High-strength steel for metallurgical saw blades and heat treatment method thereof

A heat treatment method and high-strength technology, applied in the direction of heat treatment furnace, heat treatment equipment, process efficiency improvement, etc., can solve the problems of shortened production process, uneven hardness, environmental pollution, etc., to achieve improved production efficiency, low cost, and improved work environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

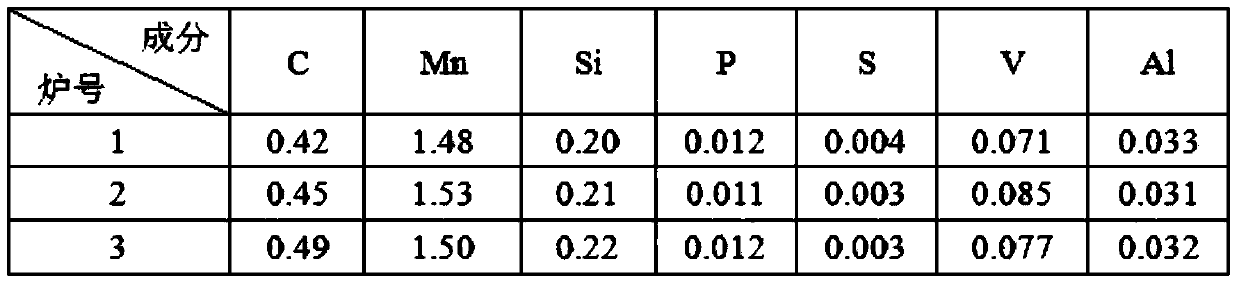

[0029] By adopting the chemical composition and production method of the present invention, 3 furnaces (3 batches) of metallurgical saw blade steel are produced. The chemical composition of the three heats of steel is shown in Table 1. The 3 furnaces of steel are smelted, continuously cast, and hot rolled into 15mm thick plates, and then heat treated. The heat treatment process parameters are shown in Table 2. After heat treatment, samples were taken from each batch of steel plates, and the mechanical properties of the samples were tested. The test results are shown in Table 3.

[0030] Table 1 The chemical composition (wt%) of the steel of the embodiment, the balance is Fe

[0031]

[0032] Table 2 The heat treatment parameters of the steel plate of the embodiment

[0033]

[0034] Table 3 Mechanical properties of the steel plates of the examples after heat treatment

[0035]

[0036] Note: The data in the table are the average of multiple samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com