raw materials and the binder are mixed together to make batch materials; the batch materials are fed into the mold, and press-molded to make the upper brick bowl; dry and harden after demoulding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com