A kind of in-situ suspension polymerization method of graphene/nano calcium carbonate/vinyl chloride terpolymer resin

A technology of vinyl chloride ternary copolymer resin and nano-calcium carbonate, which is applied in the field of nano-materials, can solve problems such as difficult implementation, and achieve the effects of avoiding demulsification, improving performance, and having thermodynamic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

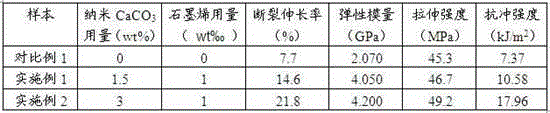

[0028] A kind of graphene / nanometer calcium carbonate / vinyl chloride ternary copolymerization resin in-situ suspension polymerization method, specifically comprises the following steps:

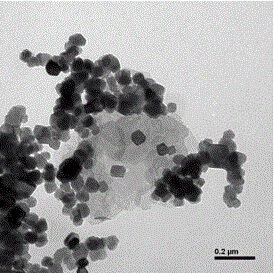

[0029]Step 1: Add 1000mL deionized water to the flask; add 3g of intercalation agent sodium lauryl sulfate, fully dissolve; add 5g of graphene, 75g of nano-calcium carbonate, stir and disperse for 15 minutes; put it into an ultrasonic processor for 15 minutes, Ultrasonic power 1000 watts; heat up to 70 °C, add 10 g of emulsified micellar protective agent n-hexadecyl alcohol; add 400 mL of hydroxypropyl methylcellulose ether aqueous solution with a concentration of 2%, stir well; More than 1000 watts, the processing time is 60 minutes, and the in-situ polymerization grade graphene / nano calcium carbonate microemulsion is obtained. Observation by transmission electron microscope, the figure 1 .

[0030] Step 2: In a 20L stainless steel reaction kettle, add 10kg of deionized water; start stirri...

Embodiment 2

[0033] A kind of graphene / nanometer calcium carbonate / vinyl chloride ternary copolymerization resin in-situ suspension polymerization method, specifically comprises the following steps:

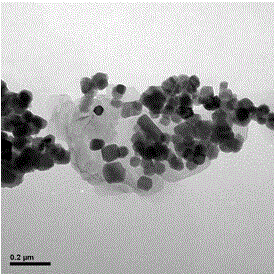

[0034] Step 1: Add 1000mL deionized water to the flask; add 10g of sodium dodecylbenzenesulfonate as an intercalation agent, and fully dissolve; add 5g of graphene and 150g of nano-calcium carbonate, stir and disperse for 15 minutes; put it into an ultrasonic processor for 30 Minutes, ultrasonic power 2000 watts; heat up to 70 degrees, add 20 g of emulsified micellar protective agent n-stearyl alcohol; add 400 mL of hydroxypropyl methylcellulose ether aqueous solution with a concentration of 2%, stir well; put it into an ultrasonic processor for processing, The ultrasonic power is 2000 watts, and the treatment time is 60 minutes to obtain in-situ polymerization grade graphene / nano-calcium carbonate microemulsion. Observation by transmission electron microscope, the figure 2 .

[0035] Step...

Embodiment 3

[0038] A kind of graphene / nanometer calcium carbonate / vinyl chloride ternary copolymerization resin in-situ suspension polymerization method, specifically comprises the following steps:

[0039] Step 1: Add 1000mL of deionized water to the flask; add 2g of sodium dodecyl sulfate and 8g of sodium dodecylbenzenesulfonate as intercalation agents, and fully dissolve; add 50g of graphene and 50g of nano calcium carbonate, stir and disperse for 15 minutes ; Put it into an ultrasonic processor for 15 minutes, with an ultrasonic power of 2000 watts; heat up to 70°C, add 30 g of emulsified micellar protective agent n-heptadecanol; add 400 mL of a 2% aqueous solution of hydroxypropyl methylcellulose ether, and stir thoroughly Put it into an ultrasonic processor for processing, the ultrasonic power is greater than 2000 watts, and the processing time is 60 minutes to obtain in-situ polymerization grade graphene / nano calcium carbonate microemulsion.

[0040] Step 2: In a 20L stainless stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com