A kind of long-acting bacteriostatic silicone rubber prosthetic material and preparation method thereof

A technology of antibacterial and silicone rubber, which is applied in the field of long-acting antibacterial composite silicone rubber prosthetic materials and its preparation, can solve the problems of short service life and susceptibility to bacteria, so as to restore the appearance and solve the problem of bacterial adhesion , high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

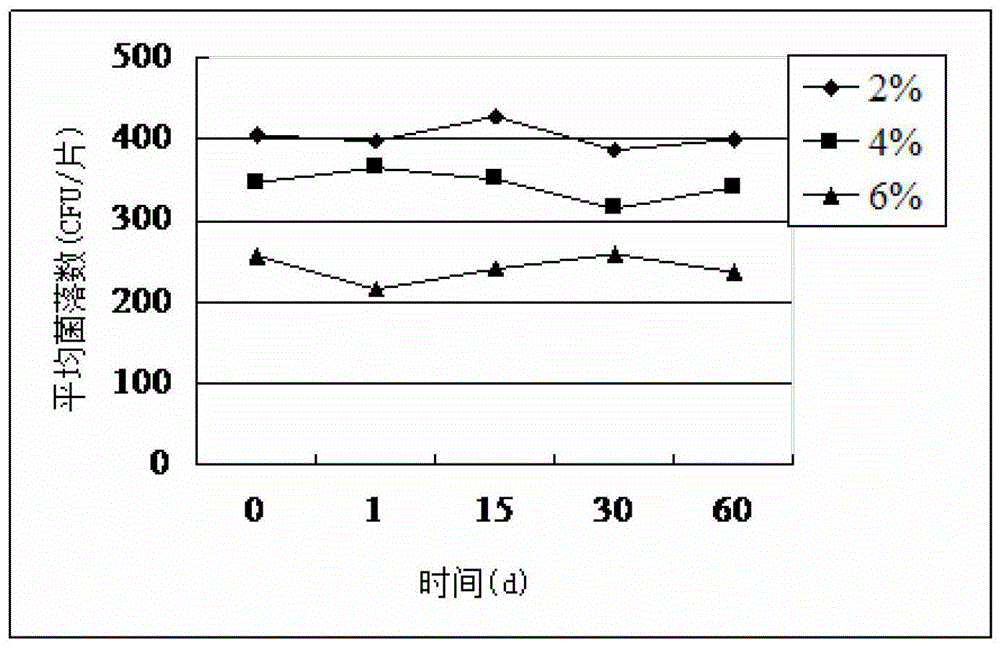

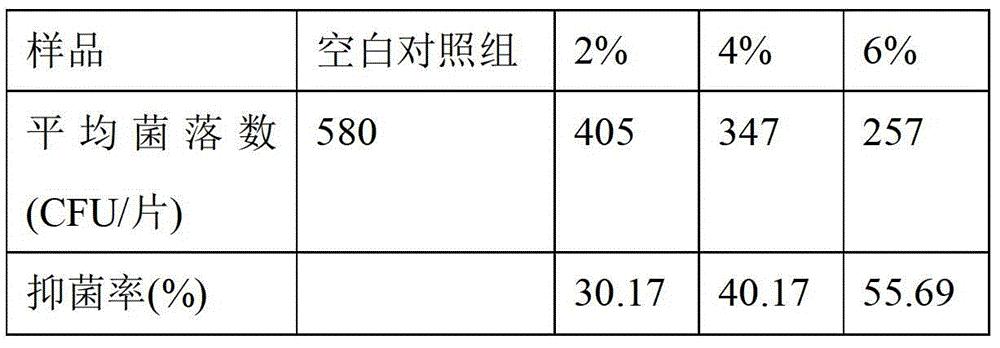

Image

Examples

Embodiment

[0020] 1) Mix 10ml of nitric acid with a volume ratio of 69-70% and 40ml of ethanol to form a solution A, add 6.8ml of tetrabutyl titanate drop by drop to the above solution A, and stir the mixed solution while adding to form a solution B. Stir for another 15 minutes to obtain a sol, dry at 35°C for 30 days to form a gel, and finally place it in a vacuum oven and bake at 300°C for 3 hours to obtain N-modified nano-titanium dioxide.

[0021] 2) Diluent (Q7-9180, Dow Corning, USA) and two-component medical silicone rubber (MDX4-4210, Dow Corning, USA) matrix (abbreviated as MB) at a ratio of 1:1 by magnetic stirring (HJ-6 , Tianjin Fuhua Electronic Instrument Co., Ltd.), mixed (10 minutes), improve the fluidity of silicone rubber, to obtain the first mixture.

[0022] The silicone rubber used in this example is the MDX4-4210 product of Dow Corning in the United States. It is a commonly used silicone rubber for maxillofacial repair. The main components of its matrix are dimethyls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com